FORM 150.63-EG4 (1012)

45

JOHNSON CONTROLS

N

O

I

T

P

I

R

C

S

E

D

n

o

it

a

n

g

i

s

e

D

N

O

I

T

P

I

R

C

S

E

D

n

o

it

a

n

g

i

s

e

D

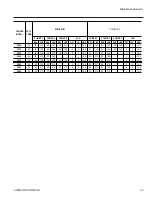

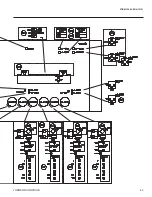

ACC

ACCESSORY

-QCB

CIRCUIT BREAKER

- ADIS

DISPLAY BOARD

-QMMSC

MANUAL MOTOR STARTER COMPRESSOR

P

M

U

P

R

E

T

R

A

T

S

R

O

T

O

M

L

A

U

N

A

M

P

S

M

M

Q

-

D

R

A

O

B

O

R

C

I

M

B

M

A

-

-QSD

SWITCH DISCONNECT

- BAMB

AMBIENT

-BDAT

DISCHARGE AIR TEMPERATURE

R

RESISTOR

D

E

R

D

E

R

E

R

U

S

S

E

R

P

E

G

R

A

H

C

S

I

D

P

D

B

-

- BECT

ENTERING CHILLED TEMPERATURE

RP

RUN PERMISSIVE

- BLCT

LEAVING CHILLED TEMPERATURE

RU

REMOTE UNLOAD Ist STEP

NOT FITTED ON REMOTE EVAP. UNITS

SCH

THERMOSTAT CRANKCASE HEATER

-BMP

MOTOR PROTECTOR COMPRESSOR

SCR

SCREEN

H

C

T

I

W

S

W

O

L

F

F

S

-

E

R

U

S

S

E

R

P

N

O

I

T

C

U

S

P

S

B

-

- SKP

KEYPAD

-CPF

CAPACITOR POWER FACTOR

- SOA

SWITCH OFF AUTO

-SZT

ZONE THERMOSTAT

- ECH

CRANKCASE HEATER

-EEH

EVAPORATOR HEATER

- T

TRANSFORMER

T

N

E

R

R

U

C

R

E

M

R

O

F

S

N

A

R

T

C

T

-

R

E

T

A

E

H

Y

R

E

V

O

C

E

R

T

A

E

H

H

R

H

E

-

-EPH

PUMP HEATER

-EXT

EXTERNAL TO CONTROL PANEL

-UBR

BRIDGE RECTIFIER

- F

FUSE

-WHT

WHITE

P

X

-

T

U

O

T

U

C

E

R

U

S

S

E

R

P

H

G

I

H

P

H

F

-

PLUGS BETWEEN POW./MICRO. SECTION

-FSC

FAN SPEED CONTROLLER

- XTBC

TERMINAL BLOCK CUSTOMER

FAN SPEED INHIBIT TWO SPEED

- XTBF

TERMINAL BLOCK FACTORY

FAN OPTION ONLY

-YESV

EVAPORATOR SOLENOID VALVE

GND

GROUND

-YHGSV

HOT GAS SOLENOID VALVE

G/Y

GREEN / YELLOW

(INCLUDING COIL SUPPRESSOR)

LIQUID LINE SOLENOID VALVE

E

R

N

O

D

E

R

I

W

D

N

A

D

E

T

N

U

O

M

D

L

E

I

F

R

O

T

C

E

N

N

O

C

D

R

A

O

B

G

U

L

P

J

MOTE

EVAP. UNIT

R

O

S

S

E

R

P

M

O

C

R

P

C

Z

-

Y

A

L

E

R

D

R

A

O

B

T

I

U

C

R

I

C

K

-

-KF

(INCLUDING COIL SUPPRESSOR)

-KFH

FAN CONTACTOR HIGH SPEED

(INCLUDING COIL SUPPRESSOR)

-KFL

FAN CONTACTOR LOW SPEED

NOTE WELL {SEE NOTE}

(INCLUDING COIL SUPPRESSOR)

-KFOL

FAN OVERLOAD

-KFS

RELAY FAN SPEED

WIRING AND ITEMS SHOWN THUS

-KH

HEATER RELAY

ARE STANDARD YORK ACCESSORIES

-KM

COMPRESSOR CONTACTOR

(INCLUDING COIL SUPPRESSOR)

WIRING AND ITEMS SHOWN THUS

-KCR

CONTROL RELAY

ARE NOT SUPPLIED BY YORK

-KP

PUMP CONTACTOR PART

(INCLUDING COIL SUPPRESSOR)

ITEMS THUS ENCLOSED FORM A

-KT

RELAY TIMER

COMPONENTS OR SETS OFCOMPONENTS

- M

COMPRESSOR MOTOR

-MF

MOTOR FAN

-MP

MOTOR PUMP

NU

NOT USED

PE

PROTECTIVE EARTH

PWM

PULSE WIDTH MODULATION TEMP

RESET or REMOTE UNLOAD 2nd STEP

- YLLSV

-FSI

NB

GENERAL

a.

THIS DRAWING IS BASED ON IEC SYMBOLS.

b.

FIELD WIRING TO BE IN ACCORDANCE WITH THE RELEVANT ELECTRICAL CODE AS WELL AS ALL OTHER

APPLICABLE CODES AND SPECIFICATIONS

c.

ALL SOURCES OF SUPPLY SHOWN ON THIS DIAGRAM TO BE TAKEN FROM ONE MAIN ISOLATOR, NOT

SHOWN OR SUPPLIED BY YORK.

d.

GREEN AND YELLOW WIRE IS USED FOR EARTH, MULTI-COLOURED CABLE USED FOR LOW VOLTAGE.

RED WIRE USED FOR A.C. CONTROL, BLUE WIRE FOR NEUTRAL, BLACK WIRE FOR A.C. AND D.C.

POWER. ORANGE WIRE SHOULD BE USED FOR INTERLOCK CONTROL WIRING SUPPLIED BY EXTERNAL

SOURCE.

e.

LEGEND DESIGNATION DEPICTS COMPONENT ABBREVIATIONS. NUMBER PREFIX LOCATED, IF

APPLICABLE, ON SCHEMATIC CIRCUIT, REFERS TO SYSTEM THEREON, E.G.= 1-FHP2 REFERS TO HIGH

PRESSURE CUTOUT NO 2 ON SYSTEM NO 1.

f.

ALL WIRING TO CONTROL SECTION VOLTAGE FREE CONTACTS REQUIRES A SUPPLY PROVIDED BY THE

DERIVING THE SUPPLIES FOR THE VOLTAGE FREE TERMINALS WITH REGARD TO A COMMON POINT OF

ISOLATION. THUS, THESE CIRCUITS WHEN USED MUST BE FED VIA THE COMMON POINT OF ISOLATION

THE VOLTAGE TO THESE CIRCUITS IS REMOVED WHEN THE COMMON POINT OF ISOLATION TO THE UNIT

IS OPENED. THIS COMMON POINT OF ISOLATION IS NOT SUPPLIED BY YORK. THE YORK VOLTAGE

FREE CONTACTS ARE RATED AT 100VA. ALL INDUCTIVE DEVICES {RELAYS} SWITCH BY THE YORK

VOLTAGE FREE CONTACTS MUST HAVE THEIR COIL SUPPRESSED USING STANDARD R/C SUPPRESSORS.

g.

CUSTOMER VOLTAGE FREE CONTACTS CONNECTED TO TERMINAL 13 MUST BE RATED AT 30V 5ma

NO CONTROLS {RELAYS ETC.} SHOULD BE MOUNTED IN ANY SECTION OF THE CONTROL PANEL.

ADDITIONALLY, CONTROL WIRING NOT CONNECTED TO THE YORK CONTROL PANEL SHOULD NOT BE RUN

THROUGH THE PANEL.

IF THESE PRECAUTIONS ARE NOT FOLLOWED, ELECTRICAL NOISE COULD CAUSE MALFUNCTIONS OR

DAMAGE TO THE UNIT AND ITS CONTROLS.

I.

120/14.3 - (SIGNAL IN/OUT) I.E. 120 IS WIRE # AND 14.3 REFERS TO SHT. 14 COLUMN 3

h.

NOTES

1

REFER TO INSTALLATION COMMISIONING OPERATION AND MAINTENANCE MANUAL FOR CUSTOMER

CONNECTIONS AND CUSTOMER CONNECTION NOTES, NON COMPLIANCE TO THESE INSTRUCTIONS WILL

INVALIDATE UNIT WARRANTY.

2

WIRING AND COMPONENTS FOR COMPRESSOR 3 ONLY FITTED WHEN UNIT HAS 3 COMPRESSORS ON

THE SYSTEM. 1-BMP3 IS REPLACED BY A LINK ACROSS TERMINALS 134 & 135. 2-BMP3 IS REPLACED BY A

LINK ACROSS TERMINALS 234 & 235.

3

FHP2 IS ONLY FITTED ON CE YLAA0180 AND ABOVE. WHEN NOT FITTED 1-FHP2 IS REPLACED BY A LINK

ACROSS TERMINALS 132 & 139. 2-FHP2 IS REPLACED BY A LINK ACROSS TERMINALS 232 & 239

4

FITTED ON UNITS WITH HOT GAS BYPASS OPTION.

5

EMS OPTION IS WIRED AS SHOWN

6

THIS WIRING MUST BE USED FOR OLD DISPLAY 031-0110-000

7

NETWORK CONNECTION POINT

8

PRINTER PORT

9

REMOTE EMERGENCY STOP CAN BE WIRED BETWEEN TERMINAL L AND 5 AFTER REMOVING LINK

10

POWER FACTOR CORRECTION ACCESSORY. POWER FACTOR CORRECTION FITTED TO EACH

COMPRESSOR CONTACTOR

11

NOT FITTED ON COMPRESSORS WITH INTERNAL MOTOR PROTECTION. FOR SYSTEM 1 TERMINALS 132 &

133, 133 & 134 AND 134 & 135 ARE LINKED. FOR SYSTEM 2 TERMINALS 232 & 233, 233 & 234 AND 234 & 235

ARE LINKED.

12

ONLY FITTED ON SYSTEMS WITH 3 OR 4 FANS

13

ONLY FITTED ON SYSTEMS WITH 4 FANS

14

ONLY FITTED ON SYSTEMS WITH 5 FANS

15

ONLY FITTED ON SYSTEMS WITH 6 FANS

16

INPUT SWITCH DISCONNECT ( STANDARD ON CE UNITS) OR CIRCUIT BREAKER OPTION REPLACES

INPUT TERMINAL BLOCK

17

INPUT SWITCH DISCONNECT & INDIVIDUAL SYSTEM CIRCUIT BREAKER OPTION REPLACES INPUT

TERMINAL BLOCK

18

115V CONTROL CIRCUIT REQUIRES A 115V SUPPLY UNLESS CONTROL CIRCUIT TRANSFORMER

-T2 & -F3 ARE FITTED (STANDARD ON CE UNITS)

19

FOR OPTIONAL HYDRO KIT. HEATER -EPH IS FITTED AND WIRED AS SHOWN.

ON SINGLE PUMP -KP1, -QMMSP1 & -MP1 ARE FITTED & WIRED AS SHOWN.

ON TWO PUMP HYDRO KITS -KP2, -QMMSP2 & -MP2 ARE ALSO FITTED AND WIRED AS SHOWN.

20

CURRENT MEASUREMENT OPTION WIRED AS SHOW

21

ONLY FITTED ON SYSTEMS WITH SINGLE SPEED FANS

22

ONLY FITTED ON SYSTEMS WITH TWO SPEED FANS

23

OPTIONAL COMPRESSOR MANUAL MOTORS STARTERS ( STANDARD ON CE UNITS)

24

SEE SHEET 3 OF CONNECTION DIAGRAM FOR POWER INPUT OPTIONS

25

ALTERNATE CONNECTIONS SHOWN FOR DIFFERENT TWO SPEED MOTOR TYPES

26

ONLY FITTED ON SYSTEMS WITH A MAXIMUM OF 4 FANS

27

220/230V UNITS REQUIRE A SEPARATE FUSE FOR UNITS W/4 OR MORE FANS PER SYSTEM

28

LOW AMBIENT KIT -FSC FOR FAN -MF1 IS ONLY FITTED ON SYSTEMS WITH LESS THAN 4 FANS

29

ONLY FITTED ON YLAA0091

30

ONLY FITTED ON YLAA0090,0091, 0135

31

INPUT DUAL POINT CIRCUIT BREAKER OPTION REPLACES INPUT TERMINAL BLOCK

32

FIELD INSTALLED ON REMOTE EVAPORATOR UNITS

33

FITTED ON UNITS WITH SINGLE PHASE MOTORS ONLY

34

FITTED ON UNITS WITH LOW AMBIENT OPTION ONLY

35

ONLY FITTED ON UNITS WITH AN ACOUSTIC KIT

36

ONLY FITTED ON HEAT RECOVERY UNITS

37

ONLY FITTED ON CONDENSING UNITS

38

OMITTED ON CONDENSING UNITS

Summary of Contents for YLUA Series

Page 13: ...FORM 150 63 EG4 1012 13 JOHNSON CONTROLS INTENTIONALLY LEFT BLANK ...

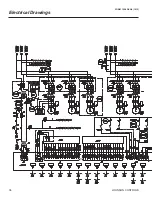

Page 36: ...36 JOHNSON CONTROLS FORM 150 63 EG4 1012 Electrical Drawings ...

Page 37: ...FORM 150 63 EG4 1012 37 JOHNSON CONTROLS ...

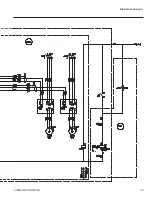

Page 38: ...38 JOHNSON CONTROLS FORM 150 63 EG4 1012 Electrical Drawings continued ...

Page 39: ...FORM 150 63 EG4 1012 39 JOHNSON CONTROLS ...

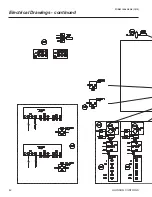

Page 40: ...40 JOHNSON CONTROLS FORM 150 63 EG4 1012 Electrical Drawings continued ...

Page 41: ...FORM 150 63 EG4 1012 41 JOHNSON CONTROLS ...

Page 42: ...42 JOHNSON CONTROLS FORM 150 63 EG4 1012 Electrical Drawings continued ...

Page 43: ...FORM 150 63 EG4 1012 43 JOHNSON CONTROLS ...