41

Chapter4

System Maintenance

To ensure normal use of laser cutting machine, it is necessary to perform routine care and maintenance on

equipment. Since the whole machine tool is assembled with high-precision parts, be careful in the routine

maintenance process, operate in strict accordance with the rules of each part, and perform maintenance by

dedicated personnel to avoid damage to components.

4.1

Mechanical maintenance

Mechanical maintenance mainly includes the maintenance of: guide rail, lead screw, synchronous belt,

synchronous belt wheel, screw and coupling. It is a must to the followings well done for maintenance:

After completing use every day, cleaning all parts of the equipment.

Oil sliding mechanism such as guide rail and lead screw with lubricant.

Make irregular check on the equipment to mainly check if there is poor contact of the joints. In case of

abnormality, timely treatment is needed to avoid causing serious problems.

4.1.1

Synchronous belt, synchronous belt wheel

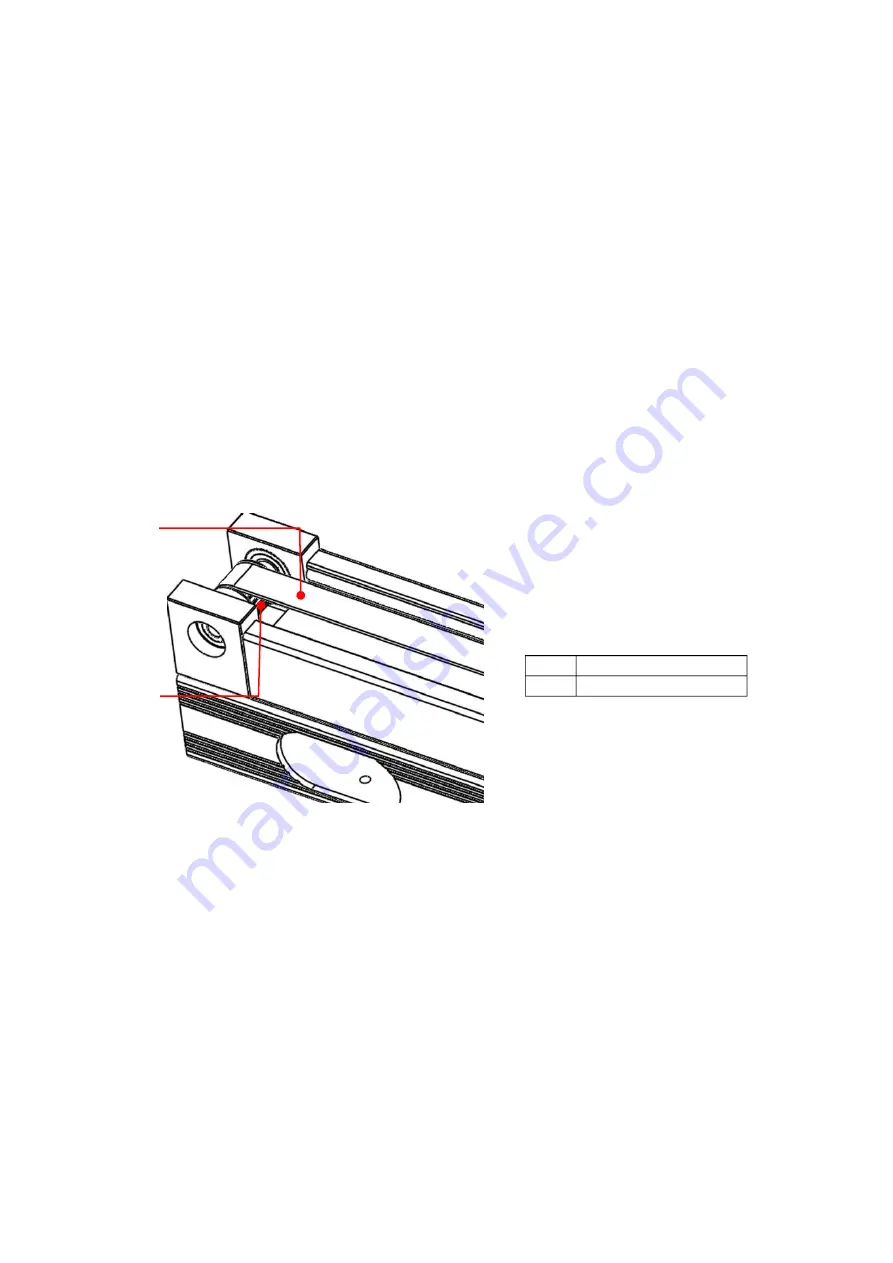

Figure 4-1

Timing Belt and Pulley Diagram

Synchronous belt and synchronous belt wheel are the main mechanical parts of the equipment, and they

control movement track of the laser head. After movement for a certain period, the synchronous belt will

frequently be longer and loose in a small size. That will lower the accuracy and sensibility of the laser head,

Therefore, timely adjusting the transmission belt is needed.

Adjustment method: Adjustment of X direction and Y direction synchronous belt should achieve a proper

tension of it; adjustment of drive motor synchronous belt is to achieve that when pressing middle part of the

synchronous belt, the sinking level is 3% to 5% of the central distance between the belt wheel at the two ends.

Attention:

If to adjust the transmission belt too tight, the belt is not only easily made distortion but also cause more

severe abrasion of the bearing; if too loose, transmission accuracy and sensibility will be lowered. Therefore, you

①

Synchronous belt

②

Synchronous belt wheel

①

②