JOHNSON CONTROLS

FORM 160.75-EG1 (519)

76

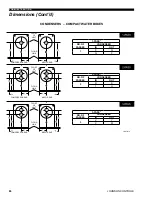

EVAPORATOR

CONDENSER

(SHIPPING WIDTH)

OPTIVIEW™

CONTROL

CENTER

COMPRESSOR

MOTOR

K COMPRESSOR UNITS

Dimensions (Cont'd)

K1 COMPRESSOR, EVAPORATOR-CONDENSER SHELL CODES

DIM

I-K & K-K

M-M

N-N

P-P

Q-Q

A

7' 6-1/2"

(2299)

8' 7"

(2616)

8' 7"

(2616)

9' 1-1/2"

(2781)

9' 1-1/2"

(2781)

B

9' 7"

(2921)

11' 4"

(3454)

11' 4"

(3454)

11' 5-1/2"

(3493)

11' 5-1/2"

(3493)

C

2' 1-1/4"

(641)

2' 4-1/2"

(724)

2' 4-1/2"

(724)

2' 5-1/2"

(749)

2' 5-1/2"

(749)

D

1' 8"

(508)

1' 11"

(584)

1' 11"

(584)

2' 1-1/4"

(641)

2' 1-1/4"

(641)

E

14' 0"

(4267)

14' 0"

(4267)

16' 0"

(4877)

14' 0"

(4267)

16' 0"

(4877)

ADDITIONAL OPERATING HEIGHT CLEARANCE TO FLOOR

TYPE OF CHILLER MOUNTING

M

NEOPRENE PAD ISOLATORS

1 3/4"

(45)

SPRING ISOLATORS 1" DEFLECTION

1"

(25)

DIRECT MOUNT

3/4"

(19)

K2 COMPRESSOR EVAPORATOR-CONDENSER SHELL CODES

DIM

M-M

M-U

N-N

P-P

Q-Q

A

8' 7"

(2616)

9' 6"

(2896)

8' 7"

(2616)

9' 1-1/2"

(2781)

9' 1-1/2"

(2781)

B

11' 4"

(3454)

11' 10"

(3607)

11' 4"

(3454)

11' 5"

(3480)

11' 5"

(3480)

C

2' 4-1/2"

(724)

2' 4-1/2"

(724)

2' 4-1/2"

(724)

2' 5-1/2"

(749)

2' 5-1/2"

(749)

D

1' 11"

(584)

2' 4-1/2"

(724)

1' 11"

(584)

2' 1-1/4"

(641)

2' 1-1/4"

(641)

E

14' 0"

(4267)

14' 0"

(4267)

16' 0"

(4877)

14' 0"

(4267)

16' 0"

(4877)

LD07134

Summary of Contents for YK

Page 4: ...JOHNSON CONTROLS FORM 160 75 EG1 519 4 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 18: ...JOHNSON CONTROLS FORM 160 75 EG1 519 18 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 59: ...FORM 160 75 EG1 519 JOHNSON CONTROLS 59 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 83: ...FORM 160 75 EG1 519 JOHNSON CONTROLS 83 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 91: ...FORM 160 75 EG1 519 JOHNSON CONTROLS 91 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 113: ...FORM 160 75 EG1 519 JOHNSON CONTROLS 113 THIS PAGE INTENTIONALLY LEFT BLANK...