SMART POSITIONER

TMP-3000

PRODUCT MANUAL

Ver. 1.03

21

6.

Auto Calibration and How to Operate

6.1

Warning

This operation will move the valve and actuator so that the valve must be

disconnected from the entire system before auto-calibration to ensure that the entire

process is not affected.

6.2

Button Description

There are total of four buttons in the positioner. You can use it to implement various

functions.

Fig. 6-1: <UP> & <DOWN >: Used to change parameter values in menu when moving to other menu

<ENTER>:

Used to enter the main menu or submenu, to save parameter values

<ESC>:

Used to return to the previous menu one level from the current menu

6.3

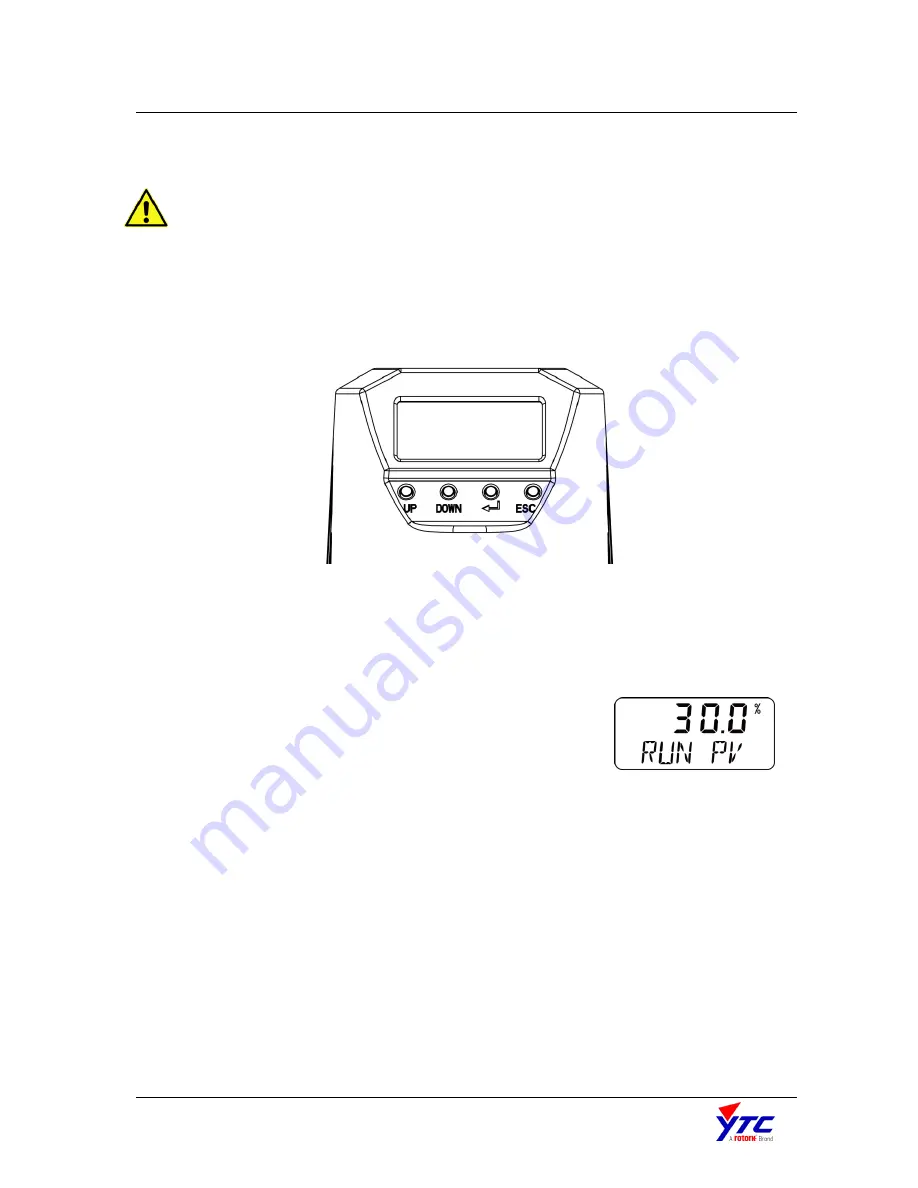

Run Mode (RUN)

When the current is input to the positioner, the RUN mode is

displayed on the LCD window after about 0.5 second as

shown in the figure. "RUN" indicates that the positioner is

adjusting the valve stroke according to the current signal (normally 4 ~ 20mA DC)

received from the outside. The lower part of the figure, "PV", is an abbreviation of the

valve's process value, and the upper "30.0%" indicates that the current valve opening is

30%.

There are 5 types to display in "RUN" mode as follows.

1.

RUN PV :

Process Value

–

Valve Stoke %

2.

RUN SV (%) :

Set Value

–

Input Signal, 0~100%

3.

RUN SV (mA) :

Set Value

–

Input Signal, 4~20mA, 0~20mA, 0~5V, 0~10V

4.

RUN MV :

Manipulate Value

–

Torque motor control value, Digit

5.

RUN ERR :

Error

–

Difference between SV and PV, %

To change the RUN PV to another RUN mode, hold down the <ESC> button and press the

<UP> or <DOWN> button to display the above five modes sequentially each time you press.