-6-

■

EPDT

-

183b

■

6.4 Assembly after disassembly

(1) Clean body

①

and the portions on cover

②

that come in contact with the O-ring.

(2) Assemble screen

④

onto the cleaned body.

(3) Apply silicone grease onto a new O-ring

⑧

and assemble it onto the slot on the cover

②

,

then assemble the cover onto the body.

(4-1) For Model SU-50

・

50H, tighten bolts

⑦

.

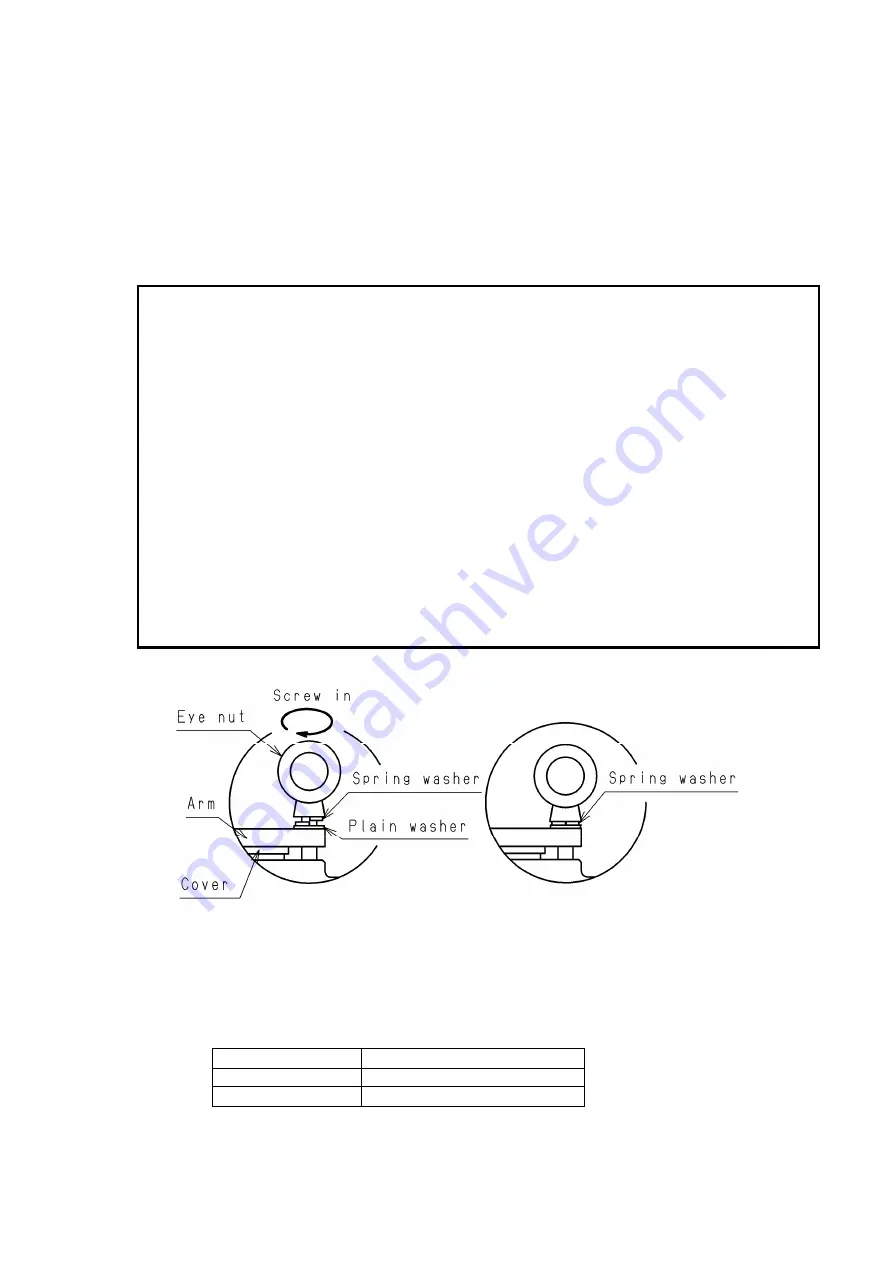

(4-2) For Models SU-50S, return arm

③

to the position of stud bolts

⑤

, then tighten the

eye nuts

⑥

.(Please confirm that the plain washers

⑫

and spring washers

⑬

have

been fit onto the arm before this.)

Cautions

(1) Clean body

①

and the portions on cover

②

that come in contact with the O-ring

⑧

.

※

Insufficient cleaning can result in outer leakages.

(2) Please take care not to damage the O-ring

⑧

upon assembly onto the cover

②

.

※

Damage can result in outer leakages.

(3) Use a new O-ring

⑧

, and apply silicone grease onto it.

※

A used O-ring may break and result in outer leakages. It may also become impossible to

remove the cover.

(4) In case screen

④

is deformed or damaged, exchange it to a new one.

※

The product will not function with a deformed or damaged screen.

(5) Securely assemble each part upon assembly.

※

Insecure assembly may result in deformation or damage to the parts.

(6) Upon assembly of Models SU-50S, confirm that the plain washers

⑫

and spring washers

⑬

have been fit onto the arm. (See Fig. 8.)

※

Neglect can cause deformation of the cover and arm resulting in outer leakages or other

damages.

(7) Upon assembly, make sure that bolts

⑦

and eye nuts

⑥

are tightened evenly on either side.

Please be careful not to tighten the eye nuts too tightly.

(

Refer to the torque values in Chart 3.

)

※

Neglect can cause deformation of the cover and arm resulting in outer leakages or other

damages.

Fig.9 Position for parts on Models SU-50S

※

Tighten the eye nuts till they come in close contact with the spring washers.

(Please be careful not to tighten the eye nuts too tightly.)

Chart 5 Tightening torque for the eye nuts (recommended values)

Nominal size

Tightening torque

(

N

・

m

)

50, 65A

20

80

~

150A

30