Table 16: Chiller hardware torque values

Torque value

Location

YVAM

model

Description

P/N

SAP

Quantity

lb·ft

N•m

Mod A

021-33185-090

731065

Suction line flange at

compressor

Mod B

M24 X 3 / 90 mm long

021-35824-090

5402072

12

230

312

Mod A M20 X 2.5 / 70 mm

long

021-33184-070

731064

8

Discharge line flange at

compressor

Mod B M20 X 2.5 / 90 mm

long

021-35824-090

5402049

12

150

204

Liquid line shutoff valve inlet

flange

All

M16 X 2 / 60 mm long 021-35816-060

5399748

4

55

75

Liquid line shutoff valve outlet

flange

All

5/8 UNC 3.75 in. long 021-32310-030

555972

4

65

89

Liquid line variable orifice

butterfly valve flanges

All

5/8 UNC Stud 5.5 in.

long

021-12760-000

729652

8

45

61

Compressor mounting feet at

compressor

All

M20 X 2.5 / 60 mm

long

021-33184-060

731063

4

441

598

Compressor mounting feet at

unit base

All

3/8 UNC / 1.5 in. long 021-19305-024

564228

8

43

59

Refrigerant tubing reassembly

Use the following procedures to reassemble the chiller refrigerant piping.

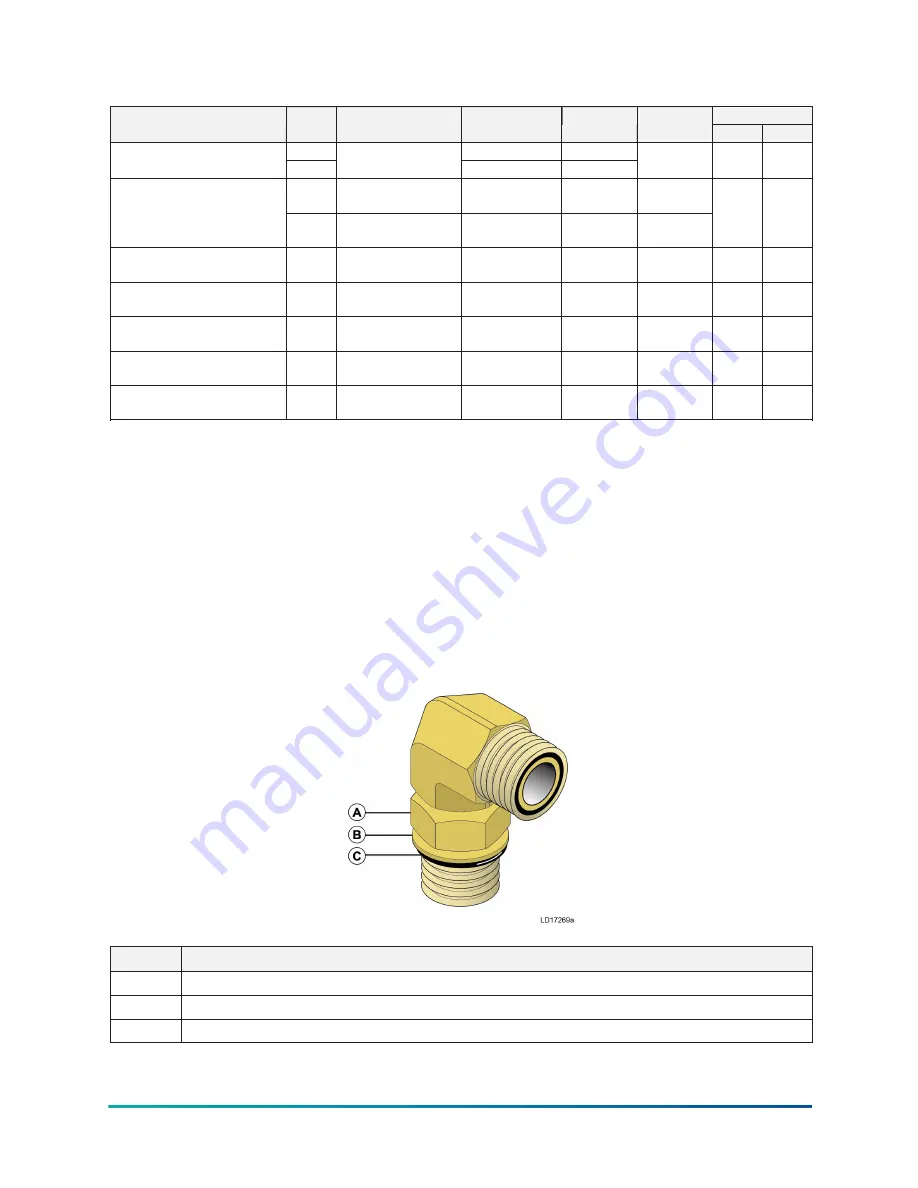

Assembly of straight thread O-ring port fittings

The male and female ends of SAE and ISO 6149 straight thread O-ring ports have UN/UNF or metric

straight threads. An elastomeric O-ring is fitted to the male end. During assembly, the O-ring is

firmly sandwiched between the angular sealing surface of the female port and the shoulder of the

male end. As a result, sealing is affected and maintained by the O-ring compression, which results

from the clamping force generated by tightening. The straight threads do not offer sealing action,

but they provide the resistance, or holding power, for service pressure.

Figure 39: Adjustable end fitting

Callout Description

A

Locknut

B

Back-up washer

C

O-ring

YVAM Air-Cooled Centrifugal Liquid Chiller

42