-4-

■

EPDT

-

183b

■

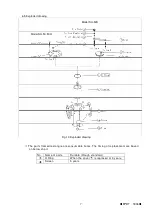

Chart 4 Dimensions required for removal of the screen

Nominal Size

A

(mm)

B

(mm)

50, 65A

300

180

80A

350

210

100A

400

220

150A

600

280

5. Operation

5.1 Warning and caution upon operation

Warning

(

1

)

Please make sure that there is no danger at the pipe end before pouring the fluid.

※

You may get scalded in case hot fluid spouts out.

※

Physical damage may occur from fluid outflow.

Caution

(

1

)

This product should be used only when the maximum pressure loss is 0.1MPa or less. Please

also clean the screen regularly.

※

Neglect can result in damage of the screen.

6. Maintenance

6.1 Troubleshooting

Condition of

failure

Causes

Measures and treatment

Fluid does not flow.

1. Screen

④

is clogged.

2. The stop valves at either end of the

strainer are closed.

1. Disassemble the strainer and clean screen

④

.

2. Open the stop valve(s).

Loss of pressure is

great.

1. Screen

④

is clogged.

2. The pressure gauge is out of order.

3. The nominal size is too small for

the actual flow volume.

1. Disassemble the strainer and clean screen

④

.

2. Exchange the pressure gauge.

3. Use a strainer with a larger nominal size,.

(

Refer to Fig.

3

: Loss of Pressure

)

Alien matter is not

removed.

1.Screen

④

is damaged.

1.Disassemble the strainer and exchange

screen

④

. In case quick valves are installed

at either end of the strainer, do not open

them immediately since this may result in

damage of the water hammer.

Cover

②

cannot

be removed upon

exchange of

screen.

1.The inside of the product is

vacuum.

2.Cover

②

and body

①

are stuck

together.

1.Break the vacuum inside the pipe and

remove cover

②

.

2. Refer to 6.3 Removal of the screen.

Outer leakage

occurs.

1.O-ring

⑧

is damaged.

2.Cover

②

is not assembled

properly.

1. Install a new O-ring.

2.Assemble properly by referring to 6.4

Assembly after disassembly.

6.2 Warning and caution upon inspection

Warning

(

1

)

Remove all pressure within the product, piping, and equipment before disassembly and

inspection.

In case of hot fluid, cool down the product body so you can touch it with your bare hand before

disassembly and inspection.

※

Residual pressure in the product or piping can result in injuries or scalding.