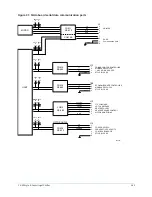

+5VDC signal. In some displays, the backlight turns ON when this signal transitions from low to

high; others turn OFF when it transitions from high to low. The position of Program Jumper JP3

determines the transition that will occur when the microboard outputs the Backlight Enable signal.

JP3 must be positioned according to the display manufacturer’s requirement.

The microboard controls the backlight brightness via the Lamp Dimmer circuit output at J6-7.

In order to extend the life of fluorescent Backlight lamps, the brightness is driven to 50% after

10 minutes of Keypad inactivity. At this brightness level, the graphics are still visible. When

Keypad activity is detected (a key is pressed), the lamp is driven back to full (100%) brightness.

Some display manufacturers require a variable voltage to vary the brightness; others require a

variable resistance. Program Jumpers JP7 and JP8 must be configured to enable the appropriate

technique. The Lamp Dimmer is an integrated circuit that is the electrical equivalent of a 10K

ohm potentiometer with 100 positions or steps. The Lamp Dimmer controls the position of the

potentiometer. The Lamp Dimmer varies the brightness of the backlight by applying a variable

voltage (0 to 5.0VDC) or a variable resistance (0 to 10K ohms) to the Backlight Inverter Board (If

applicable). If Program Jumpers JP7 and JP8 are installed, the Lamp Dimmer output is a variable

voltage; if both are removed, the output is a variable resistance. The Lamp Dimmer outputs

“Brightness Control Wiper” (J6-7) to the Backlight Inverter Board. If configured for variable voltage

output, the voltage between J6-7 and J6-8 can be varied from 0VDC (100% brightness) to 5.0VDC (0%

brightness). If configured for variable resistance, the resistance between J6-6 and J6-7 varies from 0

ohms (0% brightness) to 10K ohms (100% brightness).

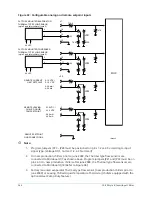

Remote setpoints

Remote Leaving Chilled Liquid Temperature and Current Limit setpoints can be input via the RS-232

SC-EQ communications interface at J2 or directly to the microboard at J22 using a hardwired analog

signal. The inputs at J22 are configured with Program Jumpers JP23 and JP24 to accept these inputs

in either 0 to 10VDC, 2 to 10VDC, 0 to 20mA or 4 to 20mA form.

Configuration/Setup

The following functions are entered as setpoints on the SETUP Screen.

Chilled Liquid Pump Operation –

Determines Chilled Liquid Pump control contacts (I/O Board

TB2- 44/45) operation when chiller shuts down on cycling shutdowns. Selections are:

1.

Standard

– Contacts open at completion of System Coastdown after all shutdowns except

LEAVING CHILLED LIQUID – LOW TEMPERATURE. On this shutdown, they remain closed,

causing the pump to continue to run while the chiller is shutdown.

2.

Enhanced

– Contacts open at completion of System Coastdown after all shutdowns except

LEAVING CHILLED LIQUID – LOW TEMPERATURE, MULTI-UNIT CYCLING – CONTACTS OPEN

and SYSTEM CYCLING – CONTACTS OPEN. On these shutdowns, they remain closed, causing

the pumps to continue to run while the chiller is shutdown.

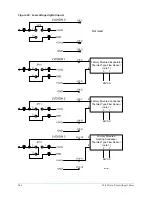

Motor Drive Type –

Configures the program for the applicable Primary compressor motor drive

type. Selections are:

1. EM – Electromechanical Starter

2. SSS-Mod A – Style A Solid State Starter

3. SSS-Mod B – Style B Solid State Starter

4. VSD-60Hz – Variable Speed Drive, 60Hz

5. VSD-50Hz – Variable Speed Drive, 50Hz

6. MVVSD – Medium Voltage VSD

7. MVSSS – Medium Voltage Solid State Starter

YK-EP Style B Centrifugal Chiller

252

Summary of Contents for YK-EP

Page 2: ...2 YK EP Style B Centrifugal Chiller...

Page 6: ...6 YK EP Style B Centrifugal Chiller...

Page 227: ...Figure 72 Sample printout of Status 227 YK EP Style B Centrifugal Chiller...

Page 228: ...Figure 73 Sample printout of Status cont YK EP Style B Centrifugal Chiller 228...

Page 229: ...Figure 74 Sample printout of Setpoints 229 YK EP Style B Centrifugal Chiller...

Page 230: ...Figure 75 Sample printout of Setpoints cont YK EP Style B Centrifugal Chiller 230...

Page 231: ...Figure 76 Sample printout of Schedule 231 YK EP Style B Centrifugal Chiller...

Page 232: ...Figure 77 Sample printout of a Sales order YK EP Style B Centrifugal Chiller 232...

Page 233: ...Figure 78 Sample printout of a Sales order cont 233 YK EP Style B Centrifugal Chiller...

Page 234: ...Figure 79 Sample printout of History YK EP Style B Centrifugal Chiller 234...

Page 235: ...Figure 80 Sample printout of History cont 235 YK EP Style B Centrifugal Chiller...

Page 236: ...Figure 81 Sample printout of a security log report YK EP Style B Centrifugal Chiller 236...