JOHNSON CONTROLS

129

FORM 155.30-ICOM2.EN.UL

ISSUE DATE: 12/21/2018

7

SECTION 7 – MAINTENANCE

When inspecting and maintaining the absorption chill-

er, observe the following items:

• Never splash water over the electrical parts in-

stalled to the control panel and absorption chiller.

• Do not change the set values of the control de-

vices and safety switches without first contacting

you local Johnson Controls Service Office.

• Do not turn the internal cycle control valve of the

absorption chiller without permission.

• When replacing the oil in the vacuum pump, be

sure to turn OFF the main circuit breaker (MCB1)

in the control panel.

VALVE INSPECTION

The chiller is equipped with a refrigerant manual blow

valve (V8) that blows refrigerant from the refrigerant

tank to the absorber directly. See

The refrigerant blow valve must not be tampered with

or the settings changed. The only exception is daily

maintenance and inspection.

WARNING: During service and main-

tenance work, be sure to turn OFF the

main circuit breaker (MCB1) and fully

close the main valve of hot water line. If

not, it may cause electric shock and burn.

CAUTION: Contact your local Johnson

Controls Service Office for inspection and

maintenance of the machine. Improper

inspection and maintenance can not only

cause a machine malfunction or injury.

SOLENOID VALVES

The absorption chiller is equipped with the following

solenoid valves.

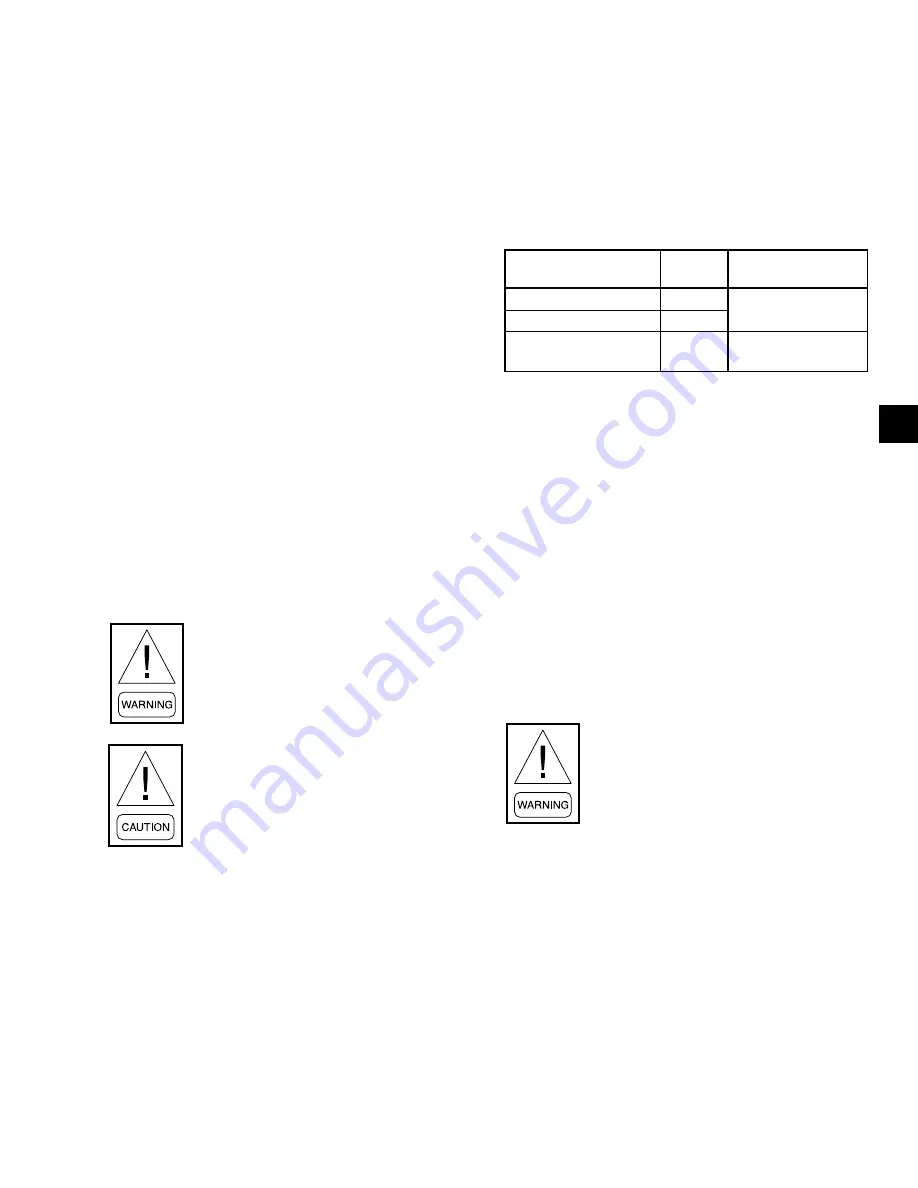

TABLE 28 -

SOLENOID VALVES

SOLENOID VALVE

NAME

SYMBOL

FUNCTION

Purge solenoid valve (1)

SV1

Close vacuum pump

piping

Purge solenoid valve (2)

SV2

Refrigerant blow

solenoid valve

SV3

Close automatic

refrigerant blow piping

PUMP SHUT OFF VALVES

The chiller is equipped with the pump shut off valves

shown in

and

. They are used for inspection of the pumps.

If the absorption chiller is operated with incorrect valve

settings, the pump may be damaged. Do NOT tamper

with the valves.

AIR PURGE VALVES AND DRAIN VALVES

FOR CHILLED WATER, COOLING WATER,

AND HOT WATER

The chiller is equipped with air purge valves and drain

valves for chilled water, cooling water, and hot water.

They are used to drain the chilled water, cooling water,

hot water, and purge air when water is supplied.

WARNING: The installation and inter-

locking of these valves with the chiller

control panel is mandatory for safe and

reliable operation of the chiller and

to prevent potential crystallization of

lithium bromide solution and freezing of

the evaporator tubes.

PURGE VALVES

The chiller is equipped with the purging valves shown

in

and

. For operation of those valves, see

.