6

■

EPDT-049a

■

8. Disassembly, Cleaning and Reassembly

Excessive amount of foreign substances inside the product reduces filtration area and hampers fluid

flow. If the product is kept for such condition, the screen is damaged and results in adverse effect on

the piping system due to excessive pressure difference.

8.1 Precaution for disassembly and inspection

Warning

1. Completely discharge the pressure inside of the product, piping and equipment prior to disassembly and

inspection. When fluid is hot, cool down the product.

* Failure to follow this notice may result in scalds or injury due to the residual pressure.

2. After checking the pressure gauge to make certain there is no pressure inside the body [1], remove the

cover [2] and screen [3]. Clean up the screen [3] by compressed air or water.

8.2 Precaution for reassembly

Caution

1. Clean the gasket contact surfaces of both the body and the cover.

* Improper cleaning may cause fluid leakage at the gasket resulting in scalds or injury.

2. When reassembling, replace the gasket with a new one.

* Failure to follow this notice may result in fluid leakage.

3. After cleaning the gasket contact surfaces of both the body [1] and the cover [2], attach a new gasket [4]

to the cover [2], and then attach the cleaned screen [3] into the groove on the cover [2]. Install the

assembly (cover [2], gasket [4], and screen [3]) to the body [1].

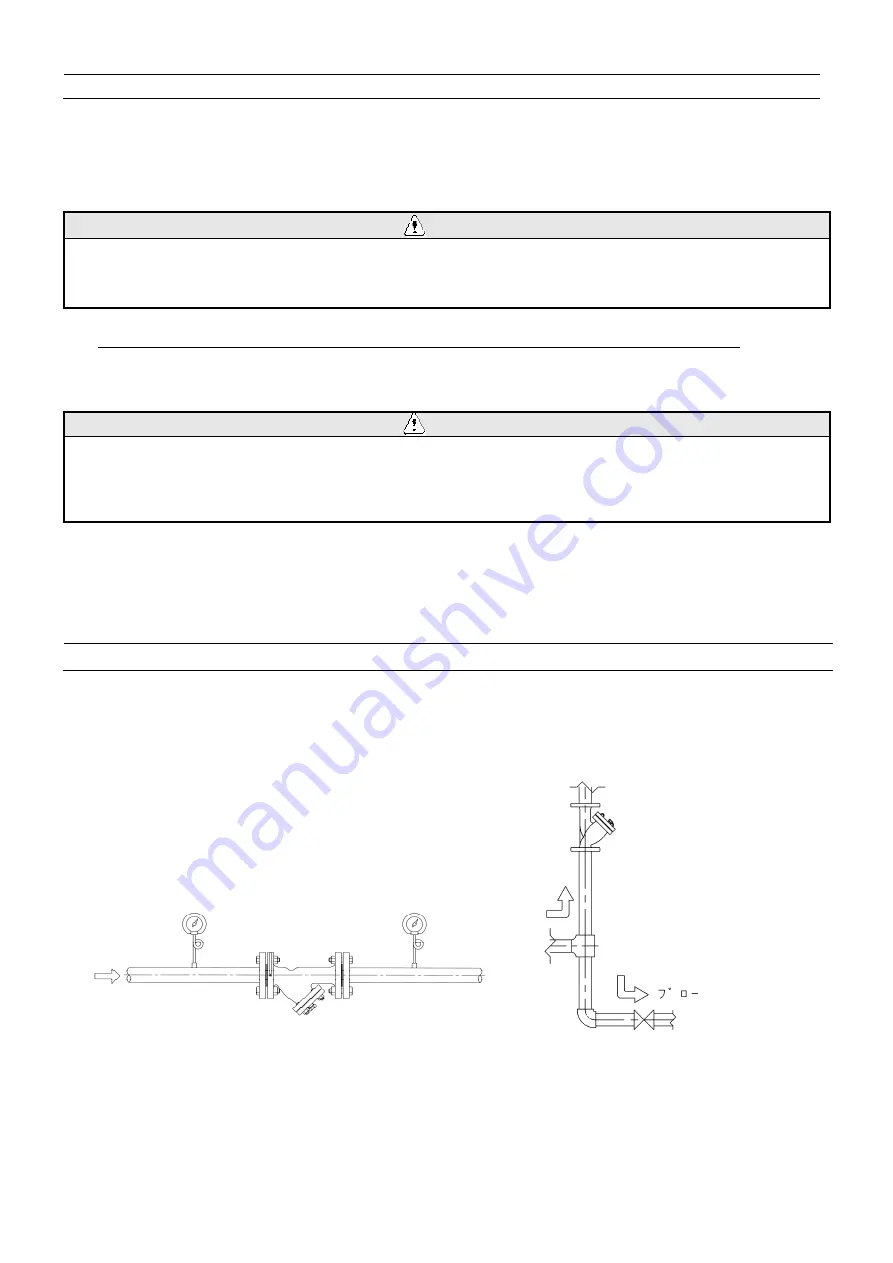

9. Piping Example

Fig. 1

Fig. 2