Reassembly

This section provides technical specifics for the chiller, including weights, dimensions, and torque

requirements.

Note:

The YVAM chiller is completely factory assembled and does not require any field

assembly. For occasions where field disassembly or reassembly may need to be conducted

for any reason, the following sections are intended to provide technical details for a qualified

Johnson Controls Service representative to safely complete these tasks.

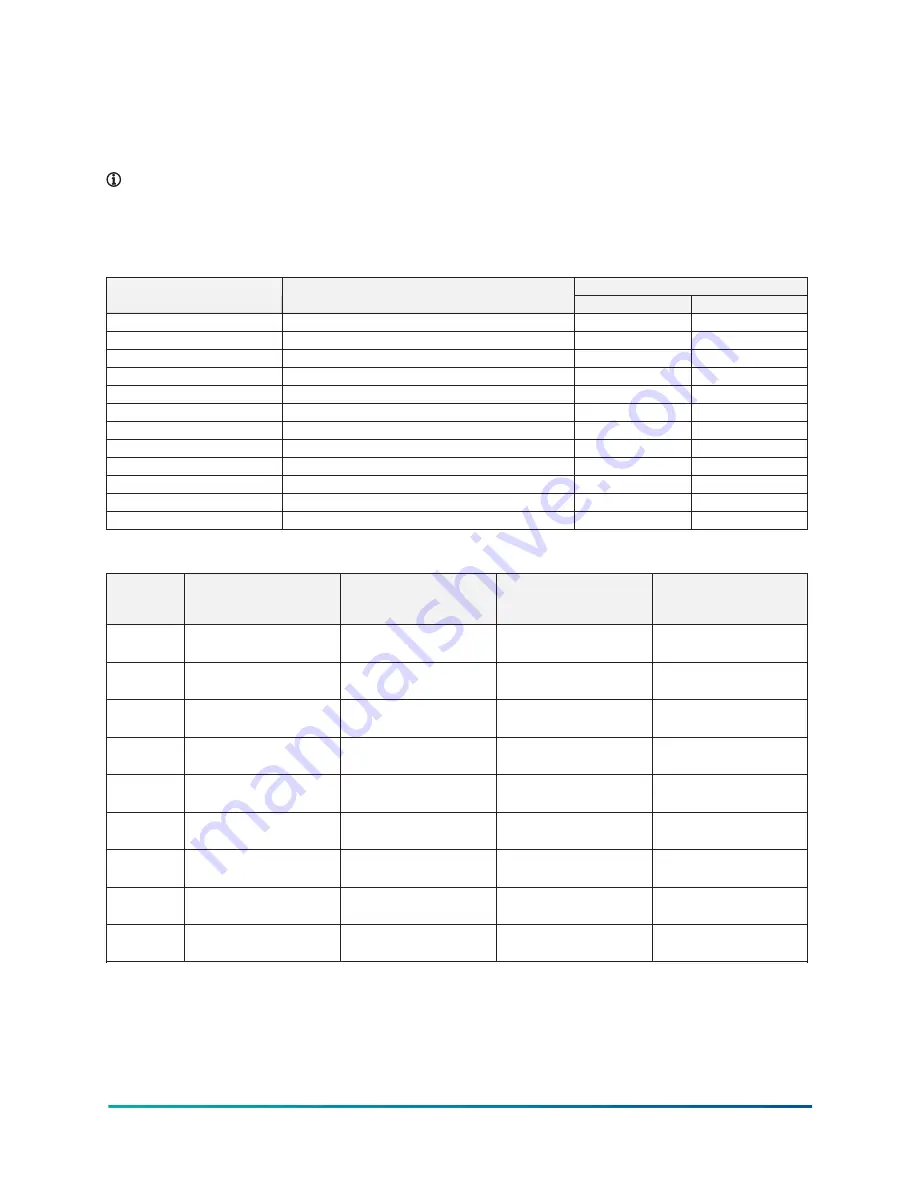

Table 14: Assembly torque metric for metric tube fittings

Torque value

Fitting size

Port thread size

lb·ft

N•m

M10

M10 x 1

17

23

M12

M12 x1.5

24

33

M14

M14 x 1.5

34

46

M16

M16 x 1.5

46

63

M18

M18 x 1.5

61

83

M22

M22 x 1.5

94

127

M27

M27 x 2

139

189

M30

M30 x 2

167

226

M33

M33 x 2

194

263

M42

M42 x 2

265

359

M48

M48 x 2

302

410

M60

M60 x 2

359

487

Table 15: Assembly torque values for SAE tube fittings

Tube size

SAE straight thread size

(O-ring part number)

SAE straight thread

torque, lb·ft

Face seal tube-side

thread size (O-ring part

number)

Face seal tube-side

torque, lb·ft

1/4 in.

7/16-20

(028-12961-001)

25

9/16-18

(028-12961-011)

18

3/8 in.

9/16-18

(028-12961-003)

35

11/16-16

(028-12961-012)

30

1/2 in.

3/4-16

(028-12961-004)

60

13/16-16

(028-12961-013)

40

5/8 in.

7/8-14

(028-12961-005)

100

1-14

(028-12961-014)

60

3/4 in.

1 1/16-12

(028-12961-006)

135

1-3/16-12

(028-12961-015)

85

1 in.

1 5/16-12

(028-12961-008)

200

1-7/16-12

(028-12961-016)

110

1 1/4 in.

1 5/8-12

(028-12961-017)

250

1-11/16-12

(028-12961-022)

140

1 1/2 in.

1 7/8-12

(028-12961-020)

305

2-12-UN2A

(028-12961-019)

180

= SAE

sightglass

2 1/4-12

(028-12961-)

225

—

—

41

YVAM Air-Cooled Centrifugal Liquid Chiller