• Drain and air vent connections must be provided at all low and high points in the piping to

facilitate drainage of the system and to vent any air in the pipes.

• Use insulation and heater tape or a suitable glycol solution to protect liquid system lines that

are at risk of freezing due to low ambient temperatures. Use the liquid pumps to ensure that

liquid is circulated when the ambient temperature approaches freezing point.

• Install insulation around the evaporator nozzles. Use heater tape of 21 W/m under the

insulation, supplied independently, and controlled by an ambient temperature thermostat set

to switch on at approximately 4°F (2.2°C) above the freezing temperature of the chilled liquid.

• Evaporator heater mats are installed under the insulation, and are powered from the chiller's

HTR DIST panel. In sub-freezing conditions, unless the evaporator has been drained or an

appropriate water-to-glycol concentration is maintained, high voltage power to the chiller must

be maintained to ensure the heater mats assist in evaporator freeze protection. If there is a

potential for power loss, drain the evaporator or replace the water in the chilled water circuit

with an appropriate water-to-glycol concentration.

CAUTION

Any debris left in the water piping between the strainer and evaporator could cause serious damage

to the tubes in the evaporator and must be avoided. Be sure the piping is clean before connecting it to

the evaporator. Keep evaporator nozzles and chilled liquid piping capped before installation to ensure

construction debris is not allowed to enter.

CAUTION

The installer or user must also ensure that the quality of the water in circulation is adequate, without

any dissolved gases, which can cause oxidation of steel or copper parts within the evaporator.

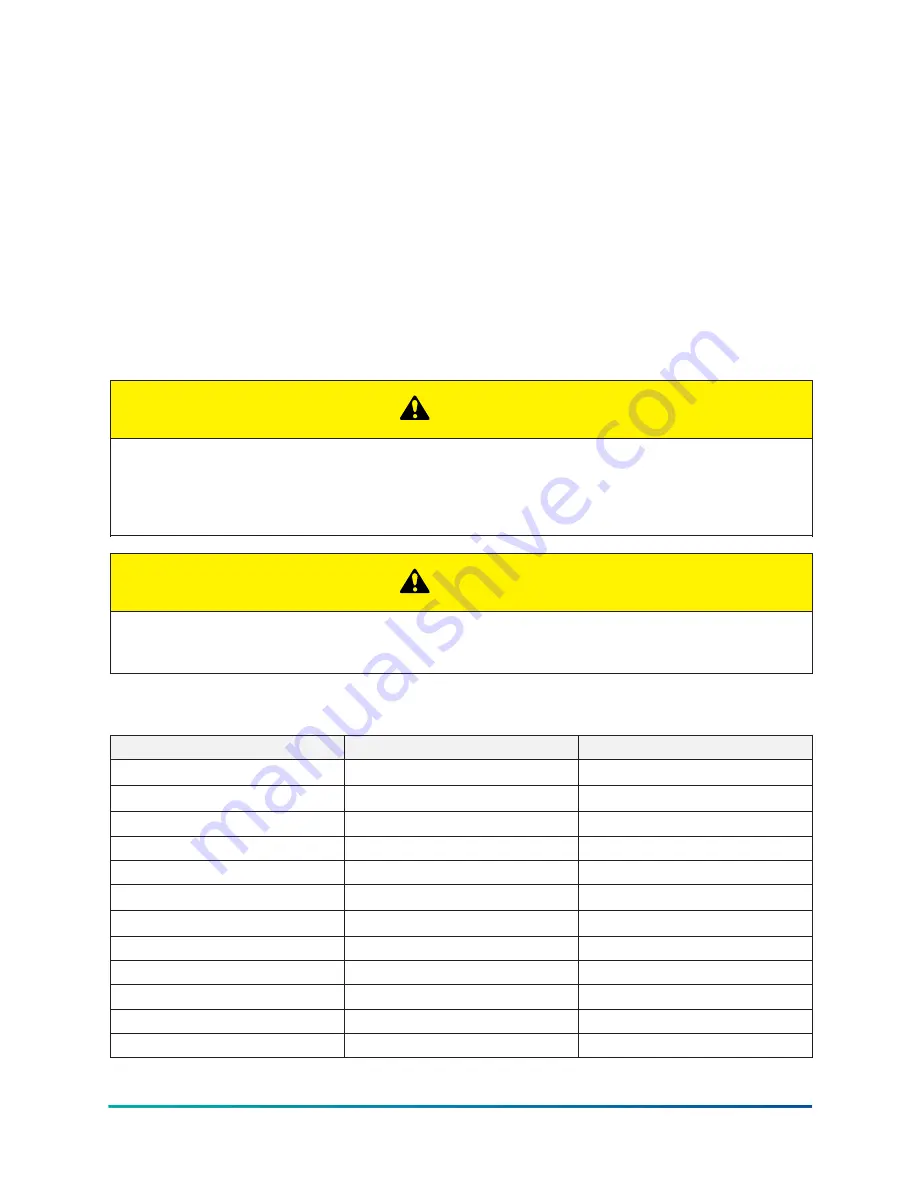

• Check the chemical specification of water in the following table for chemical consideration.

Table 13: Chemical consideration of water

Water content

Concentration

Time limit (analyze before)

Alkalinity (HCO

3

-

-)

70 to 300 ppm

Within 24 hr

Sulfate (SO

4

2-

)

˂ 70 ppm

No limit

HCO

3

-

/SO

4

2-

˃ 1.0

No limit

Electrical conductivity

10 to 500 µS/cm

No limit

pH

7.5 to 10

Within 24 hr

Ammonium (NH

4

+

)

˂ 2 ppm

Within 24 hr

Chlorides (Cl

-

)

˂ 100 ppm

No limit

Free chlorine (Cl

2

)

˂ 1 mg/l

Within 5 hr

Oxygen

˂0.02 mg/l

Within 5 hr

Hydrogen sulfide (H

2

S)

˂0.05 mg/l

No limit

Free carbon dioxide (CO

2

)

˂ 5 mg/l

No limit

Total hardness (odH)

4.0 to 8.5 mg/l

No limit

YVAM Air-Cooled Centrifugal Liquid Chiller

36