-2-

■

EPDT

-

183b

■

Chart 2 Dimensions & Weight

(mm)

H

2

Weight (kg)

Nominal

Size

L

H

1

SU-50

・

50H

SU-50S

ds

ls

d

do

SU-50

・

50H

SU-50S

50A

243

166

88

140

64.5

108

R1/4

R3/4

13.0

13.0

65A

254

166

88

140

64.5

108

R1/4

R3/4

15.0

15.0

80A

300

204

98

163

77

140

R3/8

R1

20.0

20.0

100A

315

230

103

166.5

90

160

R3/8

R1

29.0

28.0

150A

455

385

137

211

140

270

R3/8

R1-1/2

73.5

72.0

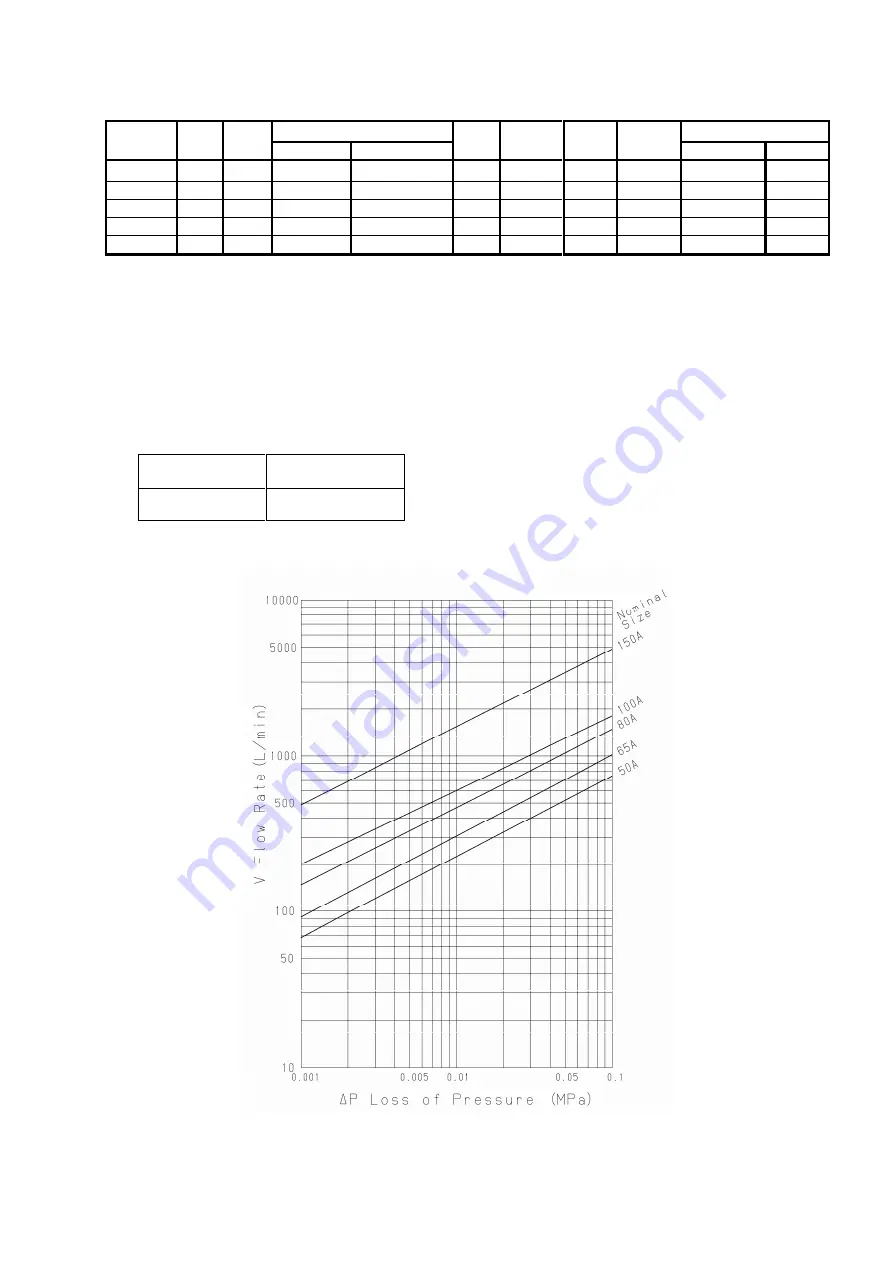

3.

Selection of nominal size

The nominal size of the strainer should be the same as that for the piping. (Nominal size of piping

=

Nominal size of strainer). Please note that if the nominal size of the strainer is smaller than that for the

piping, the pressure loss of the strainer may grow, resulting in failure to maintain the required pressure

at the inlet of the strainer.

(

See Fig.3: Loss of Pressure.

)

The Japan Industrial Standards (JIS) designates the standard flow velocity for piping by type and

features of the fluid and pipe size. Please refer to this in selecting the appropriate nominal size of the

strainer.

Chart 3 Standard flow velocity by fluid

Fluid

Standard flow speed

Water & Oil

2 m/s (2

~

4)

※

The standard flow velocity in this chart have been calculated based on the requirements in JIS F

7101(Pipes of Ship’s Machinery: Standard Velocity of Flow, 1999 ).

Screen:

φ

6-14.2strain pipes /cm

2

Fig. 3 Loss of Pressure

(

Fluid

:

Water

)