20

JOHNSON CONTROLS

FORM 150.63-EG4 (1012)

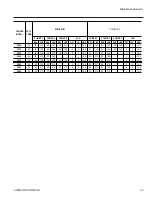

Ratings 50Hz SI

MODEL: YLUA0248YE

AIR TEMPERATURE ON - CONDENSER (°C)

25.0

30.0

35.0

40.0

45.0

KW

KW

COP

KW

KW

COP

KW

KW

COP

KW

KW

COP

KW

KW

COP

2.0

228.9

49.2

4.1

217.5

54.5

3.6

205.3

60.6

3.1

190.3

66.9

2.6

174.8

73.7

2.2

3.0

236.1

49.5

4.2

224.4

54.9

3.6

211.8

61.0

3.1

196.5

67.3

2.7

180.6

74.2

2.2

4.0

243.5

50.0

4.3

231.4

55.3

3.7

218.5

61.4

3.2

202.8

67.7

2.7

186.4

74.7

2.3

5.0

251.0

50.4

4.4

238.6

55.7

3.8

225.4

61.8

3.3

209.2

68.2

2.8

192.4

75.1

2.4

6.0

258.6

50.8

4.5

245.9

56.1

3.9

232.3

62.2

3.4

215.7

68.6

2.9

198.5

75.6

2.4

7.0

266.4

51.3

4.6

253.4

56.6

4.0

239.4

62.7

3.5

222.4

69.0

2.9

204.7

76.0

2.5

8.0

274.3

51.8

4.7

260.9

57.0

4.1

246.6

63.1

3.5

229.2

69.5

3.0

211.0

76.5

2.5

9.0

282.3

52.3

4.8

268.6

57.5

4.2

254.0

63.6

3.6

236.1

70.0

3.1

217.5

77.0

2.6

10.0

290.5

52.8

4.9

276.5

58.0

4.3

261.5

64.1

3.7

243.1

70.5

3.2

224.1

77.5

2.7

11.0

298.8

53.4

5.0

284.5

58.6

4.4

269.1

64.6

3.8

250.3

71.0

3.2

230.7

78.0

2.7

12.0

307.3

54.0

5.1

292.6

59.1

4.4

276.8

65.2

3.9

257.6

71.5

3.3

237.5

78.5

2.8

MODEL: YLUA0278YE

AIR TEMPERATURE ON - CONDENSER (°C)

25.0

30.0

35.0

40.0

45.0

KW

KW

COP

KW

KW

COP

KW

KW

COP

KW

KW

COP

KW

KW

COP

2.0

240.0

55.4

3.9

227.8

61.4

3.3

214.7

68.2

2.9

198.9

75.3

2.4

182.5

83.0

2.0

3.0

247.5

55.8

4.0

235.0

61.9

3.4

221.6

68.7

2.9

205.3

75.8

2.5

188.4

83.5

2.1

4.0

255.1

56.3

4.1

242.3

62.3

3.5

228.5

69.2

3.0

211.8

76.3

2.6

194.5

84.1

2.1

5.0

262.9

56.8

4.1

249.8

62.8

3.6

235.7

69.7

3.1

218.5

76.8

2.6

200.7

84.6

2.2

6.0

270.9

57.3

4.2

257.4

63.3

3.7

242.9

70.2

3.2

225.3

77.4

2.7

207.0

85.2

2.3

7.0

279.0

57.8

4.3

265.1

63.8

3.8

250.3

70.7

3.2

232.2

77.9

2.7

213.5

85.7

2.3

8.0

287.2

58.4

4.4

273.0

64.4

3.8

257.8

71.3

3.3

239.2

78.4

2.8

220.0

86.3

2.4

9.0

295.6

59.0

4.5

281.0

64.9

3.9

265.4

71.8

3.4

246.4

79.0

2.9

226.7

86.9

2.4

10.0

304.0

59.6

4.6

289.1

65.5

4.0

273.2

72.4

3.5

253.7

79.6

2.9

233.5

87.5

2.5

11.0

312.7

60.3

4.7

297.4

66.2

4.1

281.1

73.0

3.5

261.1

80.2

3.0

204.1

68.9

2.7

12.0

321.5

60.9

4.8

305.8

66.8

4.2

289.1

73.6

3.6

268.6

80.8

3.1

210.2

69.3

2.8

MODEL: YLUA0298YE

AIR TEMPERATURE ON - CONDENSER (°C)

25.0

30.0

35.0

40.0

45.0

KW

KW

COP

KW

KW

COP

KW

KW

COP

KW

KW

COP

KW

KW

COP

2.0

261.5

61.9

3.8

247.9

68.5

3.3

233.3

75.9

2.8

215.8

83.7

2.4

197.6

92.1

2.0

3.0

269.7

62.5

3.9

255.6

69.0

3.4

240.6

76.5

2.9

222.6

84.3

2.5

203.9

92.8

2.1

4.0

278.0

63.0

4.0

263.5

69.6

3.5

248.1

77.1

3.0

229.6

84.9

2.5

210.4

93.4

2.1

5.0

286.4

63.7

4.1

271.6

70.2

3.5

255.8

77.7

3.0

236.7

85.5

2.6

217.0

94.1

2.2

6.0

295.0

64.3

4.2

279.8

70.8

3.6

263.6

78.4

3.1

244.0

86.1

2.6

223.7

94.7

2.2

7.0

303.8

64.9

4.2

288.1

71.5

3.7

271.4

79.0

3.2

251.3

86.8

2.7

230.5

95.4

2.3

8.0

312.7

65.6

4.3

296.6

72.2

3.8

279.5

79.7

3.2

258.8

87.5

2.8

237.5

96.1

2.3

9.0

321.8

66.3

4.4

305.2

72.8

3.8

287.6

80.4

3.3

266.4

88.2

2.8

244.5

96.8

2.4

10.0

331.0

67.0

4.5

314.0

73.6

3.9

295.9

81.1

3.4

274.2

88.9

2.9

217.1

78.6

2.6

11.0

340.4

67.7

4.6

322.8

74.3

4.0

304.4

81.8

3.4

282.0

89.6

2.9

223.5

79.1

2.6

12.0

349.9

68.5

4.7

331.9

75.1

4.1

313.0

82.6

3.5

290.0

90.4

3.0

192.5

60.6

2.9

LCWT

(°C)

LCWT

(°C)

LCWT

(°C)

Summary of Contents for YLUA Series

Page 13: ...FORM 150 63 EG4 1012 13 JOHNSON CONTROLS INTENTIONALLY LEFT BLANK ...

Page 36: ...36 JOHNSON CONTROLS FORM 150 63 EG4 1012 Electrical Drawings ...

Page 37: ...FORM 150 63 EG4 1012 37 JOHNSON CONTROLS ...

Page 38: ...38 JOHNSON CONTROLS FORM 150 63 EG4 1012 Electrical Drawings continued ...

Page 39: ...FORM 150 63 EG4 1012 39 JOHNSON CONTROLS ...

Page 40: ...40 JOHNSON CONTROLS FORM 150 63 EG4 1012 Electrical Drawings continued ...

Page 41: ...FORM 150 63 EG4 1012 41 JOHNSON CONTROLS ...

Page 42: ...42 JOHNSON CONTROLS FORM 150 63 EG4 1012 Electrical Drawings continued ...

Page 43: ...FORM 150 63 EG4 1012 43 JOHNSON CONTROLS ...