YZ Systems, Inc. • 3101 Pollok Drive • Conroe, Texas • USA • 77303 • P: 936.788.5593 • F: 936.788.5720

Page 31

DP-2010FU ver.04202004

SSSSS

ECTION

ECTION

ECTION

ECTION

ECTION

9:

9:

9:

9:

9: S

S

S

S

S

Y

YY

Y

YSTEM

STEM

STEM

STEM

STEM

O

O

O

O

O

PERA

PERA

PERA

PERA

PERATION

TION

TION

TION

TION

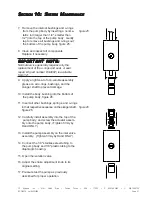

Preparing The System for Operation

1. When all of the tubing connections have

been completed, close the purge valve on the

front of the sampler probe body. Open the

sample probe supply valve to allow pipeline

pressure into the sampler,

Check all connections using a liquid

leak detector.

2. Adjust the filter/regulator from the following

ranges,

Pipeline Pressure

Actuation Pressure

Under 700 psig (48 Bar)

50 psig (3.5 Bar)

Over 700 psig (48 Bar)

65 psig (4.5 Bar)

3. Turn the stroke adjustment knob on the top of

the pump counterclockwise to set the pump

displacement at .4 cc/stroke,

4. Move all of the mode switches on the Z-65 to

their off positions, figure 20.

5. Move both timer/counter dials to the 0 posi-

tion (00 minutes), figure 21.

6. Move mode switches 1, 2 and 3 to the on

position. The pump will begin stroking once

every 2 seconds in a diagnostic test mode,

figure 22.

7. Allow the sampler to operate until the pipeline

pressure plus 100 psi (6.9 Bar) is achieved

at the sample discharge.

8. Return the mode switches to their off posi-

tions, figure 23.

9. Check all connections from the sampler

discharge to the connection on the sample

cylinder using a liquid leak detector.

10.If no leaks are found, the pump and tubing

should be considered tested and functional.

NOTE: Black indicates

the switch position.

Mutual

System

Approved

Factory

figure 19

figure 20

figure 23

figure 22

figure 21