‐

7

‐

■

EPDT-002g

■

7. Assembly after disassembly

Model SW-10

Caution

1. Clean up the seating surface of gasket on the body and cover.

*Insufficient cleaning can result in outer leakage and injuries or burns.

2. Replace to new gasket upon assembly.

*Using old gasket may cause leakage.

1. Clean the gasket contacting surface of the screen case and cover. Attach the new gasket to the cover.

2. Install cleaned screen to screen case and attach cover, then tighten the hexagon nut.

Model SW-10S

Caution

1. Clean the contacting surface of the screen case and cover. Make sure that O-ring

is attached properly.

*If the O-ring is not installed properly, O-ring may be damaged and can be result in

outer leakage.

2. In case O-ring is damaged or deteriorated, replace to new O-ring and apply grease

on it.

*There is a possibility of leakage in case O-ring is damaged or deteriorated.

1. Clean the O-ring contact surface of the screen case and cover, and install the O-ring to the groove of the

cover. At this time, attach the O-ring so that it does not protrude from the O-ring groove.

2. Install cleaned screen into the screen case and attach to the cover. Tighten the hexagon bolt.

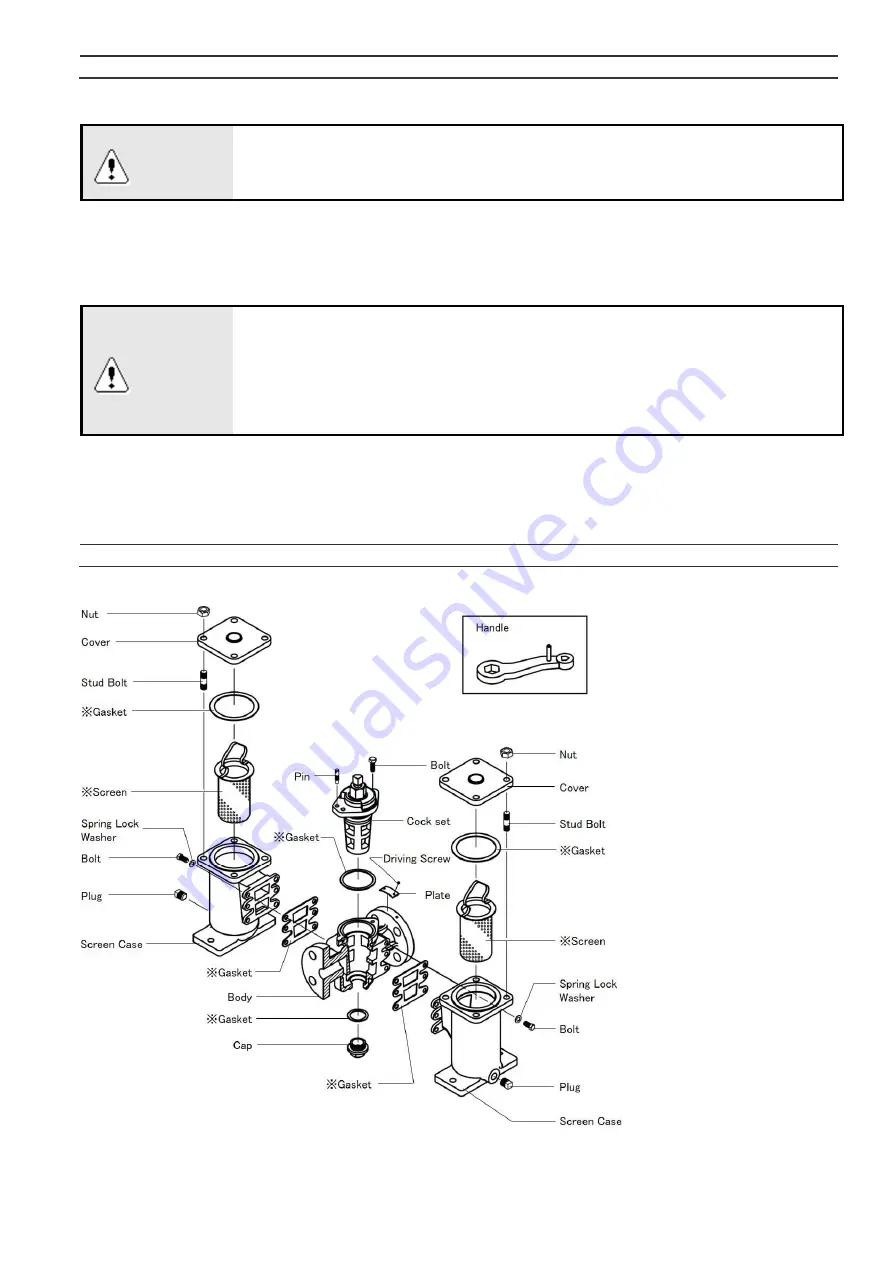

8. Exploded view

Model SW-10 (The structure of SW-10S is different)

※

Are consumable parts