YZ Systems Milton Roy • 201 Ivyland Road • Ivyland, Pennsylvania • USA • 18974 • P: 281.362.6500 • www.yzsystems.com

Page 88

NJEX EUR ver. 08-2021

Section 13: NJEX System Troubleshooting

Verometer No-Fill Alarm

Troubleshooting Steps,

Continued

5. Verify that the status switch be in the run position.

If no pneumatic supply is received at the fill valve

when a fill is called for, test electrical supply to the

fill

valve solenoid located on the left. With a volt

meter the current should read 12VDC at the fill

valve solenoid when a fill is requested. If voltage

is present when a fill is requested, but gas will not

flow to the fill valve, replace the solenoid.

a. If a volt meter is unavailable, you may test

fire the pump with the test switch to verify the

other solenoid and cable are active. To test,

temporarily switch the solenoid cables. Now

when the test switch is activated, the fill valve

solenoid should send pneumatic supply gas

to the loosened connection at the fill valve for

approximately .2 seconds each time the test

switch is activated. If this does occur there

is some problem with the fill signal getting to

the fill solenoid. However, if the solenoid still

does not send actuation gas to the fill valve

the solenoid is bad and should be replaced.

If the signal is not getting to the solenoid, test at

terminal strip

TB2

, located inside the termination

enclosure just below the N-300 Controller, with a

volt meter at pins

7

positive

(orange wire)

and

8

negative

(violet wire

), for 12VDC when the fill is

requested from the N-300 controller. If the volt-

age is present, check the wiring for proper polarity

connections. Verify that pin

7

has an orange wire,

and pin

8

a violet wire connected.

6. If an electrical signal is not present when a fill is

requested, check all cables for corrosion, mois-

ture, or damage and replace if any signs of the

previous mentioned problems are present and

perform the test again.

7. If an electrical signal is still not present contact YZ

Systems Technical Service.

Verometer Slow-Fill Alarm

Troubleshooting Steps

IMPORTANT NOTE:

Prior to troubleshooting a slow fill alarm, verify that the

Verometer is not in a full level position as the fill valve

commands can not be processed if the Verometer is

full.

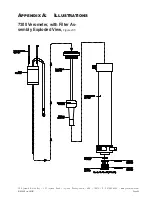

1. Inspect the actuation gas supply filter for possible

restriction, and replace as necessary.

2. Inspect the odorant filters for possible restriction

and replace as necessary.

3. Check tubing between bulk odorant storage tank

and enclosure for damage. If tubing is crimped,

bent or damaged by any form that could restrict

flow, replace the tubing. Verify that an adequate

flow of odorant is supplied to the fill valve.

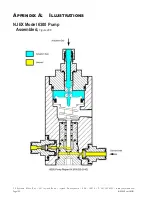

4. Test for adequate fill valve pneumatic actuation

pressure. Place a guage at the tubing connection

located on top of the fill valve by disconnecting

tubing. During a fill, the valve actuation pressure

should be

5.17 Bar

.

5. Disassemble, clean, and rebuild fill valve assem-

bly.

Verometer Leakage Alarm

Troubleshooting Steps

1. Inspect the system for any obvious leaks and

repair as necessary.

2. If the

Leakage

alarm occurs during purging of the

system or the packing of the lines with odorant on

a new system, a manual refill of the verometer will

be required and this will clear the alarm.

3. Verify that the pump displacement parameter cor-

rectly matches the actual pump performance on

the system, and correct if necessary.

4. Verify the correct balance of pressures between

the pump actuation pressure and the pipeline

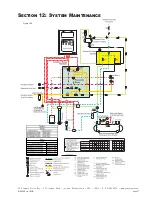

refer to figure 4, in the System Flow

Schematic on page 6, Section 2: System Installa-

for specific system pressures.

Summary of Contents for NJEX 6300G

Page 1: ...NJEX 6300G 7300G N A T U R A L G A S O D O R I Z A T I O N S Y S T E M...

Page 2: ......

Page 3: ...NJEX 6300G 7300G Instruction Operating Manual Version 08 2021...

Page 4: ......

Page 10: ......