VSD Initialization Failed

Upon application of power, all boards go through the initialization process. At this time, memory

locations are cleared, program jumper positions are checked and serial communications links are

established. There are several causes for an unsuccessful initialization as follows:

•

The Control Center and the VSD must be energized at the same time. The practice of

pulling the fuse in the Control Center to remove power from the Control Center will create a

problem. Power-up must be accomplished by closing the main disconnect on the VSD cabinet

with all fuses in place. A power interruption to the VSD Logic Board will also generate this

message.

•

The eproms must be of the correct version for each VSD board and they must be installed

correctly. The eproms are created as a set, and cannot be interchanged between earlier and

later versions.

•

Serial data communications must be established. See VSD – Serial Communications. If

communications between the VSD Logic Board, Harmonic Filter Logic Board, ACC Board and

Control Center Microboard does not take place during initialization, this message will be

generated. The serial communications can be verified by selecting the VSD DETAILS Screen

from the MOTOR Screen and observing the Full Load Amps value. A zero displayed for this

and other VSD parameters, indicates a serial communications link problem.

•

If the Harmonic Filter option is included, make sure the Filter Logic Board is not in continuous

reset. This condition is evidenced by the Filter Logic Board’s LED’s alternately blinking. The

filter can be eliminated as a cause of initialization failure by disconnecting the filter by placing

switch SW1 on the Filter Logic Board in the OFF position and removing the ribbon cable

between the Filter Logic Board and the VSD Logic Boards.

•

VSD and Harmonic Filter horsepower ratings do not agree.

VSD – High Phase A Instantaneous Current

This shutdown is generated by the VSD if the motor current in phase “A” exceeds a given limit.

The motor current is sensed by the current transformers on the VSD output pole assemblies and

the signals are sent to the VSD Logic Board for processing. Maximum instantaneous permissible

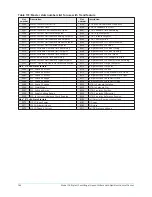

currents are:

•

351/292 HP equals 771 Amps

•

503/419 HP equals 1200 Amps

•

790/658 HP equals 1890 Amps

If an over current trip occurs, but the chiller restarts and runs without a problem, the cause may

be attributed to a voltage sag on the utility power feeding the VSD that is in excess of the specified

voltage range for this product. Thus is especially true if the chiller was running at, or near full load.

If there should be a sudden dip in line voltage, the current to the motor will increase, since the

motor wants to draw constant horsepower. The chiller Pre-rotation Vanes cannot close quickly

enough to correct for this sudden increase in current, and the chiller will trip on an over current

fault.

If the chiller will not restart, but keeps tripping on this same shutdown, an output pole problem is

the most likely cause. The VSD would require service under these conditions.

If this cycling shutdown occurs 3 times in 90 minutes, the third shutdown becomes a safety

shutdown.

Model YK Style H Centrifugal Liquid Chillers with OptiView Control Center

178