YZ Engineering Guide

Form: 161.01-EG1 (0618)

20

Depending on the number of units and operating characteristics of the units, loading and unloading schemes should be

designed to optimize the overall efficiency of the chiller plant. It is recommended to use an evaporator bypass piping

arrangement to bypass fluid around evaporator of any unit which has cycled off at reduced load conditions. It is also

recommended to alternate the chiller cycling order to equalize chiller starts and run hours.

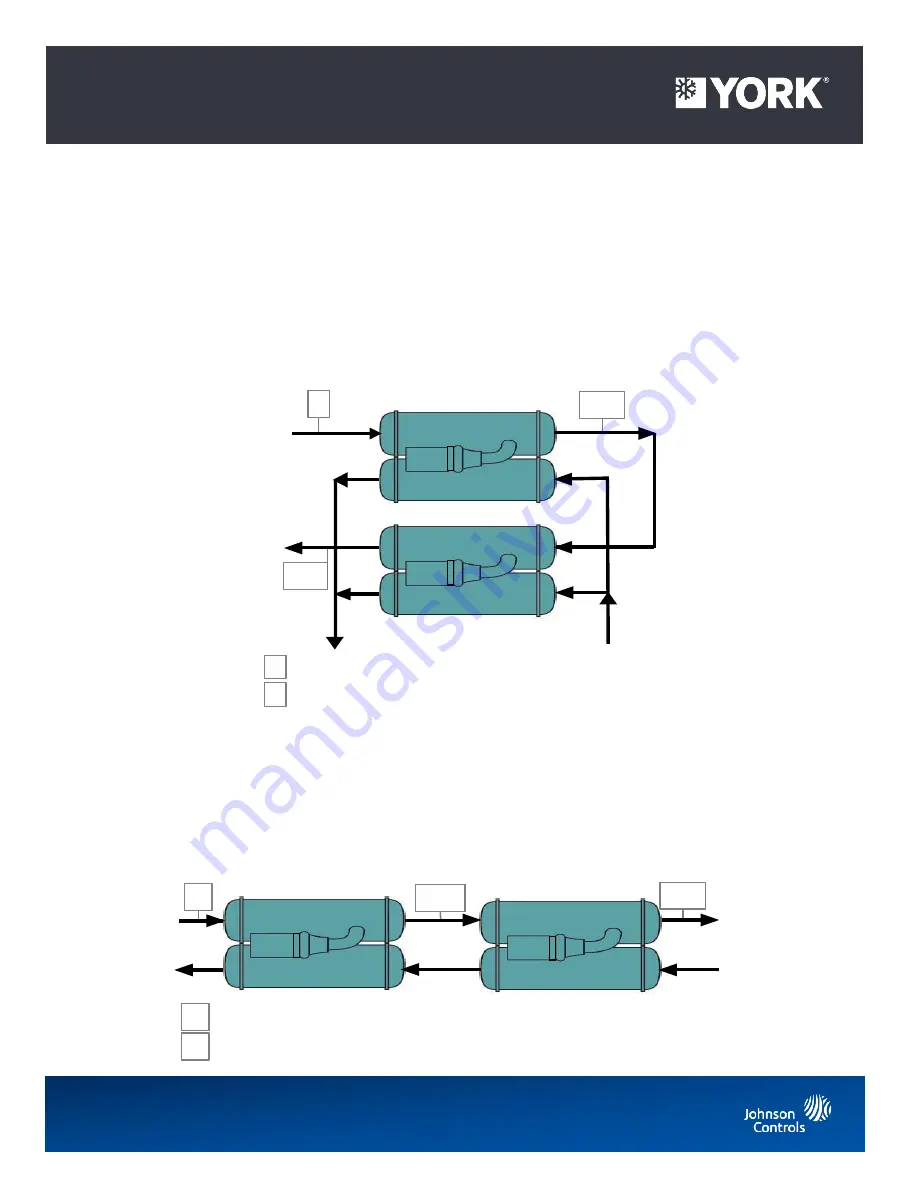

Series/Parallel Arrangement

-

Chillers may be applied in pairs with chilled water circuits connected in series and

condenser water circuits connected in parallel. All of the chilled water flows through both evaporators with each unit

handling approximately half of the total load. When the load decreases to a customer selected load value, one of the

units will be shut down by a sequence control. Since all water is flowing through the operating unit, that unit will cool the

water to the desired temperature.

Figure 2

– Series/Parallel Arrangement

Series Counter Flow Arrangement

- Chillers may be applied in pairs with chilled water circuits connected in series and

with the condenser water in series counter flow. All of the chilled water flows through both evaporators. All of the condenser

water flows through both condensers. The water ranges are split, which allows a lower temperature difference or "head"

on each chiller, than multiple units in parallel. For equal chillers, the machine at the higher temperature level will typically

provide slightly more than half the capacity. The compressor on each chiller is often matched, such that the high

temperature machine can operate at the low temperature conditions when one unit is cycled off at part load (as compared

to series-parallel chillers which are typically not identical).

Figure 3

– Series Evaporators (Evap.) Series-Counter Flow Condensers (Cond.)

Cond. 1

Evap. 1

Cond. 2

Evap. 2

S1

S2

T

S

- Temperature Sensor for Chiller Capacity Control

- Thermostat for Chiller Capacity Control

T

Cond.

1

Evap. 1

Cond. 2

Evap. 2

T

S1

S2

T

S

- Temperature Sensor for Chiller Capacity Control

- Thermostat for Chiller Capacity Control