9

Figure 8. Unit horizontally Suspended

Threaded

Rod

Lag

Bolt

Nuts (x2)

Washer

and

Lockwasher

Nuts (x2)

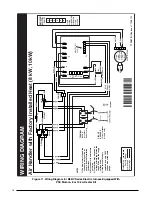

ELECTRICAL CONNECTIONS

WARNING:

ELECTRICAL ShOCK, FIRE OR EXPLOSION

hAZARD

Failure to follow safety warnings exactly could

result in serious injury or property damage.

Improper servicing could result in dangerous

operation, serious injury, death or property

damage.

• Before servicing, disconnect all electrical power

to the electric furnace.

• When servicing controls, label all wires prior

to disconnecting. Reconnect wires correctly

.

• Verify proper operation after servicing.

Electrical power wiring must be made in accordance with

all applicable local codes and ordinances, and with the

current revision of the National Electric Code (ANSI/NFPA

70). For Canadian installations, the electrical connections

and grounding shall comply with the current Canadian

Electrical Code (CSA C22.1 and/or local codes).

Pre-Electrical Checklist

√

Verify the voltage, frequency, and phase of the supply

source match the specifications on the unit rating plate.

√

Verify that the service provided by the utility is sufficient

to handle the additional load imposed by this equipment.

See the unit wiring label or Table 4 (page 15) for proper

high and low voltage wiring.

√

Verify factory wiring is in accordance with the unit

wiring diagrams (Figures 11-14, pages 16-19). Verify no

connections came loose during shipping or installation.

Line Voltage

•

An electrical disconnect must be located within

sight of and readily accessible to the unit

. This

switch shall be capable of electrically de-energizing

the outdoor unit control voltage. See unit data label for

proper incoming field wiring. Any other wiring methods

must be acceptable to authority having jurisdiction.

• It is recommended that the line voltage to the unit be

supplied from a dedicated branch circuit containing the

correct fuse or circuit breaker for the unit.

• The installer should become familiar with the wiring

diagram/schematic before making any electrical

connections to the unit. See the unit wiring label or

Figures 11-14 (pages 16-19).

The unit may also be installed in a horizontal application

with the unit suspended from the ceiling. If suspending the

electric furnace from the ceiling, assemble a support frame

using slotted iron channel and full threaded rod. Fasten

the frame together with nuts, washers, and lockwashers.

Secure the support frame to the rafters with lag bolts.

The electric furnace can also be suspended using steel

straps around each end of the unit. The straps should be

attached to the electric furnace with sheet metal screws

and to the rafters with bolts.

To attach the supply air duct to the electric furnace, bend

the perforated flanges (Figure 5, page 8) upward 90° with

a pair of wide duct pliers. Position the duct against the

electric furnace, align the openings, and secure together

with sheet metal screws. Make sure the screws penetrate

the sheet metal casing and flange. Tape or seal all seams

if required by local code.

To attach the return air duct to the electric furnace, position

the duct against the electric furnace, align the openings,

and secure together with sheet metal screws. Make sure

the screws penetrate the sheet metal casing and electric

furnace. Tape or seal all seams if required by local code.

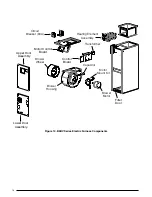

A/C or h/P Coil Installation

Approved air conditioning and heat pump system

components are listed on the unit nameplate. To install

the indoor coil:

1. Remove door cover plate, door and coil close-off plate

(with insulation). Discard door cover plate.

2. Upflow Applications: Slide the coil into the track located

in the bottom of the unit.

Downflow Applications: The downflow adaptor must be

used (see Table 1). Install the downflow adaptor and coil

as directed in the instructions supplied with the kit.

3. Reinstall the door and coil close-off plate (with insulation).

NOTE:

In downflow applications the door is rotated 180°

so that the refrigerant and condensate lines remain on

the left side.

4. Install the refrigerant and condensate lines as directed

in the instructions supplied with the outdoor unit.

NOTE:

The drain pan MUST be drained with field

supplied tubing and looped to form a trap. Both drain

tubes must have a minimum diameter of 3/4” and be

trapped separately.

IMPORTANT:

Failure to install a trap

may result in condensation overflowing the drain pan,

resulting in substantial water damage to surrounding

area.