JOHNSON CONTROLS

113

SECTION 6 – COMMISSIONING

FORM 150.72-ICOM6

ISSUE DATE: 08/03/2022

6

Switch Settings

Ensure the chiller OFF/ON UNIT switch at the bottom

of the keypad is OFF. Place the optional circuit breaker

handle on the panel door to ON. The customer’s dis-

connection devices can now be set to ON.

Verify the control panel display is illuminated.

Ensure

the system switches under the SYSTEM SWITCHES

key are in the OFF position.

Supply Voltage

Verify that the site voltage supply corresponds to the

unit requirement and is within the limits given in

Water System

Verify the chilled liquid system has been installed cor-

rectly, and has been commissioned with the correct

direction of water flow through the cooler. The inlet

should be at the refrigerant piping connection end of

the cooler. Purge air from the top of the cooler using

the plugged air vent mounted on the extension pipe.

Flow rates and pressure drops must be within the limits

given in

. Operation

outside of these limits is undesirable and could cause

damage.

If mains power must be switched OFF for extended

maintenance or an extended shutdown period, the com-

pressor suction, discharge and economizer service stop

valves should be closed (clockwise). If there is a pos-

sibility of liquid freezing due to low ambient tempera-

tures, the coolers should be drained or power should be

applied to the chiller. This will allow the cooler heater

to protect the cooler from freezing down to –20°F. Be-

fore placing the unit back in service, valves should be

opened and power must be switched ON (if power is

removed for more than 8 hours) for at least 8 hours (24

hours if ambient temperature is below 86°F [30°C])

before the unit is restarted.

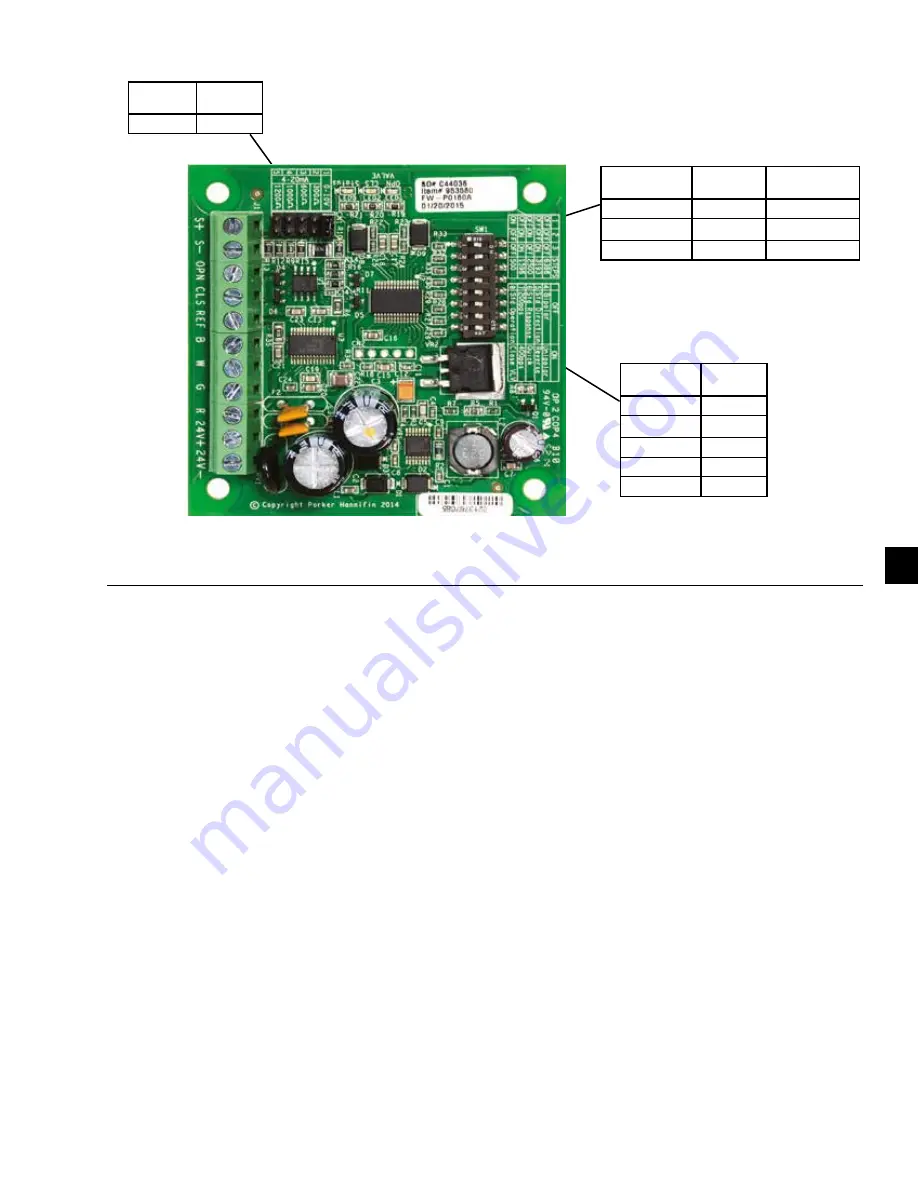

JUMP

LOCATION

INPUT

SIGNAL

1

0–10 V

FIGURE 36 -

EEV IB-G INTERFACE BOARD

LD23530

DIP SWITCH

NUMBER

ALL

CHILLERS

4

OFF

5

OFF

6

ON

7

OFF

8

OFF

DIP SWITCH

NUMBER

YLAA0230

ALL OTHER

CHILLERS

1

OFF

OFF

2

OFF

ON

3

OFF

OFF