YZ Systems Milton Roy • 201 Ivyland Road • Ivyland, Pennsylvania • USA • 18974 • P: 281.362.6500 • www.yzsystems.com

Page 3

NJEX EUR ver.08-2021

Section 1: First Things To Know About The NJEX

Theory of Operation

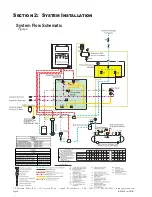

Operation of the NJEX centers around three primary

components: the pump, the Verometer and the Model

N-300G controller.

During normal operation, the pump injects an ex-

act quantity of odorant at a rate determined by the

N-300G controller. The quantity of odorant injected

per stroke is set using a spacer in the pump actuation

assembly. The rate at which the pump is actuated is

determined by the N-300G controller.

The Verometer serves as a temperature

compensated meter which verifies the amount of

odorant injected by the pump. The N-300G controller

uses an input signal from the Verometer to determine

the amount of odorant that has been injected, as well

as the odorant level within the Verometer. Once the

odorant level falls to a predetermined low level point,

the N-300G controller actuates a solenoid valve which

opens the fill valve, allowing the Verometer to be re-

filled. Once the Verometer is filled, the N-300G control-

ler closes the fill valve.

The N-300G controller allows the NJEX system to

operate in either a time-based mode or a proportional-

to-flow mode. In the time-based mode of operation,

the N-300G controller actuates the pump at a regular

time interval preset by the operator.

In the proportional-to-flow mode of operation, the

N-300G controller uses a customer provided gas flow

rate input signal and several operator input values

to calculate the time between strokes of the pump.

These operator input values include the odorant injec-

tion rate (mg/m3), pump displacement (cc/stroke), and

the odorant density (g/cc). The flow input signal is

customer provided by either a flow computer or other

flow monitoring devices. In this mode, the controller

has the capability to distinguish between a low flow

situation and a loss of flow input signal. For systems

with analog inputs, if a loss of flow signal occurs, the

controller automatically defaults back to a pre-select-

ed percentage of the flow input.

The flow input signal is read by the N-300G controller

eight times per pump stroke. These readings are aver-

aged and the time duration until the next stroke is then

calculated by the controller. The maximum time be-

tween strokes is 99.99 minutes (when gas is flowing),

regardless of the time calculated by the controller.

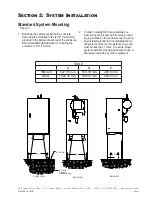

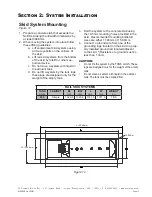

CAUTION:

Excessive tubing lengths should be avoided. Instal-

lation of the NJEX Odorization system should be as

close to the point of injection and Odorant Storage

Tank as possible. Maximum tubing length should not

exceed 4.5 meters with the tubing size maintained as

indicated in this manual. If longer tubing lengths are

required consult YZ Systems Technical Services at;

800.653.9435 or 1.281.362.6500.

System Accessories

• Odorant Injection Probe, includes a 316 stainless

steel probe, and isolation valve for location at the

pipeline. When ordering, please specify pipeline

connection required, 1/2" to 3/4".

• Odorant Injection Probe with Sightglass, includes

a 316 stainless steel probe, visual odorant sight

indicator, and an isolation valve for location at the

pipeline. When ordering, please specify pipeline

connection required, 1/2" to 3/4".

• 1/4" stainless steel discharge tubing In-line Check

Valve. For placement in the odorant discharged

tubing line immediately preceding the probe assem-

bly, (P/N A3-0024).

• 1/4" stainless steel tubing Dielectric Isolator Union.

These should be installed in every tubing line that

attaches the odorizer to the pipeline in any manner.

For example the supply gas, odorant discharge, and

differential pressure switch connections, (P/N A1-

0182).

• NJEX Scrubbers. These filters are designed to

scrub the exhaust gas vented from the pumps or

Overflow Protector of the Expansion Tank. They are

available by ordering P/N C4-0018, 15 gallon scrub-

ber.

A complete line of odorization accessories ranging

from pre-odorized gas scrubbers to injection probes is

available through YZ. Please contact your local

representative or YZ toll free at 800.344.5399. For

technical support call 800.653.9435.

Summary of Contents for NJEX 6300G

Page 1: ...NJEX 6300G 7300G N A T U R A L G A S O D O R I Z A T I O N S Y S T E M...

Page 2: ......

Page 3: ...NJEX 6300G 7300G Instruction Operating Manual Version 08 2021...

Page 4: ......

Page 10: ......