8

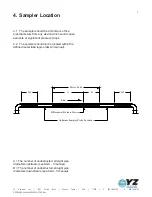

5.1 DynaPak-2010RX With Slipstream Kit

a. Mount the DP-2010RX with slipstream

kit on a vertical 2" pole.

b. Connect the slipstream adapter to the

pipeline product supply and product

return connections as shown in the

diagram.

c. Connect the actuation gas supply

(75 psi) to the actuation gas connection

located on the left hand side of the

sampler.

d. Connect the sample out connection to

the sample vessel.

e. Before applying pipeline pressure to the

DP-2010RX, ensure that the product supply

valve is closed.**

f. After pipeline pressure has been applied to

the sampler, check the slipstream tubing

connections for leaks.

g. Open the product supply valve.

h. Follow the "Operational Check and Leak

Testing Procedures" detailed in Section 7.

5. System Installation

**CAUTION

Incorrect operation of valves (over tightening) can result in damage to the valve components

(isolation valve bonnet assembly) which might result in the valve stem being screwed out of the

probe body. This of course results in product at pipeline pressure being vented continually

through this port until this section of the pipeline is shut in. Be aware of the following proce-

dures and information.

· DynaPak valves are of soft seat design and

should only be closed or opened with fingers.

No wrenches should ever be used.

· If a valve will not seal off with finger tight

operation the valve should have maintenance

performed to allow proper operation of the valve.

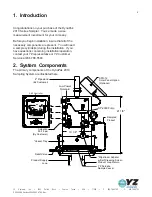

Element

(Optional)

Loop Driver

w/Static Mixer

(Optional)

(By Customer)

*Vessel Tray

Product Supply

Relief Valve

Static Mixing

Loop

Actuation

50-75 psi

(By Customer)

2" Pipestand

(Optional)

Pressure Switch

SPO-12

*Slipstream Adpater

w/Self-Cleaning Screen

Sample Vessel

YZ Durasite

Product Loop Return

Sampled

Product

Solar Panel Option

(Optional)

21 1/8"

10 1/4"

FLOW

1000

500

2000

psi

1500

PreCharge

300

250

2 75

225

80%

175

200

150

Pulse Input Module

Y−Z INDUSTRIES, INC.

BOX 89 0 S NY DE R, TEXAS 79550

P IM-100

Fa cto ry

A ppr oved

Syste m

Mu tu al

FLOW

100

125

75

25

50

0

Product

1000

500

2000

psi

1500

ps

i

19 49

F actory

S ystem

A p pr ov ed

M utual

YZ SYSTEMS, IN C.

3101 POL L OK DRIV E CONRO E, TE XAS 77303

Z -65 C on trolle r

y

P atents 5,1 52, 678; 4 ,53 1,89 5; 4,9 28, 536

Z-65 Controller