Page 8

Instruction Manual, Toftejorg SaniMidget Retractor

IM-TE91A750-EN1

Technical Data

Weight of machine

:

See table below

Working pressure

:

2-5 bar (29 – 73 psi)

Recommended pressure

:

2-4 bar (29 –58 psi)

Max. working temperature

:

95° C (203° F )

Max. sterilisation temperature

:

121° C ( 250° F)

Max. tank temperature

:

150° C (304° F)

Effective cleaning radius

:

Materials, products area

:

AISI 316L, PEEK, Sealing: EPDM

Materials, non products area

:

AISI 304, POM, Sealing: NBR

Polymers FDA-approved 21 CFR § 177

Surface finish

:

Product contacts surfaces: Ra=0.8 µm – except weldings

:

Self-lubricant with the cleaning media

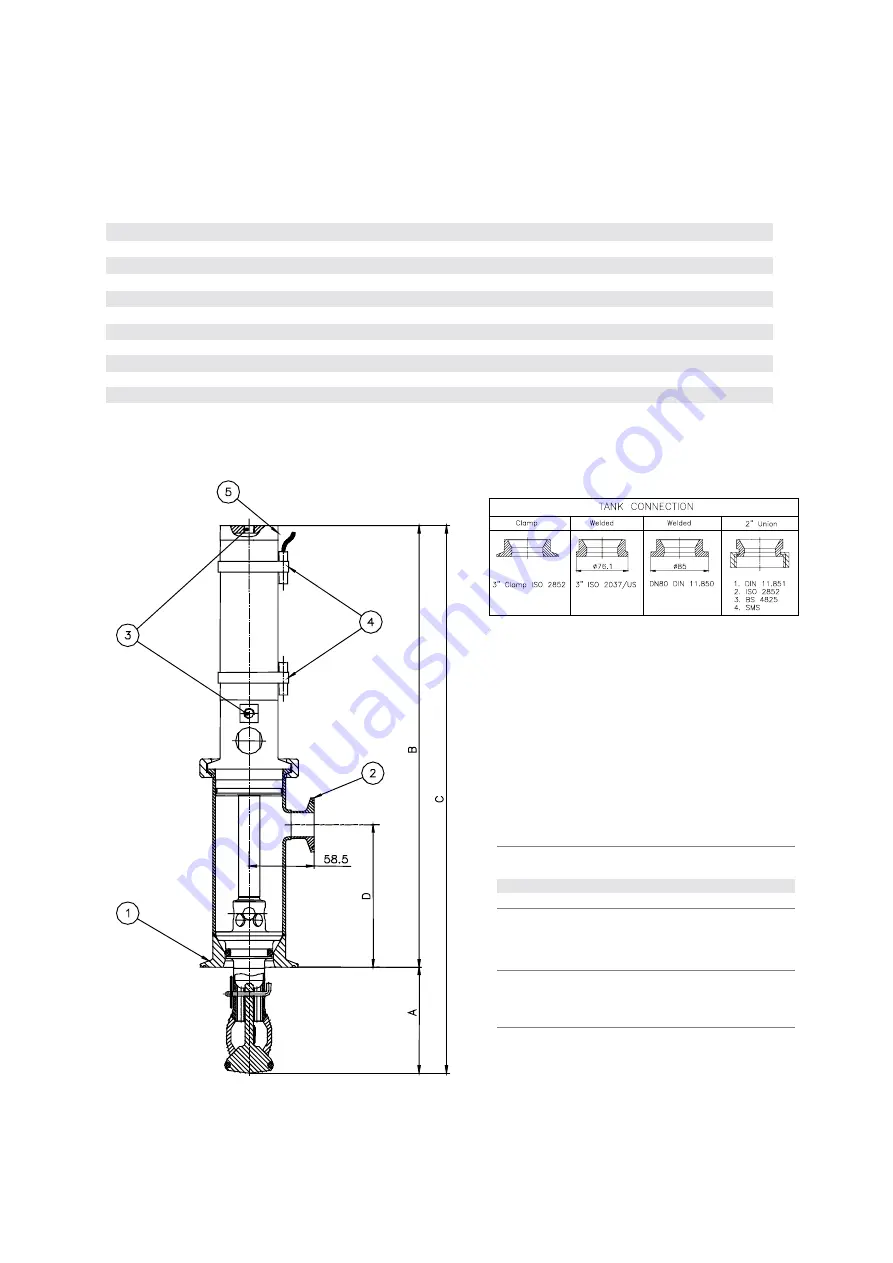

Principal Dimensions in mm

Connections

➀

➀

➀

➀

Tank connection

➁

➁

➁

➁

Inlet connection, cleaning media

1” Clamp ISO 2852

➂

➂

➂

➂

Air supply – pneumatic driven only

ISO 228-G 1/8

➃

Option

Magnetic sensor

➄

Adjustable valve – media driven only

Pneumatic version

Dimensions (mm)

Stroke

A

B

C

D

Weight

100

100

410

510

133

5.0 kg (11.0 lbs)

150

150

510

660

183

5.5 kg (12.1 lbs)

250

250

710

960

283

6.4 kg (14.1 lbs)

Media driven

Dimensions (mm)

Stroke

A

B

C

D

Weight

100

100

491

591

133

5.6 kg (12.4 lbs)

150

150

621

771

183

6.3 kg (13.9 lbs)

250

250

869

1119

283

7.4 kg (16.3 lbs)

Summary of Contents for TE91A750-EN1

Page 1: ...Instruction Manual Toftejorg SaniMidget Retractor IM TE91A750 EN1 August 2004 Return to menu...

Page 3: ......

Page 8: ...Instruction Manual Toftejorg SaniMidget Retractor Page 7 IM TE91A750 EN1 Blank page...

Page 14: ...Instruction Manual Toftejorg SaniMidget Retractor Page 13 IM TE91A750 EN1 Blank page...