16

JOHNSON CONTROLS

FORM 155.19-EG3 (1011)

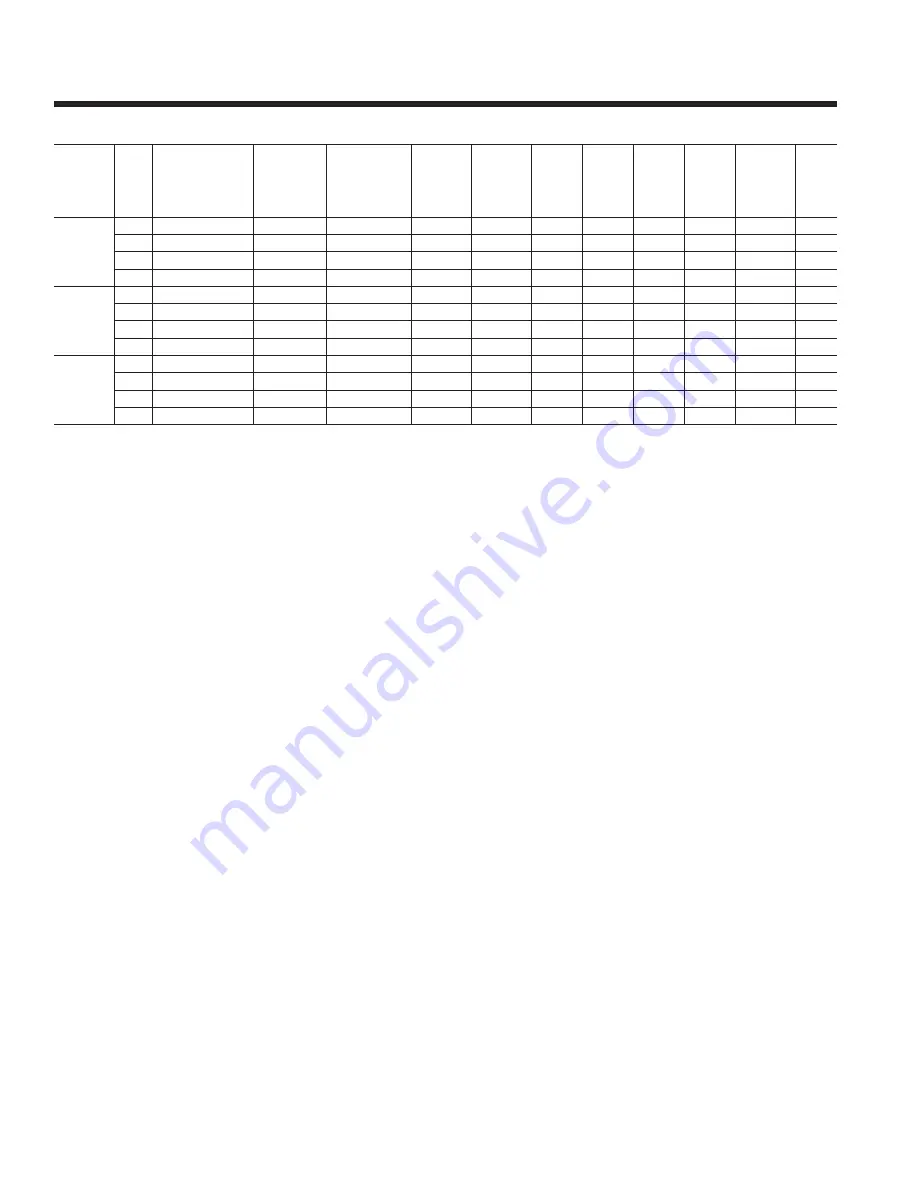

Application Data ‑ continued

TABLE 2

– ELECTRICAL DATA

CHILLER

MODEL

VOLT.

CODE

VOLTAGE

WIRE

AMPACITY

NON‑FUSED

DISCONNECT

SWITCH

MAX

DUAL

ELEMENT

FUSE

SOLU‑

TION

PUMP

FLA

SPRAY

PUMP

FLA

REFRIG

PUMP

FLA

PURGE

PUMP

FLA

ELEC

PANEL

FLA

TOTAL

CURRENT

TOTAL

KW

14SC

-17

200/208V-3PH-60Hz

43.7

60A/240V

60/250V

22

—

6.2

1.7

5

34.9

7.4

-28

230-3PH-60Hz

39.4

60A/240V

50/250V

20

—

5.6

1.5

4.3

31.4

7.4

-50

380V-3PH-50Hz

22.3

30A/480V

30/600V

11.2

—

3.1

0.9

2.6

17.8

7.5

-46

460V-3PH-60Hz

19.8

30A/480V

25/600V

10

—

2.8

0.8

2.2

15.8

7.4

16SL, 17S

18S

-17

200/208V-3PH-60Hz

76.7

100A/240V

125A/250V

36.8

12

12

1.7

5

67.5

15.5

-28

230-3PH-60Hz

75.8

100A/240V

100A/250V

36.8

12

12

1.5

4.3

66.6

15.5

-50

380V-3PH-50Hz

41.3

60A/480V

60A/600V

19

7

7

0.9

2.6

36.5

16.2

-46

460V-3PH-60Hz

38

60A/480V

50A/600V

18.4

6

6

0.8

2.2

33.4

15.5

19S

-17

200/208V-3PH-60Hz

94.7

200A/240V

125A/250V

36.8

30

12

1.7

5

85.5

20.1

-28

230-3PH-60Hz

93.8

100A/240V

125A/250V

36.8

30

12

1.5

4.3

84.6

20.1

-50

380V-3PH-50Hz

51.3

60A/480V

60A/600V

19

17

7

0.9

2.6

46.5

21.2

-46

460V-3PH-60Hz

47

60A/480V

60A/600V

18.4

15

6

0.8

2.2

42.4

20.1

NOTES:

1. Incoming wire to chiller must be copper only. Aluminum wiring is not permitted.

2. Lugs in Power Panel will accept incoming wire range of #14 AWG through #1 AWG.

3. Electrical system must be securely guarded.

4. Field wiring must conform to NEC and all other applicable local codes.