37

Replacing Wheel and Motor

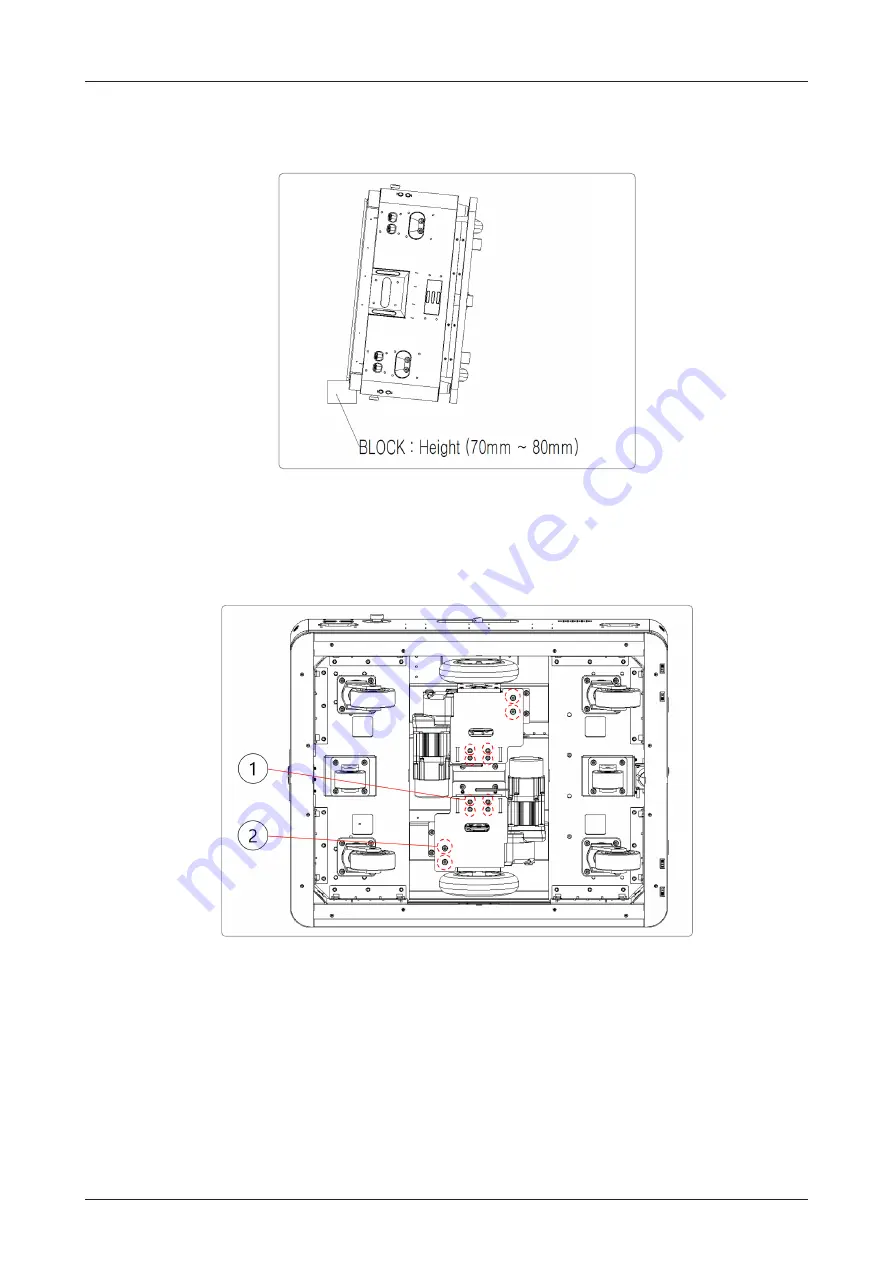

1. Disassemble ④⑤⑥⑦⑧⑨⑩⑪ connectors of a ①motor drive assembly.

2. Bring a block (height 70 mm ~ 80 mm) that can withstand the weight of the robot. Place the side of

the robot on the block carefully.

Fig. 33: Motor Drive Assy Replacement (2)

3. Remove the SCREW from the motor drive assembly.

4. After replacing the motor drive assembly, apply LOCTITE 242 to the SCREW and then tighten it.

5. Connect the connectors in the reverse order of assembly.

Fig. 34: Motor Drive Assy Replacement (3)