JOHNSON CONTROLS

138

FORM 155.30-ICOM2.EN.UL

ISSUE DATE: 12/21/2018

SECTION 7 – MAINTENANCE

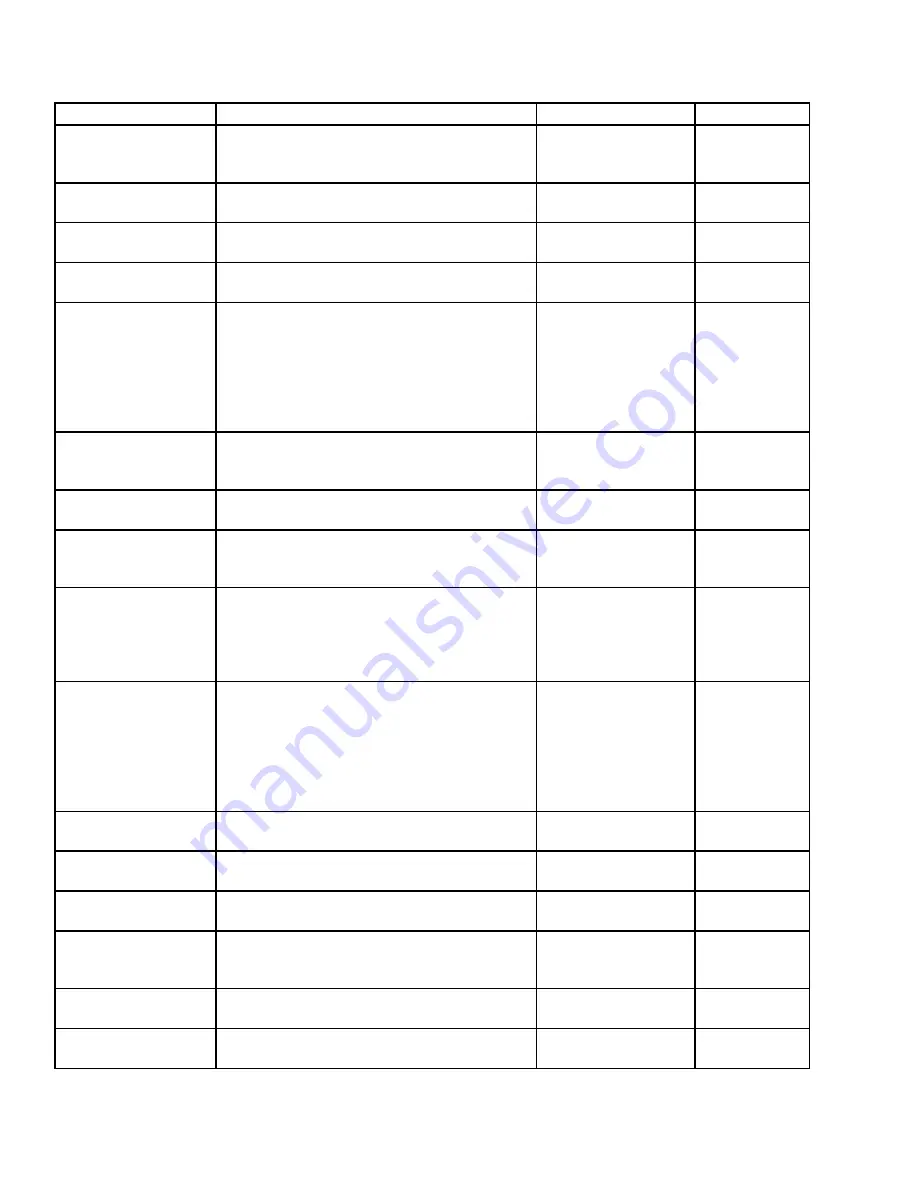

TABLE 29 -

MAINTENANCE AND INSPECTION

TASK

CONTENTS

FREQUENCY

SCOPE

Recording of operation

data

Collect the operation data (Refer to

155.30-CL1

)

and check the data with the data collected during

the factory test.

1 weekly

C

Check of liquid level

See

at each part.

Daily

C

Check of operation of

hot water 3-way valve

Visually check that the hot water 3-way valve is

operating smoothly.

Every 6 months

C

Refine refrigerant

Use the procedure shown in

Every 6 months

S

Manual purging from

purging tank

See

Manually

purge non-condensable gas from the purging tank.

The chiller has an

automatic purge

system. Perform it

once at beginning of

the seasons every year

and once per every 2-3

months.

S

Manual purging from

absorber side

See

purge non-condensable gas from the absorber

side.

Every 2-3 months

S

Replacement of oil in

vacuum pump

Replace the oil in the vacuum pump.

Monthly

C

Check of Vacuum Pump

After the replacement of the lubricant oil for the

vacuum pump, be sure to pull the pulley belt and

check the smooth motion of the pulley.

Monthly

C

Appearance check

Check the outside of the machine for damage

(leakage for chilled water and cooling water,

rusting, or other apparent damage). Check the

solution pump and refrigerant pump for abnormal

sounds and vibration.

Monthly

C

Measurement of

insulation resistance of

electric devices

Measure the insulation resistance of the main

circuit and motors (solution pump, refrigerant

pump) mainly to check for lowering of insulation.

When measuring the insulation resistance, be

sure to disconnect the wires of the temperature

controller, or other wires that may interfere with the

measurement.

Yearly

S

Check of terminals for

looseness

Check each terminal in the control panel for

looseness.

Yearly

S

Check of operation of

control panel

Check the operation of the control panel to prevent

troubles caused by malfunction of the control panel.

Yearly

S

Check of capacity of

purge unit

See

capacity of the purge unit.

Every 6 months

S

Check of leakage

through purge solenoid

valves

By measuring vacuum down speed, check for

leakage through purge solenoid valves.

Yearly

S

Overhaul check of purge

solenoid valves

Perform overhaul of purge solenoid valves.

Yearly

S

Check of airtightness

Measure the quantity of non-condensable gas

discharged from the vacuum pump.

Every 6 months

S

C = Customer and S = Johnson Controls Service