JOHNSON CONTROLS

7

FORM 160.75-N3

ISSUE DATE: 04/15/2019

1

INTRODUCTION

This instruction explains the procedure to be used for

reassembling the Model YK Chiller shipped disassem-

bled (Shipping Form 3 and 7).

Chillers MUST be field reassembled un

-

der the supervision of a Johnson Controls

representative.

For instructions on installing the unit, refer to the

In-

stallation - Unit (Form 160.75-N1)

.

FORMS OF SHIPMENT

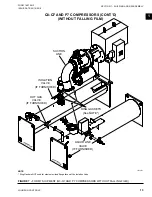

Form 3 – Driveline Separate From Shells –

Shipped

as two major assemblies. The unit is first factory as-

sembled, refrigerant piped, wired and leak tested; then

dismantled for shipment. Close-coupled compressor/

open motor assembly is removed from shells and skid-

ded; however, the evaporator/condenser is not skidded.

All wiring integral with compressor is left on it, and all

conduit is left on the shell. All openings on the com-

pressor and shell are closed and charged with dry ni-

trogen (2 to 3 PSIG).

The shipment may include miscellaneous packaging of the

control center, oil eductor filter, tubing, water temperature

controls, wiring, oil, isolators, solid state starter or variable

speed drive (options). The refrigerant charge is shipped in

appropriate cylinders. For P and Q compressors the control

panel is removed for shipment. For H9 and K compressors

the control panel is shipped on a folded bracket. Refer to

the

Installation - Unit (Form 160.75-N1)

for more details.

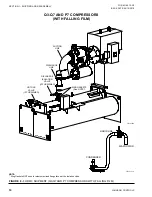

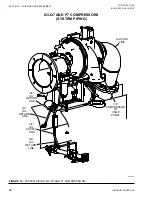

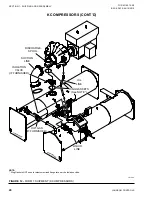

Form 7 – Split Shells –

Shipped as three major assem-

blies. The unit is first factory assembled, refrigerant

piped, wired and leak tested; then dismantled for ship-

ment. Close-coupled compressor/open motor assembly

is removed from shells and skidded.

The evaporator and condenser shells are separated at

tube sheets and are not skidded. The refrigerant lines

between the shells are flanged and capped; tube sheets

are also bolted, requiring NO welding.

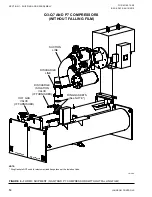

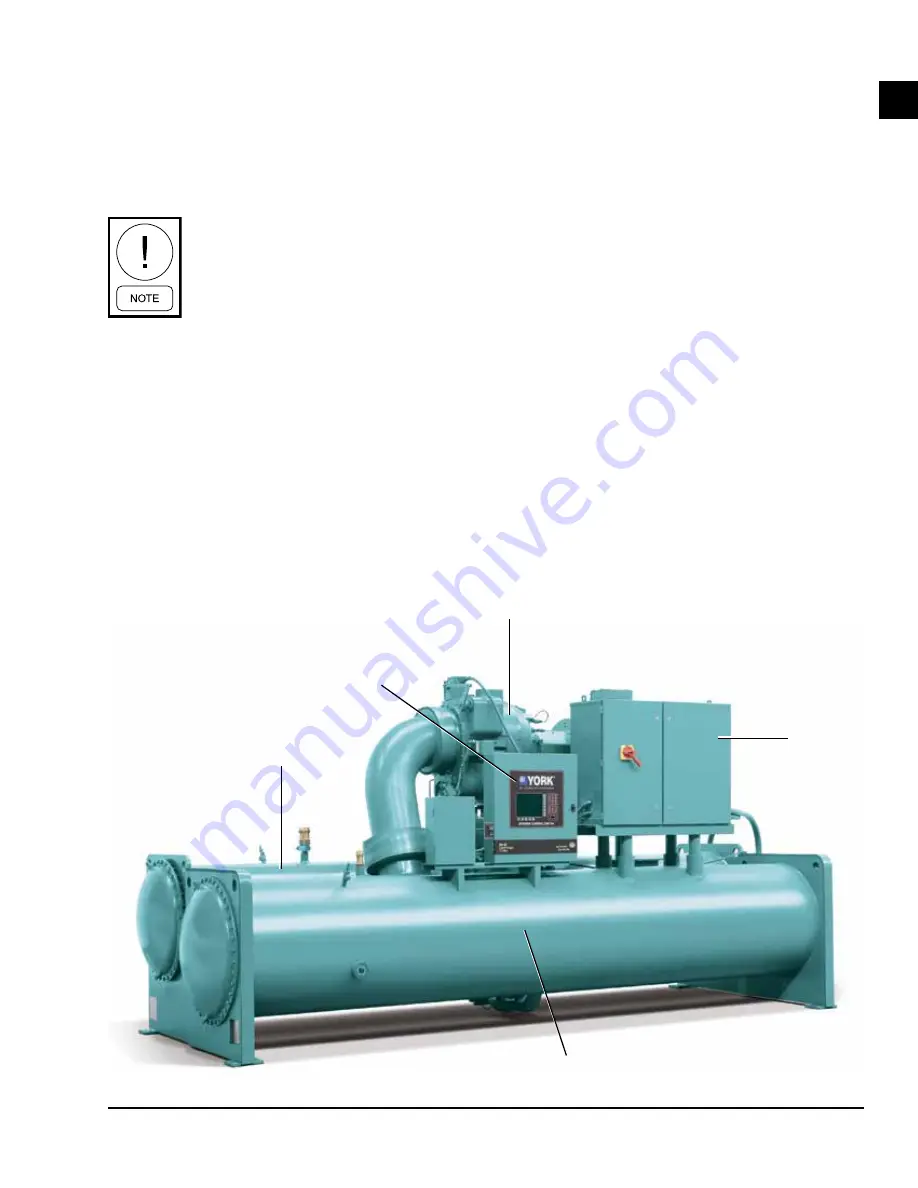

LD15222

CONDENSER

CONTROL

CENTER

COMPRESSOR

MOTOR

EVAPORATOR

FIGURE 1 -

FRONT VIEW OF ASSEMBLED UNIT

SECTION 1 - SHIPPING AND REASSEMBLY