YZ Systems Milton Roy • 201 Ivyland Road • Ivyland, Pennsylvania • USA • 18974 • P: 281.362.6500 • www.yzsystems.com

Page 9

NJEX 7300G ver.08-2018

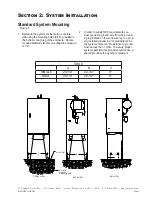

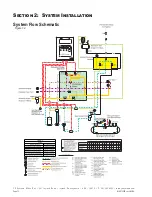

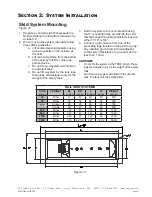

Section 2: System Installation

Figure 9

Figure 10

Optional Heater

A.C. Connection

CAUTION:

Excessive tubing lengths should be avoided. Installa-

tion of the NJEX Odorization system should be as close

to the point of injection and Odorant Storage Tank as

possible. Maximum tubing length should not exceed 15’

(4.5 meters) with the tubing size maintained as indicated

in this manual. If longer tubing lengths are required

consult YZ Systems Technical Service Department at;

800.653.9435 or 281.362.6500.

3. Connect the odorant supply source to the odorant

inlet mainfold with the recommended 1/4” stainless

steel tubing,

figure 9

. A tank isolation valve should

be incorporated between the storage tank and this

connection,

figure 9.

4. Connect the regulated actuation gas source, of 75

psi (5.17 Bar) supplied by the NJEX system owner,

to the NJEX gas filter inlet fitting using a dielectric

union,

figure 9

.

• For Pipeline pressures less than 200 psig a single

cut regulator (Fisher 67 YZ P/N A3-0042 or

similar) adjustable to provide 75 psig to the inlet

gas filter on the NJEX enclosure should be ac-

ceptable.

• P/L pressure above 200 psig need a dual cut regu-

lation process:

1. Install the primary regulator on the pipeline

*Fisher 1301 YZ P/N A3-0274 or similar),

and adjust it to provide 150 psi to the sec-

ondary regulator.

2. Install the secondary regulator at the inlet

gas filter on the back of the NJEX enclosure

(Fisher 67 YZ P/N A3-0042 or similar), and

adjust it to provide 75 psig to the NJEX Sys-

tem should be acceptable.

3. 3/8” Stainless Steel tubing should be used

between the two regulators.

• Dual Pump enclosures, may require larger tubing

between the regulators, and the secondary regula-

tor may need to have a larger orifice (Fisher 64 or

similar), if both pumps run simultaneously.

Note:

In applications where the actuation gas supply

has a high water content and/or a low hydrocarbon dew

point, additional actuation gas filtration or heating of the

7300G system may be necessary. Bottled nitrogen can

also be used during cold operating conditions to avoid

condensation in the actuation gas supply line. Also,

an actuation gas source pressure of 75 psi (5.17 Bar)

should be adequate in most installations.

5. Connect the pipeline port of the odorant discharge

manifold to the pipeline connection using a dielectric

union and check valve,

figure 9.

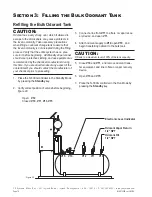

6. If a heater option was specified with this odorizer,

120 / 240 VAC electricity

, should be connected to the

electrical inlet located on the lower side of the

enclosure using 1/2” conduit and appropriate pack

off. Power requirements for the heater are

1.67A for the 120VAC heater, and .833A for the

240VAC heater. Each heater is a thermostati cally

controlled 200Watt unit, figure 10. Dual unit enclo

sures may have dual heater elements. Values

provided are per heater element.

Odorant Discharge

Manifold Pipeline Port

Odorant Inlet

Connection

75 psi (5.17 Bar)

Regulated Actuation

Gas

Summary of Contents for NJEX 7300G

Page 1: ...NJEX 7300G N A T U R A L G A S O D O R I Z A T I O N S Y S T E M ...

Page 2: ......

Page 3: ...The NJEX 7300G Instruction Operating Manual Version 08 2018 ...

Page 4: ......

Page 10: ......