JOHNSON CONTROLS

27

SECTION 3 – HANDLING, STORAGE, INSTALLATION AND REASSEMBLY

FORM 155.30-ICOM2.EN.UL

ISSUE DATE: 12/21/2018

3

STRUCTURAL SUPPORT AND INSTALLATION

Structural support of the unit must be provided as indi-

cated for maximum efficiency.

Make sure there is enough maintenance space around

the chiller so work can be performed safely.

Foundation bolts should be installed in level concrete

to secure the unit and prevent shifting in the event of

an earthquake. Rubber vibration isolator pads must be

fit to the machine base before installation as shown on

. The tolerance for leveling is 1

inch in 1,000 inches or 1 mm in 1,000 mm according to

the bottom edge of tube plate.

CAUTION: Waterproof the floor on

which the machine will be installed in

case of future leaks.

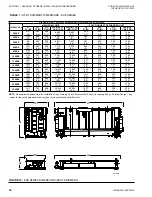

Dimensions can be found in

For

the external dimensions of the machine and founda-

tion, see the full view of the machine and the founda-

tion drawing.

For serviceability and maintenance, leave a minimum

of 40 inch space on all sides of the chiller. To ensure

there is adequate clearance for tube removal, the main-

tenance space at the end of the unit should equal 1.25 x

the length of the unit.

INDOOR AND OUTDOOR INSTALLATION

This chiller is designed to be used indoors. Exposure to

the elements can compromise the integrity of the ther-

mal insulation. Minimum allowable temperature for

outdoor installation is 32°F, provided that the chiller

includes the cold ambient option. Outdoor installations

will be considered on a case-by-case basis by a Johnson

Controls Service Representative.

ELECTRICAL

The electrical work must be performed in accordance

with the wiring diagrams, delivery specifications, and

technical standards for electrical equipment found in

. Use the specified

cables to complete the wiring, and fasten them to the

according terminals securely. Loose fitting cables can

cause the terminals to heat up, resulting in fire or elec-

trical shock.

CAUTION: The chiller does NOT arrive

with a ground fault (earth leakage) cir-

cuit breaker installed. Be sure to have the

customer install one at the primary side

of the unit.

Electrical work must be supervised or completed by a

Johnson Controls Service Representative.

PRECAUTIONS FOR USE

A caution label for a rotating object is pasted around

the belt cover of the vacuum pump. When replacing

the oil in the vacuum pump, belt, or performing main-

tenance work, stop the chiller and be sure to turn off

the main circuit breaker (MCB1) and lockout or tagout

the unit. If this is not done, the vacuum pump could

start abruptly and cause injury or damage to the unit.

Do not place anything heavy on the machine or its

control panel; it may fall and cause injury.

Do not climb up the machine without safety harnessing.

Contact your local Johnson Controls service office for

inspection and maintenance of the machine. Improper

inspection and maintenance may cause a malfunction

or bodily injury.

Keep the chilled water, cooling water, and hot water

under the maximum usage pressure. If they exceed the

maximum usage pressure, they may spout or leak and

may cause an electric leak and a burn.

Do not change the set values of the safety devices and

protective devices. Operation with incorrect set values

can cause a problem.

The shut off valve for the pressure release valve must

remain open except during servicing. The unit must

never be operated with this shut off valve closed.

A caution label for high temperature is pasted at the

control panel, solution pump, and vacuum pump. Be

sure not to touch the pump during pump operation; it

may cause a burn.

Wear protective gloves and goggles when operating

the control valve, and other parts of the chiller.

CAUTION: During service and mainte-

nance work, be sure to turn OFF the main

circuit breaker (MCB1) and follow all re-

quired Lockout/Tagout procedures. Fully

close the main valve to prevent electric

shock and injury.