INStALLAtIoN

VERtICAL fLUE:

1. Adjustment weight must be in RIGHT HAND SLOT

(marked "V") in bracket on gate.

2. The arrow on flap at bottom of gate must line up with letter

"V" on lower right part of gate. If it does not, remove flap,

turn over and snap onto gate again.

Flap can be removed by inserting small screwdriver at the back

side of the gate between the gate and the flap, then pulling

downward on flap.

HoRIZoNtAL fLUE:

1. Adjustment weight must be in LEFT HAND SLOT

(marked "H") in bracket on gate.

2. The arrow on flap at bottom of gate must line up with letter

"H" on lower left part of gate. If it does not, remove flap,

turn over and snap onto gate again.

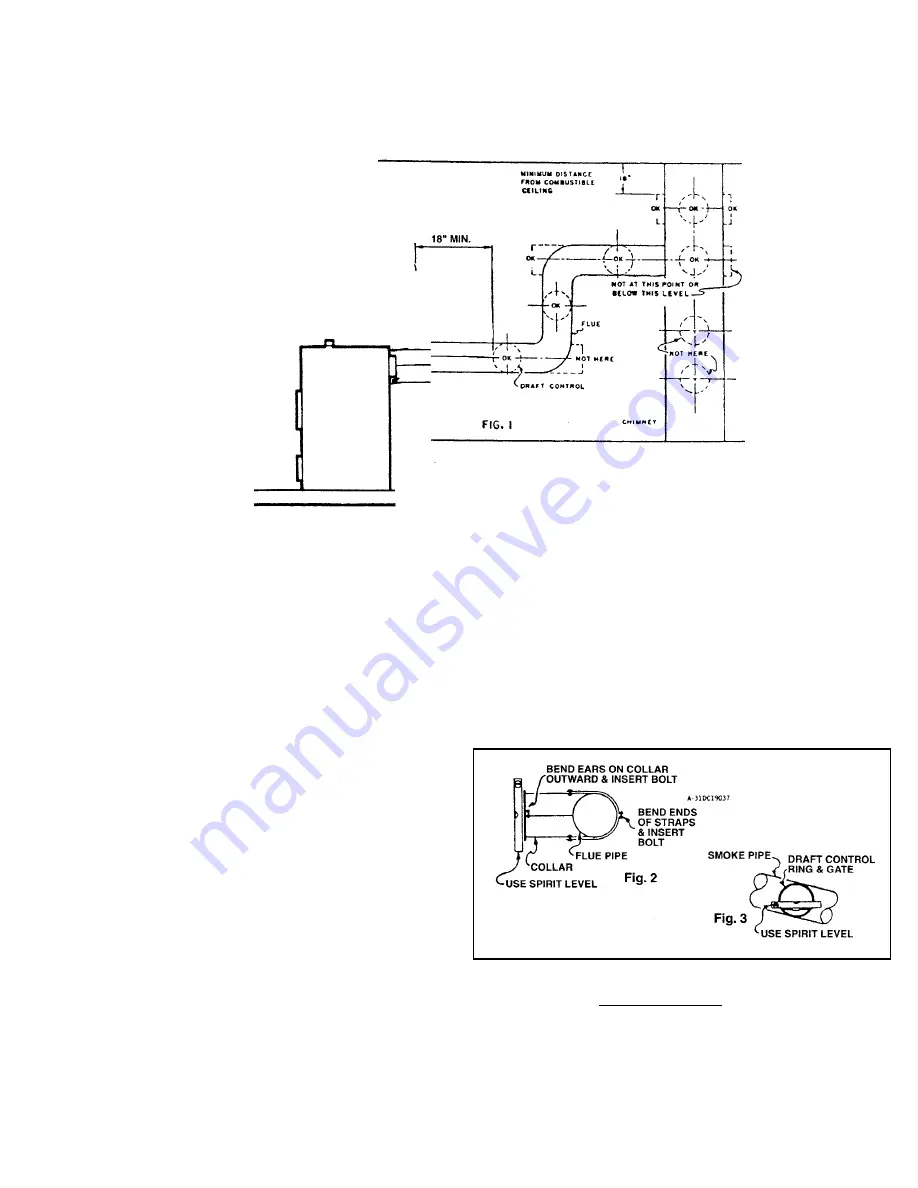

Bend outward the two ears at the front corners of collar and insert

clamping screw. Bolt the remainder of the collar together. See

Figure 2. Hold the collar against the flue in the EXACT position

and mark the outline of the collar on the flue. Cut a hole in the flue

about half an inch smaller than the marks.

Then cut a series of short slits (about 3/8" or 1/2" deep) around

the edges of the opening. After the collar is strapped on the flue

the cut edges can be bent outward into the collar and thus make

a better joint. WHEN FINISHED, THE OPENING INTO THE FLUE

MUST BE EQUAL IN SIZE TO THE COLLAR OF THE DRAFT

CONTROL. If flue pipe is made of material too heavy to bend out

into the collar, the opening into the flue must be within 1/4" of the

same diameter as the collar.

Strap the collar to the flue pipe and place the draft control into the

collar, fastening it there by tightening the clamping screw in the

collar.

Use a spirit level to make sure that the control does not lean for -

ward or backward but instead is plumb in both directions, regard-

less of whether the flue is horizontal, vertical or sloping.

INItIAL SEttING of BARoMEtRIC CoNtRoL

Set the control at a maximum of .03 or as low a draft as will

give good combustion and meet the requirements for heat. Turn

adjustment weight counter-clockwise to loosen, then slide in slot

to proper position and tighten. Bracket is marked 2, 4, 6, and 8,

which indicates draft settings of .02, .04, etc. (These are drafts in

flue adjacent to control, not over-fire drafts.) A monometer must be

used to accurately adjust flue draft.

INStRUCtIoNS foR INStALLING

fIELd R-C

BARoMEtRIC dRAft CoNtRoLS

CHOOSING THE LOCATION

Do not attach draft control to top or bottom of flue

pipe, nor in a room separated from appliance.

Best location is as close to appliances as possible.

10

Summary of Contents for SUPER JACK SJ125

Page 2: ......

Page 4: ......

Page 7: ......

Page 13: ...13...

Page 19: ...19...

Page 20: ...20 BIG JACK BJ90 PARTS LIST...

Page 21: ...21...

Page 22: ...22 SUPER JACK SJ125 PARTS LIST...

Page 23: ......