JOHNSON CONTROLS

131

SECTION 7 – MAINTENANCE

FORM 155.30-ICOM2.EN.UL

ISSUE DATE: 12/21/2018

7

MANUAL METHOD TO PURGE AIR DIRECTLY

FROM ABSORBER

When the chiller operates at a lower capacity than usual

for a long period of time or when it restarts after a pow-

er failure, the absorber may contain non-condensable

gases. If the machine starts under these conditions, its

performance and efficiency decrease. If this happens,

purge non-condensable gas directly from the absorber

manually according to the following procedure.

1. Set the valves according to pattern B shown in

2. Press the Purge Mode

Manual

button.

3. Press the Manual Purge

ON

button. The vacuum

pump starts. The solenoid valves SV1 and SV2

open.

4. After step 3 begins, confirm that vacuum gauge

stands at 0 ~ 0.15 PSI .abs.

5. Reading the vacuum gauge, open valve V13.

6. Open valve V16 gradually. Confirm that the pres-

sure on the vacuum gauge increases slightly.

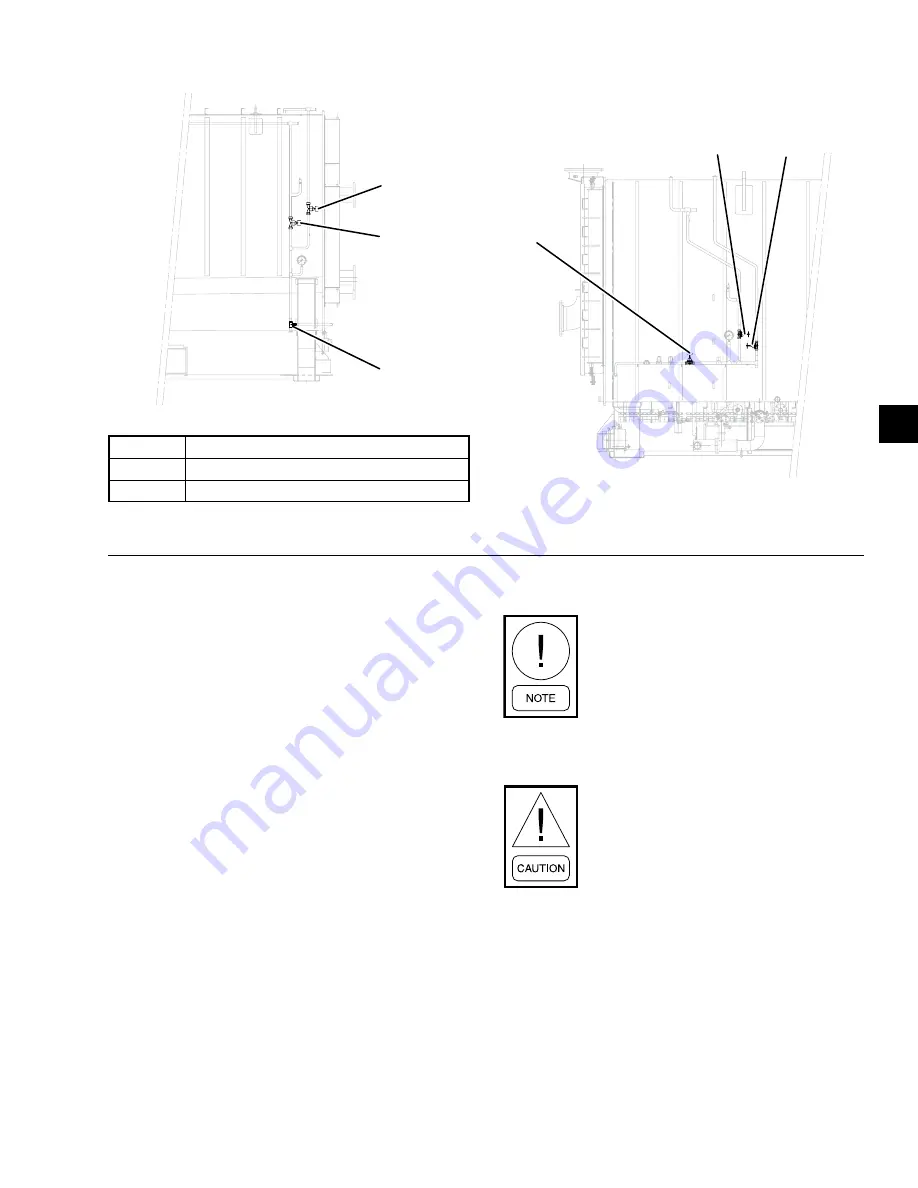

LD19949

EXE Type

EXW2/4ST Type

V16

V11

V14

V16

V11

V14

V11

Purging operating valve for purge tank line

V16

Purging operating valve for absorber line

V14

Purge main valve

FIGURE 58 -

LOCATION OF MANUAL VALVE IN PURGE SYSTEM

NOTE: If the pressure decreases when

valve V16 opens, the vacuum pump capac-

ity is too small. Close valve V16 at once.

See Troubleshooting Performance Issues

on page 159 and check the purge line.

7. If no problems are found, open valve V16 the rest

of the way.

CAUTION: Make sure the valve is com-

pletely open.

8. Continue to purge for 2 to 3 hours.

9. Close valve V13 and V16.

10. Press the Manual Purge

OFF

button. The vacuum

pump stops.

For information on how to set up an automatic purge,

Automatic Method To Purge Non-Condensable Gas

.