YZ Systems Milton Roy • 201 Ivyland Road • Ivyland, Pennsylvania • USA • 18974 • P: 281.362.6500 • www.yzsystems.com

Page 91

NJEX EUR ver. 08-2021

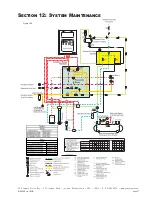

Section 13: NJEX System Troubleshooting

Verometer Expansion Tank

High Alarm Troubleshooting Steps

When an active

XTank High

alarm is indicated the

following steps should be taken:

1. Verify that the expansion tank pressure is at

1.72

Bar

and correct if necessary.

2. Inspect the alarm set point programmed into

the N-300 controller and verify that it is correclty

programmed and correct if necessary,

parameters section on programming the N-300

or

depending on the mode of operation

.

3. Observe if the alarm is still active, if it is, contact

YZ Technical Services.

Verometer Overfill Non-Alarm Indica

-

tor Troubleshooting Steps

When an active

Overfill

non-alarm is indicated the

following steps should be taken:

IMPORTANT NOTE:

Prior to troubleshooting an overfill indicator verify that

the Verometer is not in a full level position as the fill

valve commands can not be processed if the Verom-

eter is full.

1. Empty the Verometer by performing a forward

purge.

2. After returning all pressures and valves to their

normal operating position. Observe the Verom-

eter level for 5 -10 minutes and note if a change

in the Verometer level occurs without operator

influence. If level in the Verometer does increas-

es without operator influence,

Valve Trouble- shooting section of this manual on

If the level in the Verometer does not

increase then otherwise proceed to the next step

below.

3. Initiate a Verometer fill and record the time

required to fill to 100%, and note the level. If the

Verometer fills in a time faster than 30 seconds,

partially close the volume throttling valve between

the odorant storage tank and the NJEX System.

This should slow the fill rate. Repeate step 3 until

the NJEX System fills in over 30 seconds, and

the fill valve turns off between 100 - 108% of fill

volume.

Verometer Fill Rate Non-Alarm

Indicator Troubleshooting Steps

When an active

Fillrate

non-alarm is indicated the fol-

lowing steps should be taken:

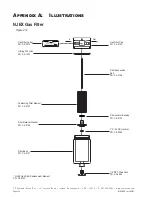

1. Verify the correct set points on the following pres-

sures.

a. Expansion Tank set at

1.72 Bar

b. Bulk Tank set at

2.07-2.41 Bar

c. System Supply set at

5.17 Bar

2. Empty the Verometer by performing a forward

purge. Re-establish the pressures and valves to

their normal operating position, and then proceed

to step 3.

3. Perform the Verometer fill procedure as indicated

Section 12: System Maintenance, page 78

and

adjust fill rate control valve

V9

to achieve a ap-

poriate fill rate.

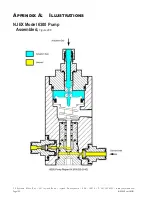

Pump Alarms

There are three pump alarms monitored by the N-300

Controller to ensure correct and safe operation of the

NJEX System. The alarms relating to the pump per-

formance and their description is as follows:

•

Over Pump

alarm will indicate if the actual pump

displacement exceeds the programed pump dis-

placement value by 30%.

•

Under Pump

alarm will indicate when the actual

pump displacement ranges from 30 - 75% of the

programed pump displacement value.

•

Pump Failure

alarm will indicate when the actual

pump displacement is less than 25% of the pro-

gramed pump displacement value.

Summary of Contents for NJEX 6300G

Page 1: ...NJEX 6300G 7300G N A T U R A L G A S O D O R I Z A T I O N S Y S T E M...

Page 2: ......

Page 3: ...NJEX 6300G 7300G Instruction Operating Manual Version 08 2021...

Page 4: ......

Page 10: ......