24

440 01 2020 01

!

Maintain a minimum of 36

²

between combustion air inlet

and clothes dryer vent. Terminate the combustion air

intake as far as possible from any air conditioner, heat

pump, swimming pool, swimming pool pumping,

chlorinator or filtration unit.

CAUTION

CARBON MONOXIDE POISONING HAZARD.

Failure to properly vent this furnace can result in death,

personal injury and/or property damage.

!

1. Install all couplings, nipples and elbows using proper proce-

dures for

Joining Pipe and Fittings

and maintain spacing

between vent and combustion air piping as indicated in

Figure 19

through

Figure 26

.

8” *MIN.

20’ MAX

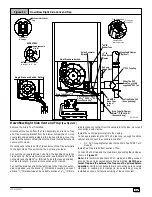

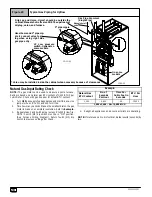

Figure 19

Sidewall Termination 12

²

or More

Above Snow Level or Grade Level

*18, Minimum for cold climates

(substained below 05 F)

Horizontal Termination

1. Cut two holes. 2

1

/

2

²

for 2

²

pipe, 3

²

for 2

1

/

2

²

pipe, or 3

1

/

2

²

for

3

²

pipe. Do

NOT

make the holes oversized, or it will be nec-

essary to add a sheet metal or plywood plate on the outside

with the correct size hole in it.

2. Check hole sizes by making sure it is smaller than the cou-

plings or elbows that will be installed on the outside. The

couplings or elbows

MUST

prevent the pipe from being

pushed back through the wall.

3. Extend vent pipe and combustion air pipe through the wall

3

/

4

²

to 1

²

and seal area between pipe and wall.

4. Install the couplings, nipple and termination elbows as

shown and maintain spacing between vent and combustion

air piping as indicated in

Figure 19

and

Figure 20

.

A metal shield is recommended 18

²

x 18

²

min. or 18

²

min. diameter

around the vent termination at the exterior wall to protect the house

exterior materials from flue product or condensation (freezing)

damage.

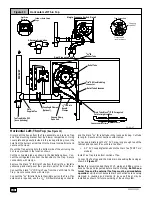

Using Exterior Risers

1. Install elbows and pipe to form riser as shown in

Figure 20

.

2. Secure vent pipe to wall with galvanized strap or other rust

resistant material to restrain pipe from moving.

3. Insulate pipe with Armaflex or equivalent moisture resistant

closed cell foam insulation or Fiberglass insulation if boxed

in and sealed against moisture.

8” * MIN.

20’ MAX

Figure 20

Sidewall Termination with Exterior

Risers to Get Above Snow Level or Grade

Level

*18, Minimum for cold climates

(substained below 05 F)

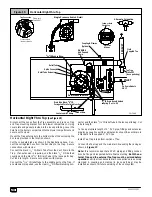

Vertical Termination

1.

Figure 21

shows the proper installation and clearances for

vertical vent termination. The vertical roof termination

should be sealed with a plumbing roof boot or equivalent

flashing. The inlet of the intake pipe and end of the exhaust

vent must be terminated no less than 12

²

above the roof or

snow accumulation level, and 12

²

away from a vertical wall

or other protrusion.

2. If the vent system is installed in an existing chimney make

sure clearances shown in

Figure 21

are maintained. Hori-

zontal section before the termination elbow can be extended

on the inlet air to provide necessary clearance.

Figure 21

Rooftop Termination

25--00--06

A

A

B

A = 12

²

Above roof or snow accumulation level

B = 8

²

Min., 20

¢

Maximum, except in areas with extreme

cold temperatures (sustained below 0

°

F), the 18

²

Min.

Vent Termination Shielding

Under certain wind conditions some building materials may be af-

fected by flue products expelled in close proximity to unprotected

surfaces. Sealing or shielding of the exposed surfaces with a corro-

sion resistant material (such as aluminum sheeting) may be re-

quired to prevent staining or deterioration. The protective material

should be attached and sealed (if necessary) to the building before

attaching the vent terminal.

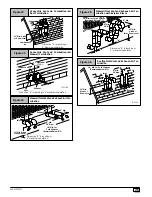

Multi Vent Termination Clearances

When two (2) or more furnaces are vented near each other, each

furnace must be individually vented.

Two (2) vent terminations may be installed as shown in

Figure 22,

Figure 23, Figure 24, Figure 25, Figure 26 and Figure 27

, but

the next vent termination must be at least 36

²

away from first 2 ter-

minations. It is important that vent terminations be made as shown

to avoid recirculation of flue gases.

Summary of Contents for 9MPT050F12A

Page 46: ...46 440 01 2020 01...