4

JOHNSON CONTROLS

FORM 155.19-EG3 (1011)

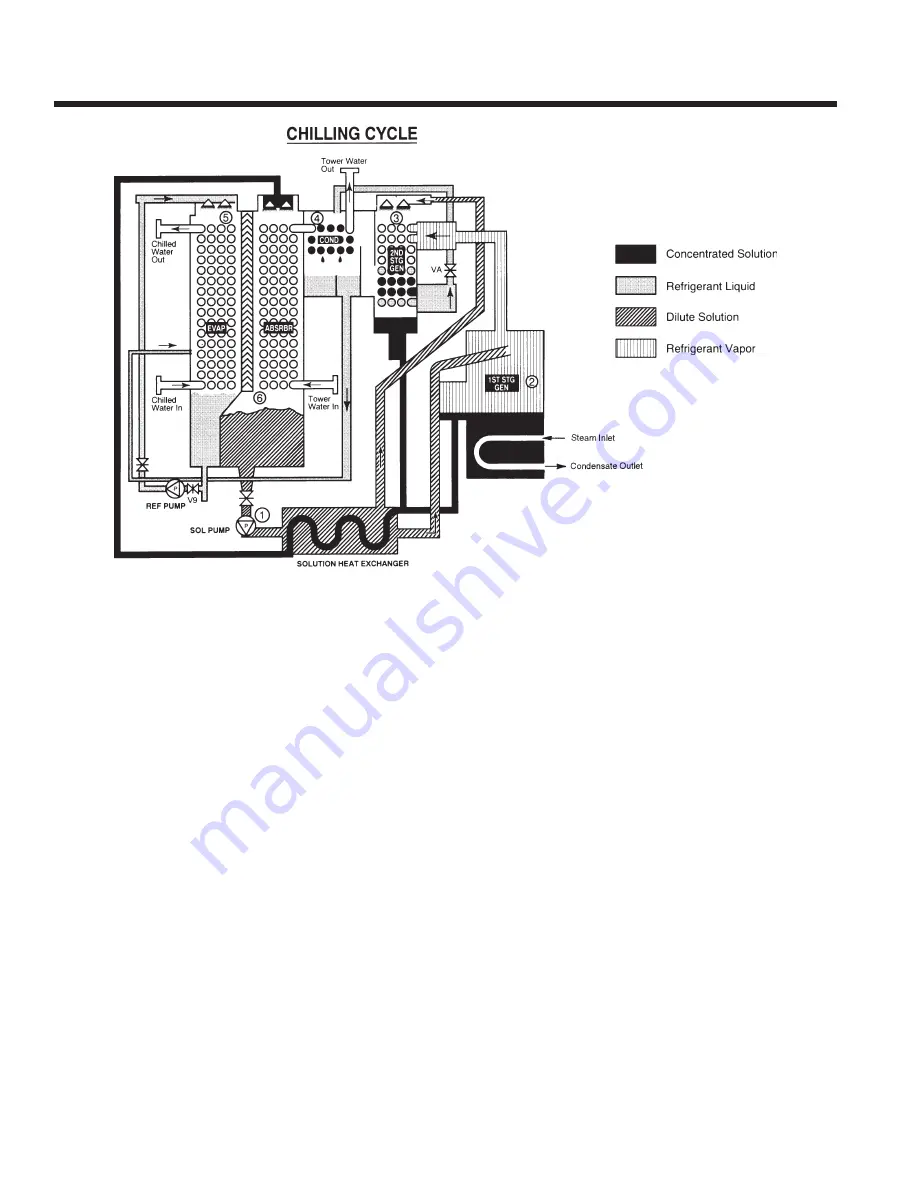

How It Works

STEAM MACHINES

YPC Two-Stage Absorption’s remarkably efficient two-

stage absorption refrigeration cycle uses water as the

refrigerant and lithium-bromide (LiBr) as the absorbent. It

is the strong affinity these two substances have for each

other that makes the cycle work. The entire process oc

-

curs in hermetic vessels in an almost complete vacuum.

The large diagram above indicates the complete chilling

cycle. The six steps are detailed below, with correspond

-

ing numbers in the diagram to show where each step

takes place. YPC’s absorption chilling cycle is continuous;

however, for the sake of clarity and simplicity, it is divided

into six steps.

1. Solution Pump/Heat Exchangers

A dilute solution (58.3%) of LiBr and water descends from

the Absorber to the Solution Pump. This flow of dilute

solution is split into two streams and pumped through

heat exchangers to the First-Stage Generator and to the

Second-Stage Generator.

YPC’s exclusive two-way split of solution flow virtually

eliminates the possibility of crystallization (solidification)

by allowing the unit to operate at much lower solution

concentration and temperatures than series flow systems.

2. First‑stage Generator

An outside steam source heats dilute LiBr (58.3%) coming

from the Solution Pump/Heat Exchangers. This produces

hot refrigerant vapor which is sent to the Second-Stage

Generator, leaving a concentrated solution (63.8%) that

is returned to the Heat Exchangers.

3. Second‑Stage Generator

The energy source for the production of refrigerant vapor

in the Second-Stage Generator is the hot refrigerant vapor

produced by the First-Stage Generator.

This is the heart of the remarkably efficient two-stage

absorption effect. The refrigerant vapor produced in the

first-stage Generator is increased by 40% – at no addi

-

tional expense of fuel. The result is much higher efficiency

than in conventional systems.

This additional refrigerant vapor is produced when dilute

solution from the Heat Exchanger is heated by refriger

-

ant vapor from the First-Stage Generator. The additional

concentrated solution that results is returned to the Ex

-

changer. The refrigerant vapor from the first-stage Genera

-

tor condenses into liquid giving up its heat, and continues

to the Condenser.