YZ Systems Milton Roy • 201 Ivyland Road • Ivyland, Pennsylvania • USA • 18974 • P: 281.362.6500 • www.yzsystems.com

Page 17

NJEX EUR ver. 08-2021

Section 3: Filling the Bulk Odorant Tank

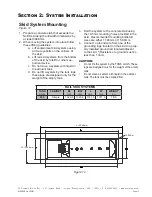

Electronic Level Indicator

Odorant Vapor Return

1/2” NPT

Odorant Fill

1/2” NPT

V15 V13

V11 V10

Filling the Tank for the First

Time

CAUTION:

Odorant has a very strong odor, which if allowed to

escape to the atmosphere, may cause problems in the

local community. Take necessary precautions when

filling an odorant storage tank to assure that the local

community is not disrupted during the filling process.

Verify that the entire system has no pressure in it

before beginning. Additionally, all personnel should

wear protective clothing, and use equipment as

recommended by the chemical manufacturer during

this time. If you are uncertain about any aspect of the

odorant itself, you should contact the manufacturer of

your chemical prior to proceeding.

1. Verify correct position of valves before beginning,

figure 15

.

Open:

V13*

Closed:

V10

,

V11

, and

V15

*Note Gas Supply to V13 should NOT be turned

on during this procedure.

2. Attach inert or natural gas supply to

V10

.

Section 3: Filling the Bulk Odorant Tank

3. To purge the tank open valve

V10

to introduce

inert or natural gas to the tank to begin displacing

any ambient air from the empty tank. Continue

until pressure on the gage located directly above

V13

is observed, then partially open

V11

to allow

ambient air from the tank to begin flowing out.

Allow this process to continue until all ambient

air from the tank is purged, and only inert gas or

natural gas is emitting from this valve, then close

V11

and

V10

. The time required to accomplish

this task will vary with the tank size.

4. Vent purge gas by opening

V11

partially until tank

pressure just reaches zero, and then close

V11

.

5. Attach odorant supply to

V10

, open

V10

, and

begin transferring odorant to the bulk tank.

6. Connect a line from

V11

to a flare or vapor recov-

ery device, and open

V11

.

CAUTION:

Fill tank to a maximum level of 80% of the tank capacity.

7. Close

V10

and

V11

, and remove odorant trans-

fer equipment, and line to flare or vapor recovery

device.

8. Continue through the remaining procedures in this

manual.

Figure 15

Summary of Contents for NJEX 6300G

Page 1: ...NJEX 6300G 7300G N A T U R A L G A S O D O R I Z A T I O N S Y S T E M...

Page 2: ......

Page 3: ...NJEX 6300G 7300G Instruction Operating Manual Version 08 2021...

Page 4: ......

Page 10: ......