‐

2

‐

■

EPDT-002g

■

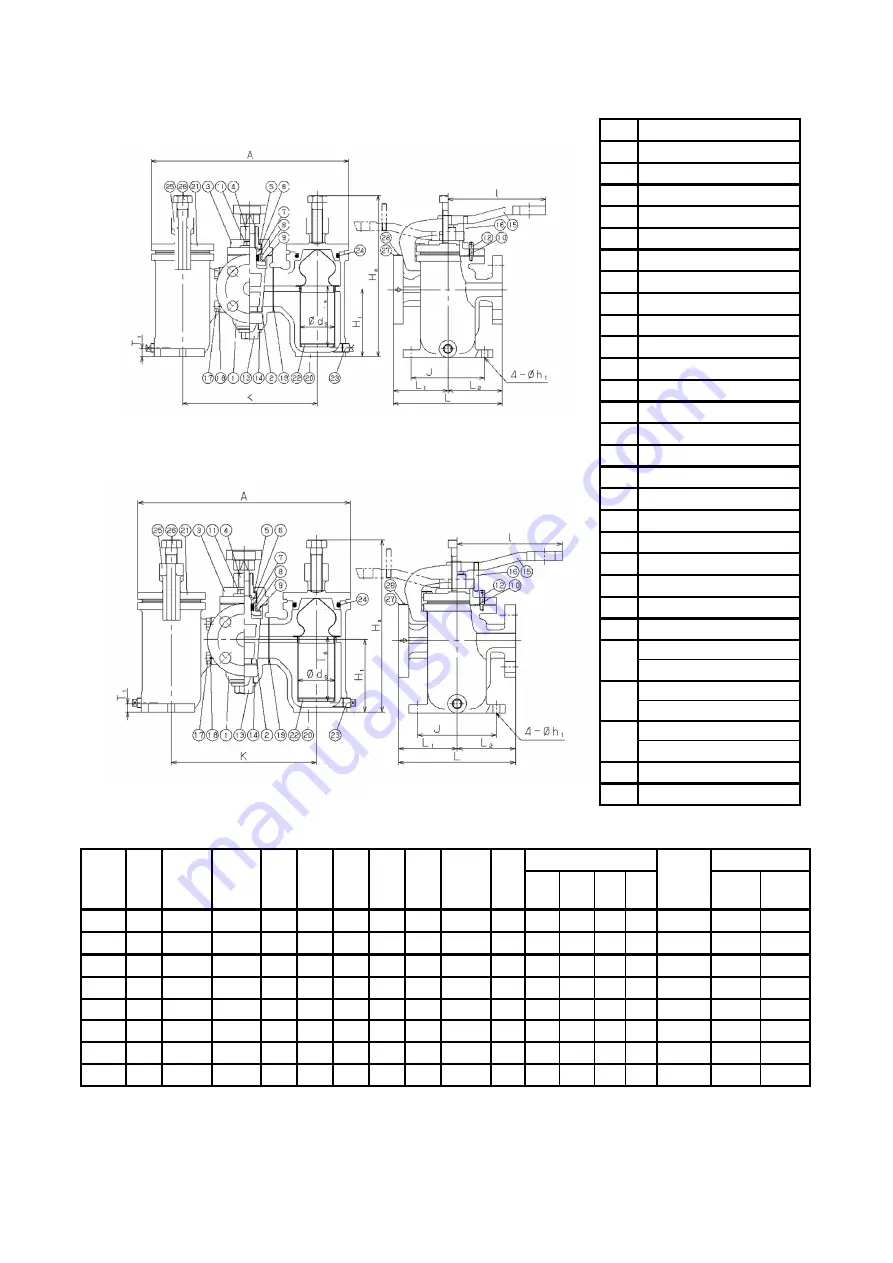

2.2 Structure, Dimensions and Weights

●

SW-10

●

SW-10S

No.

Parts name

1

Body

2

Cock

3

Gland cover

4

Adjusting screw

5

Washer

6

Washer of Packing

7

U-packing

8

Packing Case

9

Gasket

10

Gasket

11

Bolt

12

Pin

13

Cap

14

Gasket

15

Handle

16

Stopper

17

Bolt

18

Spring Lock washer

19

Gasket

20

Screen case

21

Cover

22

Screen

23

Plug

24

Gasket (SW-10)

O-Ring (SW-10S)

25

Stud Bolt (SW-10)

Arm (SW-10S)

26

Nut (SW-10)

Bolt (SW-10S)

27

Plate

28

Driving screw

Size

L

L

1

L

2

H

1

H

Ha

A

l

ds

ls

Anchor Base

Plug

Weight(kg)

J

K

h

1

T

1

SW-10

SW-

10S

20A 200 100

100

126 280 292 363 180

64.5 108 135 248 12 14 R 3/4

23.9

26.7

25A 200 100

100

126 280 292 363 180

64.5 108 135 248 12 14 R 3/4

25.1

27.9

32A 205 102.5 102.5 126 280 292 363 180

64.5 108 135 248 12 14 R 3/4

26.1

28.9

40A 245 122.5 122.5 134 306 316 390 180

64.5 120 135 275 12 14 R 3/4

34.0

36.8

50A 245 122.5 122.5 134 306 316 390 180

64.5 120 135 275 12 14 R 3/4

35.9

38.7

65A 285 130

155

155 356 345 450 240

77

140 160 311 15 20 R 3/4

52.5

54.6

80A 285 130

155

155 356 345 450 240

77

140 160 311 15 20 R 3/4

53.0

55.1

100A 385 175

210

230 482 509 644 340 120

210 225 430 19 20

R 1

117.0 124.3

*Size of plug for stainless steel products are all R3/4.

Fig.1 Structure, dimensions and weights