Limit negative

pressure<

0.08MPa

1)Holder mouth leakage

2)Leakage on

connecting points

3)Regulating valve

loose or released

4)Surrounding

atmosphere is not as

required.

1)Remove dirt, tighten or

change the holder cover,

seal ring, and connector

2)Re-tighten each connection

point

3)Turn tightly the regulating

valve

4)Move the machine to the

required atmosphere

Change the

broken

suction

catheter

Solution

Remark

Probable reasons

Problem

Trouble shooting

9

8

Maintenance

It is recommended to have the suction tube suctioned small amount of

clean water for cleaning up the inner wall before switching off the aspirator.

After use, empty the holder, clean up dirt on the holder and plug with soft

brush or rag, flush it with water and conduct sterilization. (including the

overflow device, the seal ring and various tubes. Unscrew the overflow

device, and separate the float from its support for completely cleaning up, if

necessary. (Note: The rubber valve clack shall not be separated from the

float.)

Use the physiological saline to clean out the residual strong phlegm and

mucus in the tube after used. Replace the suction catheter if not smooth. It

is recommended to adopt one-time suction catheter.

Place the holder, cover and all tubes into the disinfectant compounded with

the KONVIDA disinfector tablets (0.5 g per tablet) in 1:500 concentration for

1 hour

Note: Keep the holder away from any sharp utensils to avoid drop in the

process of cleaning and application.

Wipe the case outer surface with lightly wet rag already soaked in the

disinfectant, and prevent any liquid seeping into the pump. Never wipe the

places marked with letters and patterns.

Place

the machine in dry and clean places, and periodically start running once a

time

(normally one time every 6 months).

Note

: Install the overflow device, conductor and other tubes as per the

connecting

mode before re-use.

Note: The dismantling & repair on the pump body if fault shall be conducted

by the specialized worker. Please contact the manufacturer if required.

1)Repair or change the socket

2)Replace the indicator

Normal power

voltage, but

the indicator

doesn't

illuminate

1)Loose socket

2)Indicator damaged

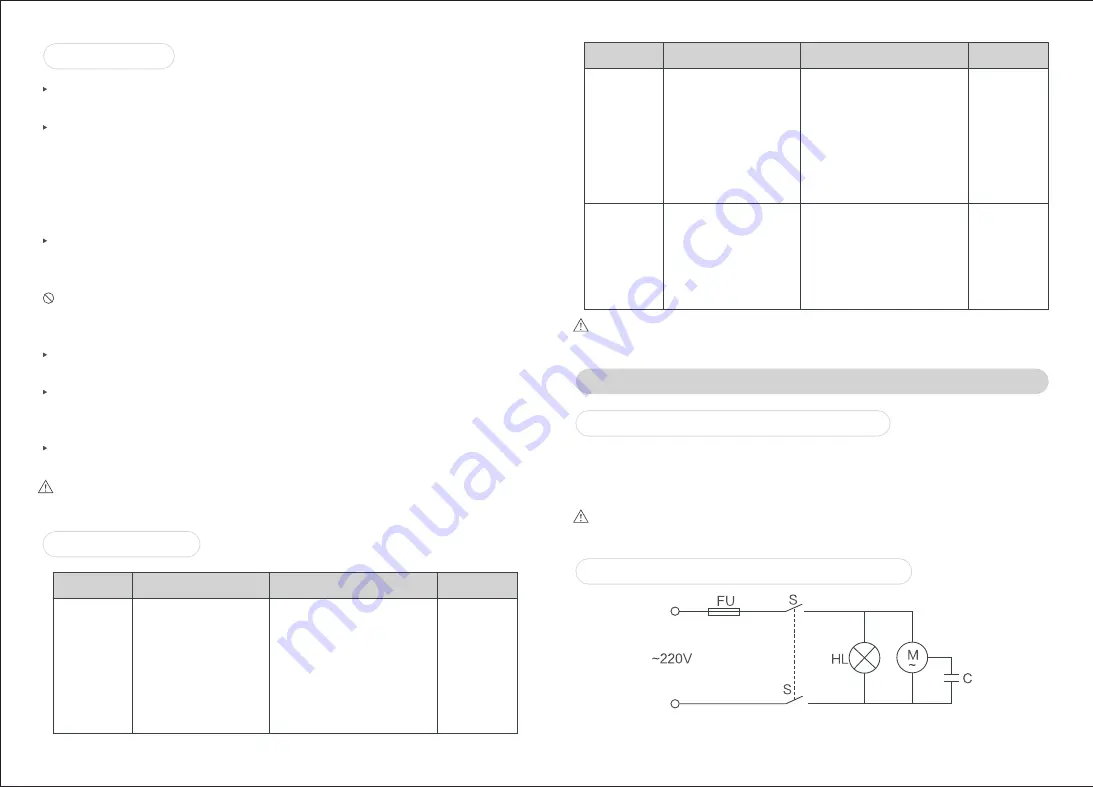

By the

specialized

maintenance

worker(Refer

to Electric

Systematic

Diagram)

1)Overflow device

shut-off

2)Tube blockage

3)Air filter blockage

Negative

pressure >

0.04 MPa,

with distinct

reduction or

disappearing

of suction

force at tube

outlet

1)Empty the

holder timely

1)After shut-off, turn the

regulating valve loose

counterclockwise to release

negative pressure in tube,

then re-screw

2)Dredge, clean or replace the

tube

3)Replace it with air filter

produced by us.

Solution

Remark

Probable reasons

Problem

Precautions

Transportation and storage conditions

Enviroment Temperature: -40℃~+55℃

Relative Humidity: 10%~93%

Atmospheric Pressure: 700hPa~1060hPa

Note: It is required to store the aspirator in the well-ventilated room without

corrosive gas, and avoid any violent shock while handling.

Electric repair to be conducted by the specialized operator.

Figure 3: Electric Systematic Diagram

Electric systematic diagram(See Figure 3)