35

JOHNSON CONTROLS

FORM 150.72-NM3 (1020)

ISSUE DATE 10/05/2020

3

SECTION 3 – HANDLING AND STORAGE

DELIVERY AND STORAGE

To ensure consistent quality and maximum reliability,

all units are tested and inspected before leaving the

factory. Units are shipped completely assembled and

containing refrigerant under pressure. Units are shipped

without export crating unless crating has been specified

on the Sales Order.

If the unit is to be put into storage, prior to installation,

the following precautions should be observed:

• The chiller must be “blocked” so that the base is

not permitted to sag or bow.

• Ensure that all openings, such as water connec-

tions, are securely capped.

• Do not store where exposed to ambient air tem-

peratures exceeding 110 °F (43 °C).

• The condensers should be covered to protect

the fins from potential damage and corrosion,

particularly where building work is in progress.

• The unit should be stored in a location where

there is minimal activity in order to limit the risk

of accidental physical damage.

• To prevent inadvertent operation of the pres-

sure relief devices the unit must not be steam

cleaned.

• It is recommended that the unit is periodically

inspected during storage.

INSPECTION

Remove any transit packing and inspect the unit to

ensure that all components have been delivered and that

no damage has occurred during transit. If any damage

is evident, it should be noted on the carrier’s freight bill

and a claim entered in accordance with the instructions

given on the advice note.

Major damage must be reported immediately to your

local Johnson Controls representative.

MOVING THE CHILLER

Prior to moving the unit, ensure that the installation site

is suitable for installing the unit and is easily capable

of supporting the weight of the unit and all associated

services.

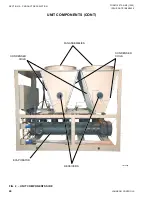

The units are designed to be lifted using cables. A

spreader bar or frame should be used in order to prevent

damage to the unit from the lifting chains.

Units are provided with lifting eyes in the sides of the

base frame, which can be attached to directly using

shackles or safety hooks.

The unit must only be lifted by the base

frame at the points provided. Never

move the unit on rollers, or lift the unit

using a forklift truck.

Care should be taken to avoid damaging the condenser

cooling fins when moving the unit.

Lifting Weights

For details of weights and weight distribution, refer to

the data shipped in the chiller information packet and

unit nameplate.

The unit should be lifted by inserting

hooks through the holes provided in

unit base rails. Spreader bars should

be used to avoid crushing the unit

frame rails with the lifting chains (See

below).

Summary of Contents for YLAA0285SE

Page 57: ...57 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 59: ...59 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 61: ...61 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 65: ...65 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 67: ...67 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 69: ...69 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 71: ...71 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 73: ...73 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 75: ...75 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 77: ...77 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 79: ...79 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 81: ...81 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 83: ...83 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 85: ...85 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 87: ...87 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 91: ...91 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 93: ...93 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 95: ...95 JOHNSON CONTROLS FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 SECTION 5 TECHNICAL DATA 5 5...

Page 204: ...JOHNSON CONTROLS 204 FORM 150 72 NM3 1020 ISSUE DATE 10 05 2020 NOTES...