JOHNSON CONTROLS

36

FORM 160.81-NOM1

ISSUE DATE: 10/3/2020

SECTION 1 – INSTALLATION

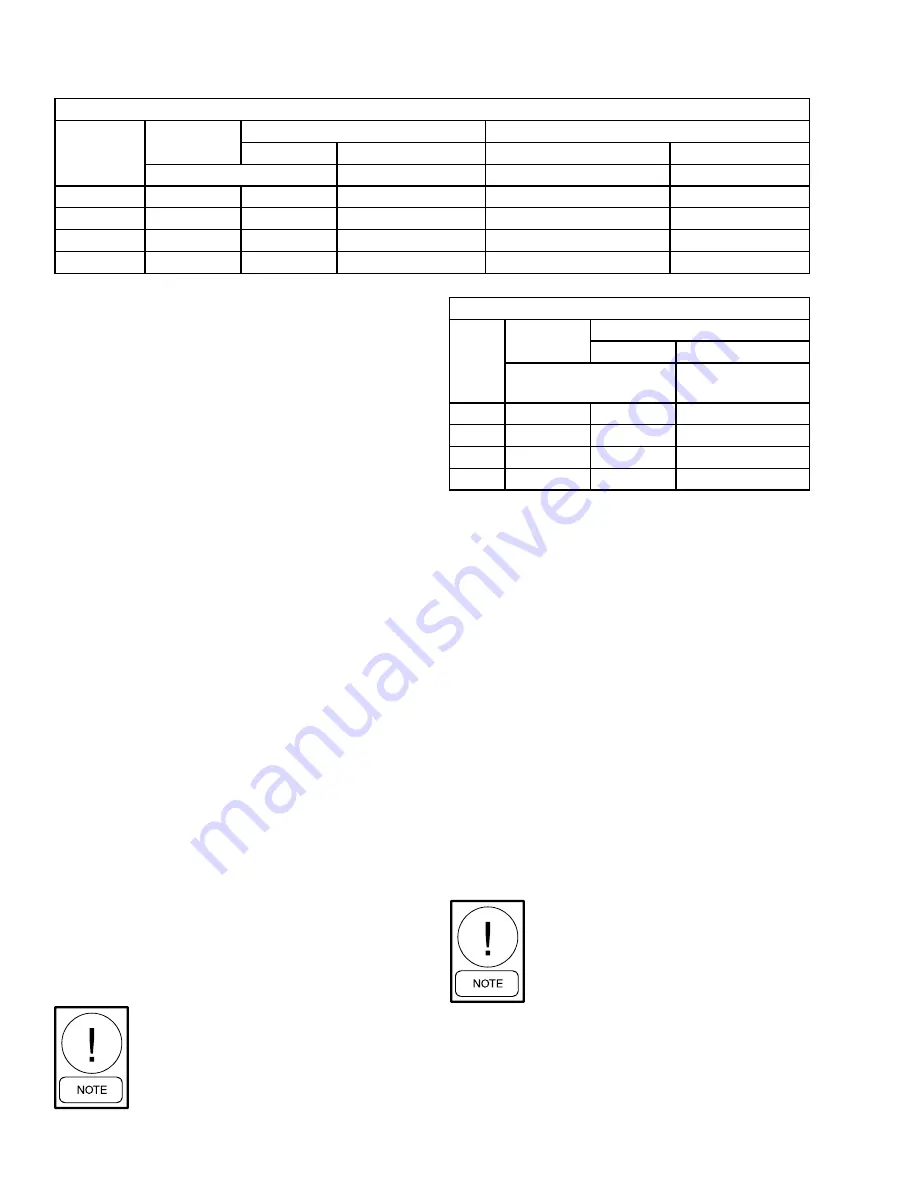

CONDENSER

SHELL

CODE

C

DUAL RELIEF VALVE

1

CR

OUTLET

LBS. AIR PER

MIN. (kPa)

NPT

T

42.1 (290.3) 55.9 (385.4)

1-11-1/2 (FEM)

V

53.8 (370.9) 55.9 (385.4)

1-11-1/2 (FEM)

W

59.4 (409.5) 91.8 (632.9) 1-1/4 - 11-1/2 (FEM)

X

73.3 (505.4) 91.8 (632.9) 1-1/4 - 11-1/2 (FEM)

NOTES:

1. Dual relief valve consists of one three-way shut-off valve and two single relief valves. The valve configuration will not allow both valves

to be shut off at the same time, and valves are sized such that each relief valve has sufficient discharge capacity when used alone. This

permits safe removal of either relief valve for repair or replacement, while maintaining vessel protection.

2. ASHRAE 15-1994 Section 9.8 and Appendix F describes relief requirements for positive dis placement compressors. Summarized, the unit

must be equipped with a relief device suitable for relieving the entire compressor capacity.

Where:

Cr = Rated capacity of YORK supplied relief valve at

235 PSIG.

Relief valve set pressure - 235 PSIG (1,621 kPa).

UNIT PIPING

Compressor lubricant piping and system refrigerant

piping are factory installed on all units shipped assem-

bled. On units shipped dismantled, the following pip-

ing should be completed under the supervision of the

Johnson Controls Representative; the lubricant piping;

system oil return using material furnished.

CONTROL WIRING

After installation of the control center on units shipped

disassembled, the control wiring must be completed

between unit components and control center or solid

state starter when used, using the wiring harness fur-

nished.

Field wiring connections for commonly encountered

control modifications (by others), if required, are

shown on

Wiring Diagram (Form 160.81‑PW5)

.

No deviations in unit wiring from that

shown on drawings furnished shall be

made without prior approval of the John-

son Controls Representative.

POWER WIRING

Unit With Electro-Mechanical Starter

A 115 volt – single-phase – 60 or 50 Hertz power sup-

ply of 15 amperes must be furnished to the control cen-

ter, from the control transformer (1-1/2 kVa required)

included with the compressor-motor starter. DO NOT

make final power connections to control center until

approved by Johnson Controls Representative. Refer

to

Wiring Diagram (Form 160.81‑PW3)

,

Power Wir‑

ing.

Johnson Controls recommends that all connec-

tions to the unit be flexible. Consult with and conform

to all local regulatory requirements.

Remote Electro-Mechanical Starters for

the YR Unit must be furnished in accor-

dance with YORK Standard.

Each YR unit is furnished for a specific electrical pow-

er supply as stamped on the unit data plate, which also

details the motor connection diagrams.

TABLE 11 -

REFRIGERANT RELIEF CHARACTERISTICS

EVAPORATOR

SHELL

CODE

C

SINGLE RELIEF VALVE

DUAL RELIEF VALVE

1

CR

OUTLET

CR

OUTLET

LBS. AIR PER MIN. (kPa)

NPT

LBS. AIR PER MIN. (kPa)

NPT

T

34.7 (239.3)

55.9 (385.4)

1-11-1/2 (FEM)

55.9 (385.4)

1-11-1/2 (FEM)

V

48.5 (334.4)

55.9 (385.4)

1-11-1/2 (FEM)

55.9 (385.4)

1-11-1/2 (FEM)

W

48.0 (330.9)

91.8 (632.9)

1-1/4 - 11-1/2 (FEM)

91.8 (632.9)

1-1/4 - 11-1/2 (FEM)

X

64.0 (441.3)

91.8 (632.9)

1-1/4 - 11-1/2 (FEM)

91.8 (632.9)

1-1/4 - 11-1/2 (FEM)