YZ Systems, Inc. • 3101 Pollok Drive • Conroe, Texas • USA • 77303 • P: 936.788.5593 • F: 936.788.5720

Page 35

DP-2010FU ver.04202004

SSSSS

ECTION

ECTION

ECTION

ECTION

ECTION

10:

10:

10:

10:

10: S

S

S

S

S

Y

YY

Y

YSTEM

STEM

STEM

STEM

STEM

M

M

M

M

M

AINTEN

AINTEN

AINTEN

AINTEN

AINTENANCE

ANCE

ANCE

ANCE

ANCE

Preventative Maintenance

Schedule

A preventative maintenance program serves to antici-

pate maintenance issues prior to waiting until the system

requires service. Like changing the oil & filters in an

automobile, by choosing to service the various parts and

operation in the Sampling System at regular intervals,

the technician can perform the maintenance service

when desired, rather than when required, such as in the

middle of night.

The key is to perform maintenance before it is required.

The preventative maintenance schedule implemented

should consider the application of the sampler. Many of

these considerations include: the weather environment;

the condition of, the actuation gas, the product condition

and quality, and the pump stroke frequency. All of these

issues must be considered when establishing a preven-

tative maintenance schedule.

Recommended Maintenance Schedule

Monthly Inspection

1. Verify system pressures

2. Check for leaks

3. Test the battery.

4. Test the system for leaks each time a fitting or

connection has been made.

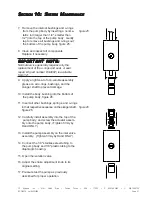

Semi-Annual Inspection

1. Clean and lubricate the sample pump

2. Check the filter element, and replacing as

necessary.

Annual Inspection

1. Rebuild pump

2. Test the Sampler System performance

and service, as needed

3. Replace Z-65 Battery Assembly.

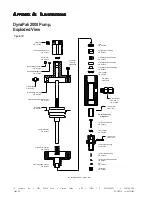

Recommended Spare Parts List

Part #

Description

Recommended

Quantity

D3-0002

DP-2000 pump seal

replacement kit

1

D3-0003

Filter Regulator repair kit

1

A4-0001

Solenoid

1

E3-2001

Z-65 Battery Assembly

1