16

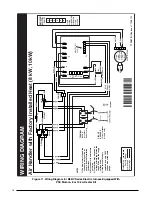

Figure 11. Wiring Diagram for B5BV Series Electric furnace Equipped With

PSC Motor & 8 or 10 kw heater Kit

BLOWER

MOTOR

PLUG

6

5

4

3

2

1

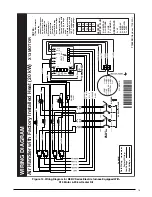

WIRING DIA

GRAM

710587B

(Replaces 710587A)

Air Handler with F

actory Installed Heat (8 kW, 10kW)

Legend

Field

Wiring

Factory

Wiring:

Lo

w

Vo

ltag

e

High

Vo

ltag

e

W2 W1 O Y/Y2

G R C

TRANSFORMER

24

V

BL

AC

K

RED

WHIT

E

BLA

CK

WHIT

E

FUSE

L2 COM 2

L2

L2 COM

L1

VS POWE

R

XFMR

COOL

HEA T

24 VA

C

RED

COM

GREY

P3

HEA

TER KIT

PLUG

Y1

NO

TES

1)

The blo

wer motor speed tap

connection ma

y not be as

sho

wn.

See the Installation

Instructions.

2) Disconnect all po

wer bef

ore

servicing.

3)

Transf

ormer ma

y ha

ve a dual

voltage primary tap.

Match the

tap position with the suppl

y

voltage used.

4)

If the Internal wiring is

replaced

, use on

ly

105

°

C

copper wire of the same

gauge

.

3

2

1

6

5

4

7

BLACK

RED

ELEMENT

BLACK

GREY

BLACK

POWER

PLU

G

LIMIT

RED

RED

RED

RED

RED

BLACK

RELAY

RELAY

TERMINAL

BLOCK

(f

or select

models onl

y

)

CIRCUIT

BREAKER

(Cir

cuit breaker

models only)

ELEMENT

4 SP

D.

MO

TO

R

1 2 3

5 6

4

1 = CO

M

2 = HIGH 3 = MED HIGH 4 = MED LOW 5 = LOW 6 = OPE

N

BR

OW

N

1 = COM

2 = HIGH

3 = MED HIGH

4 = MED LO

W

5 = LO

W

6 = OPEN

GREY

BLUE

ORANGE

GREY

ORANGE

BLUE

¢710587D¤

BLACK

BLACK