YZ Systems Milton Roy • 201 Ivyland Road • Ivyland, Pennsylvania • USA • 18974 • P: 281.362.6500 • www.yzsystems.com

Page 63

NJEX EUR ver. 08-2021

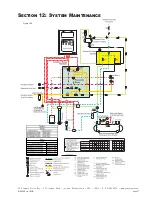

Section 10: Mechanical System

Figure 174

The threaded inlet connection to the fill valve allows

access to the check valve wafer, return spring, and

o-ring seal without disturbing the diaphragm and its

seals.

Verometer

The purpose of the Verometer,

figure 174

, is to act

as an odorant meter, verifying the amount of injected

odorant. The Verometer contains a level monitoring

device allowing the N-300G controller to compare the

actual amount of odorant injected to the displacement

setting of the pump. The N-300G also controls filling

the Verometer and activating the Verometer alarm

functions based on input from the level monitoring

device.

Odorant enters the Verometer from the fill valve.

Odorant exits the Verometer by passing through a

second filter element on its way to the pump. The filter

element is held in place by the filter plug located at the

bottom of the Verometer.

The upper portion of the Verometer, above the odor-

ant fluid level, is connected to the expansion tank by

stainless steel tubing and the odorant discharge mani-

fold. The purposes for this configuration are:

1. The Verometer / expansion tank connection

provides a closed loop system which prevents

odorant escape into the atmosphere.

2. As the Verometer is filled, pressure builds within

the closed Verometer / expansion tank system.

The additional volume provided by the expansion

tank prevents the accumulating pressure in the

Verometer from equaling the blanket gas pressure

in the odorant storage tank. This ensures an un-

interrupted flow of odorant from the storage tank

to the Verometer.

Summary of Contents for NJEX 6300G

Page 1: ...NJEX 6300G 7300G N A T U R A L G A S O D O R I Z A T I O N S Y S T E M...

Page 2: ......

Page 3: ...NJEX 6300G 7300G Instruction Operating Manual Version 08 2021...

Page 4: ......

Page 10: ......