13

YT-3300/3301 series

3. Installation

3.1 Safety

When installing a positioner, please ensure to read and follow safety instructions.

Any input or supply pressures to valve, actuator, and / or to other related devices must

be turned off.

Use bypass valve or other supportive equipment to avoid entire system “shut down”.

Ensure there is no remaining pressure in the actuator.

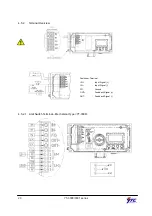

3.2 YT-3300/3301L

Installation

YT-3300/3301L should be installed on linear motion valves such as globe or gate type which

uses spring return type diaphragm or piston actuators. Before proceeding with the

installation, ensure following components are available.

Positioner

unit

Feedback lever and lever spring

Flange nut (bottom side of YT-3300/3301L)

4 pcs x hexagonal headed bolts (M8 x 1.25P)

4 pcs x M8 plate washer

3.2.1 Installation

Steps

1. Proper bracket must be made in order to adapt the positioner on the actuator yoke.

Please consider following important points when a bracket is being designed.

Positioner’s feedback lever must be parallel to the ground at 50% of the valve stroke.

Feedback lever connection with the pin of the actuator clamp should be installed in

such a way that the valve stroke length coincides with the corresponding figure in

“mm” marked on the feedback lever. Improper setting may cause poor linearity and

may create unnecessary hunting during the operation.

2. Assemble the positioner with the bracket made in previous step by fastening the bolts.

Please refer to the backside of the positioner for size of the bolts. The standard bolt

size is M8 x 1.25P. Please contact Young Tech Co., Ltd for other bolt sizes.

YT-3300L

YT-3301L