JOHNSON CONTROLS

120

FORM 150.72-ICOM6

ISSUE DATE: 08/03/2022

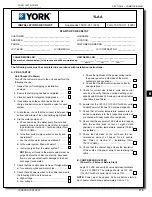

SECTION 6 – COMMISSIONING

SETPOINTS ENTRY LIST

UNIT OPTIONS

Display Language

System 1 Switch

System 2 Switch

Chilled Liquid

Ambient Control*

Local/Remote Mode

Control Mode

Display Units

Lead/Lag Control*

Fan Control*

Manual Override

Power Fail Restart

Soft Start**

Unit Type**

Refrigerant Type**

Flash Card Update

Remote Temperature Reset

External Evaporator Pump

YORK Hydro Kit Pump

Pump Selection

Data Log to Flashcard Enabled

Expansion Valve Type**

COOLING SETPOINTS

Cooling Setpoint

Range

EMS-PWM Max. Setpoint

PROGRAM SETPOINTS

Discharge Pressure Cutout

Suction Pressure Cutout

Low Ambient Temp. Cutout

Leaving Liquid Temp. Cutout

Anti-Recycle Time

Fan Control ON Pressure

Fan Diff erential OFF Pressure

Total # of Compressors

Number of Fans/System*

Unit/System Voltage*

Remote Unit ID

* Not on all models **Viewable only

A. STARTUP

Panel checks (Power On - Both Unit Switch Off )

1. Apply 3-phase power and verify its value. Voltage

imbalance should be no more than 2% of the aver-

age voltage ..............................................................

2. Apply 120 VAC (110 VAC for 50 Hz units) and verify

its value on the terminal block in the Power Panel.

Make the measurement between Terminals 5 and 2

of XTBC2. The voltage should be 120 VAC plus or

minus 10% ..................................................................

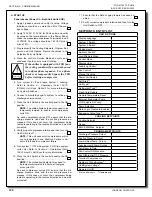

3. Program/verify the Cooling Setpoints, Program Set-

points, and Unit Options. Record the values in the

Setpoints Entry List table ...........................................

4. Place the unit into Service Mode and cycle each

condenser fan to ensure correct rotation ..................

If the chiller is equipped with VSD fans,

the cycling condenser fan can not be used

to confi rm phase sequence. Use a phase

checker or temporarily bypass the VSD

before starting a compressor.

5. Turn system 2 off and leave System 1 running.

Refer to

Section 6 – Operations

(Form 150.72-

ICOM6)

,

Unit Keys

, Option 2 for more information

on System Switches ...................................................

6. Connect a manifold gauge to system 1 suction and

discharge service valves ............................................

7. Place the Unit Switch in the control panel to the ON

position ........................................................................

NOTE:

The chilled liquid setpoint may need to be

temporarily lowered to ensure all compressors

cycle ON.

As each compressor cycles ON, ensure that the dis-

charge pressure rises and the suction pressure de-

creases. If this does not occur, the compressor being

tested is operating in the reverse direction and must be

corrected.

8. Verify proper compressor rotation and then turn the

Unit Switch to off ......................................................

NOTE:

This unit uses scroll compressors, which

can only operate in one direction. Failure to ob-

serve this leads to compressor failure.

9. Turn system 1 OFF and system 2 ON (two system

units only). Refer to

Section 6 – Operations (Form

150.72-Icom6), Unit Keys

for more information ........

10. Place the Unit Switch in the control panel to the ON

position. ......................................................................

NOTE:

The chilled liquid setpoint may need to

be temporarily lowered to ensure all compres-

sors cycle ON.

As each compressor cycles ON, ensure that the dis-

charge pressure rises and the suction pressure de-

creases. If this does not occur, the compressor being

tested is operating in the reverse direction and must be

corrected.

11. Ensure that the Data Logging feature has been en-

abled ............................................................................

12. Verify correct compressor rotation and then turn the

Unit Switch to OFF .....................................................