17 Operation and Maintenance Manual

MQ-150 Ballscrew Feed Unit

B.

Application of Lubricants:

Make certain that the application instrument is completely clean and will

not contaminate the lubricant, dissolve or break apart into the lubricant.

Syringes and plastic spatula type devices work well for this purpose. Use

protective gloves when handling the lubricant and lubricated parts.

QUILL - Grease fitting on housing barrel provides lubrication point for

grease gun. Remove set screw on opposing side of barrel before adding

grease. Pump grease until it is visibly ejected from hole on opposing side.

Replace set screw into relief hole on opposite side. Grease fills an

undercut pocket inside of cylindrical housing.

SPINDLE BEARINGS & SPLINE SHAFT BEARINGS - For low speeds

(<2500 rpm) fill as much as 100% of bearing free space. For medium

speeds (2500 - 6000 rpm) fill 67% of free space. For high speeds (6000 -

10,000 rpm) fill 25% of free space.

BALL SCREW BEARINGS - Apply same as above spindle bearings but

fill 1/3 of free thread tooth space with lubricant

SPLINE SHAFT - Apply lubricant in a thin coat along length of spline

tooth section.

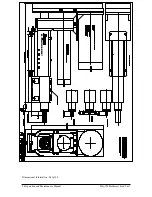

BALL SCREW - Apply the lubricant so that 1/3 of the screw thread free

space is filled (see below).