10

• Use only copper wire for the line voltage power supply

to this unit. Use proper code agency listed conduit and

a conduit connector for connecting the supply wires to

the unit. Aluminum supply wire may be used if a heater

kit is installed.

• Provide power supply for the unit in accordance with the

unit wiring diagram, and the unit rating plate. Use UL

listed conduit and conduit connectors for connecting the

supply wires to the unit and for proper grounding. Field

supplied bushings for the power supply cables must be

added to support and protect the power supply cables.

• If replacing any of the original wires supplied with the

unit, the replacement wire must be copper wire consisting

of the same gauge and temperature rating.

• Circuit breakers installed in the B5BV series electric

furnace are for short-circuit protection of the internal

wiring and to serve as a unit disconnect. They do not

provide over-current protection of the supply wiring.

Overcurrent protection must be provided at the branch

circuit distribution panel and sized as shown on the unit

rating label and according to applicable local codes. See

the unit rating plate and Table 4 (page 15) for maximum

circuit ampacity and maximum overcurrent protection

limits.

• All 208/230 Volt units are shipped from the factory wired

for 240 volt operation. For 208V operation, remove the

lead from the transformer terminal marked 240V and

connect it to the terminal marked 208V.

Single Circuit Adaptor Kit

If a single circuit adaptor kit is used, it may need to be re-

configured for some applications. Remove the single circuit

adaptor kit cover and verify that the lugs are configured

correctly for the application. If the lugs are not configured

for the application, refer to the instructions included with

the kit and modify the configuration.

Install the single circuit adaptor kit (if used) in the line

side (“on” end) of the circuit breakers. Tighten the lugs

securely (45 in-lbs recommended).

Connect the supply

wiring to the circuit breakers, single circuit adaptor kit, or

terminal block. Tighten the lugs securely.

Dual Supply Circuits

When using dual supply circuits verify that the supply

sized for circuit “A” is connected to the circuit breaker

that is connected to the top element assembly.

Replace

metal circuit breaker line cover. Refer to Figure 15 (page

20) for thermostat wiring examples.

Control Board

The control board in the electric furnace controls the

timing sequence of the elements. The board is equipped

with a 3 second blower ON delay and a 15 second blower

OFF delay in heating and a 40 second blower OFF delay

in cooling.

Twinning

Electric furnaces are not supplied with a built in twinning

capability. To connect two electric furnaces to a common

single stage AC condensing unit or heat pump, a twinning

kit is available for field installation.

Please follow the

instructions supplied with the kit.

NOTE:

Variable speed electric furnaces cannot be twinned.

Thermostat Connections

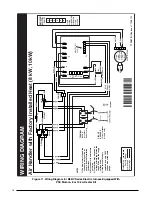

• Thermostat connections shall be in accordance with the

instructions supplied with the thermostat and the indoor

equipment. The low voltage wires must be properly

connected to the units low voltage terminal block.

• A single stage thermostat is used with this equipment

and must operate in conjunction with any installed

accessories. Typical AC and electric furnace hookups

are shown in Figure 15 (page 20).

CAUTION:

Isolation must be maintained from the external

Class 2 output of any transformer in a cooling

circuit. Use a thermostat with isolating contacts

to prevent inter-connection of Class 2 outputs.

• Where local codes require that the thermostat wiring

must be routed through a conduit or raceway, splices

can be made inside the unit; however, all wiring must

be NEC Class 1 and must be separated from incoming

power leads.

• The thermostat should be mounted about 5 feet above

the floor on an inside wall. DO NOT install the thermostat

on an outside wall or any other location where its

operation may be adversely affected by radiant heat from

fireplaces, sunlight, or lighting fixtures, and convective

heat from warm air registers or electrical appliances.

Refer to the thermostat manufacturer’s instruction sheet

for detailed mounting and installation information.

• Install the grommet, which is packed with the unit, in

the hole for low-voltage wires. Connect the low-voltage

wiring to the thermostat and the outdoor unit and the

appropriate screw terminal located on the control board.

NOTE:

When the low voltage wires are positioned in

this grommet, the grommet will prevent chafing and/or

shorting of the low voltage leads.

Grounding

WARNING:

The unit cabinet must have an uninterrupted

or unbroken electrical ground to minimize

personal injury if an electrical fault should occur.

Do not use gas piping as an electrical ground!

This unit must be electrically grounded in accordance

with local codes or, in the absence of local codes, with

the National Electrical Code (ANSI/NFPA 70) or the CSA

C22.1 Electrical Code. Use the grounding lug provided in

the control box for grounding the unit.