JOHNSON CONTROLS

19

Section 3 - Maintenance

Form 160.78-O1

Issue date: 05/19/2021

3

the shells. If a source of hot water is not readily

available, use a portable water heater.

Do not use

steam.

Connect a hose between the source of hot water

under pressure and the evaporator head drain con-

nection, out the evaporator vent connection, into

the condenser head drain, and out the condenser

vent. To avoid the possibility of causing leaks,

raise the temperature slowly so that the tubes and

shell are heated evenly.

5. Close the system charging valve and the stop

valve between the vacuum indicator and the vac-

uum pump. Then disconnect the vacuum pump

leaving the vacuum indicator in place.

6. Hold the vacuum obtained in

Step 3

above in the

system for 8 hours; the slightest rise in pressure

indicates a leak or the presence of moisture, or

both. If after 24 hours the wet bulb temperature

in the vacuum indicator has not risen above 40°F

(4.4°C) or a pressure of 6.3 mm Hg, the system

may be considered tight.

Be sure the vacuum indicator is valved off

while holding the system vacuum and be

sure to open the valve between the vacuum

indicator and the system when checking

the vacuum after the 8 hour period.

7. If the vacuum does not hold for 8 hours within the

limits specified in

Step 6

, the leak must be found

and repaired.

Vacuum dehydration

To obtain a sufficiently dry system, use the following

procedure to evacuate and dehydrate a system in the

field. Although there are several methods of dehydrat-

ing a system, this method produces some of the best

results and provides accurate readings as to the extent

of dehydration.

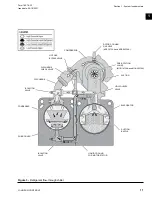

The equipment required to follow this method of de-

hydration consists of a wet bulb indicator or vacuum

gauge, a chart showing the relation between dew point

temperature and pressure in inches of mercury in a

vacuum (see

), and a vacuum pump capable of

pumping a suitable vacuum on the system.

Operation

A refrigerant system can be dehydrated using this

method because the water present in the system reacts

to changes in a similar way that a refrigerant does.

By pulling down the pressure in the system to a point

where its saturation temperature is considerably be-

low room temperature, heat will flow from the room

through the walls of the system and vaporize the water,

allowing a large percentage of it to be removed by the

vacuum pump. The length of time necessary for the de-

hydration of a system depends on the size or volume of

the system, the capacity and efficiency of the vacuum

pump, the room temperature and the quantity of water

present in the system. By the use of the vacuum indi-

cator as suggested, the test tube will be evacuated to

the same pressure as the system, and the distilled water

will be maintained at the same saturation temperature

as any free water in the system, and this temperature

can be observed on the thermometer.

If the system has been pressure tested and found to be

tight before evacuation, then the saturation temperature

recordings should follow a curve similar to the satura-

tion curve shown in

.

The temperature of the water in the test tube will drop

as the pressure decreases, until the boiling point is

reached, at which point the temperature will level off

and remain at this level until all of the water in the

shell is vaporized. When this final vaporization has

taken place the pressure and temperature will continue

to drop until eventually a temperature of 35°F (1.6°C)

or a pressure of 5 mm Hg is reached.

LD00474

Figure 6 -

Saturation curve

Summary of Contents for YMC2 A

Page 12: ...JOHNSON CONTROLS 12 Form 160 78 O1 Issue date 05 19 2021 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 16: ...JOHNSON CONTROLS 16 Form 160 78 O1 Issue date 05 19 2021 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 26: ...JOHNSON CONTROLS 26 Form 160 78 O1 Issue date 05 19 2021 THIS PAGE INTENTIONALLY LEFT BLANK ...