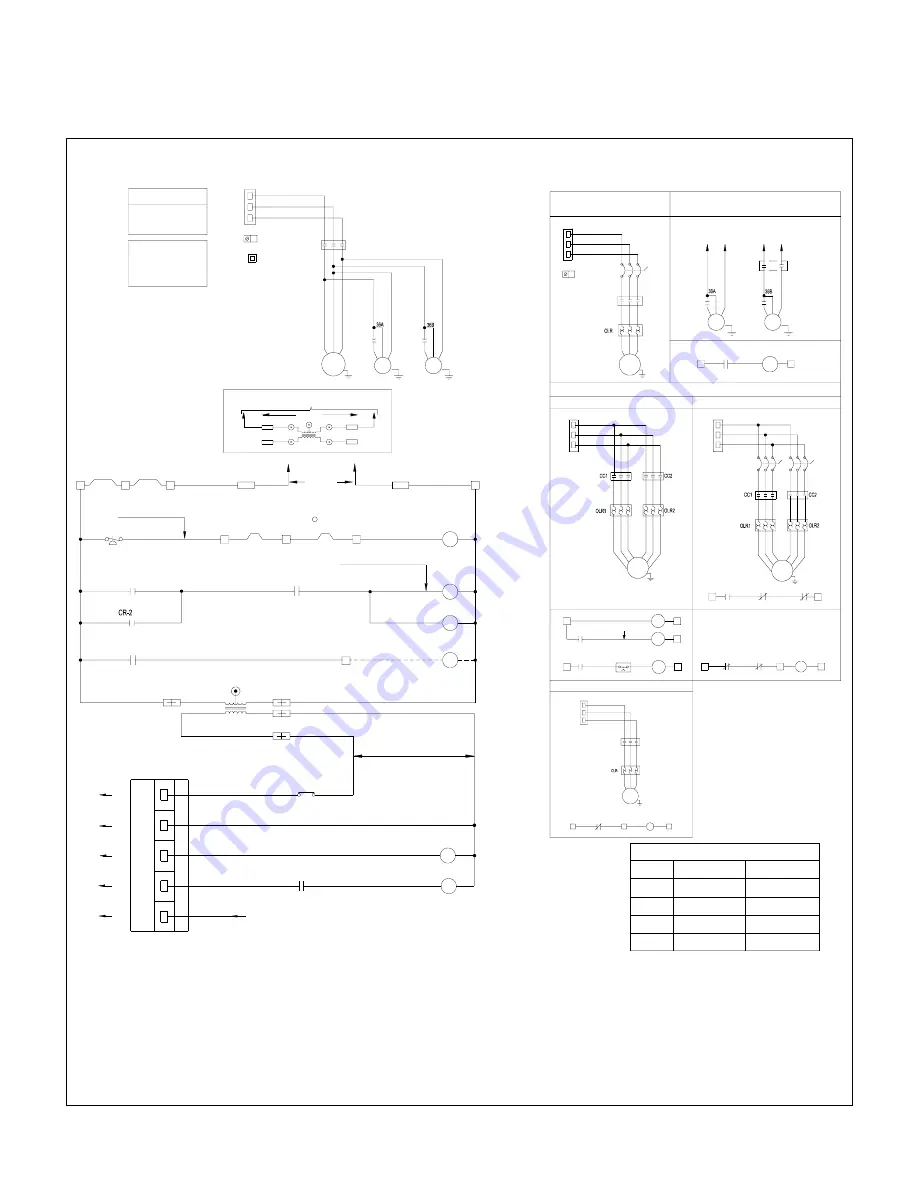

TYPICAL SCHEMATIC WIRING DIAGRAM

NOTE:

1. Refer to next page for legend, notes & wiring diagram for optional items.

2. Refer to unit control box (inside panel) for exact wiring diagram.

MODELS : CX150 (SINGLE COMPRESSOR UNITS)

9

CLOSE(PSIG)

OPEN(PSIG)

NAME

FCS

190 ± 15

290 ± 10

45

LPS1

HPS

450 ± 10

LPS 25

±

5

55

360 ± 15

50 ± 5

SET POINTS

TRANS2 CONNECTION APPLICABLE FOR 460V UNIT

L1

F1

F3

230V

460V

TRANS2

3

5

4

6

F2

F4

L3

PLS. REFER UNIT NAME PLATE

VOLTAGE CONNECT 37A,37B OF

1PH FM & L2 OF TRANS TO NTB

1.NTB IS APPLICABLE FOR

380V/3PH/60Hz

2.FOR UNIT WITH ABOVE

WRG DGM SUITS

230V/3PH/60Hz

460V/3PH/60Hz &

380V/3PH/60Hz

NOTE:

POWER SUPPLY

26A

COMP

T3A

OLR-1

27A

T1A

T2A

SR

2

73A

71A

72A

L3

CC

CC

LUG

HVTB

L3

L2

L1

35A

COMP

CAP1

FM1

CAP2

35B

36A

T1

A

T2

A

T3

A

36B

37A

FM2

37B

73

B

72

B

71

B

71A

72A

73A

OLR1-1

SR-1

COMP.CONN WITH OLR & W/OUT CB OPTION

HVTB

SEE CONN.BELOW

FOR TDS OPTION

TDS1-1SEC

CC1A-1

3A

3C

CC1A-1

3D

3A

L2

L1

3D

CC2

2

26A

CC2

CC1

2

2

T2

A

T1

A

1

COMP

2A

T1

C

T3

A

T3

C

T2

C

OLR2-1

27A

81A

SR

2

T3

C

T3

A

T1

C

T2

C

T1

A

T2

A

COMP

1

CB1-1

3E

CB2-1

3F

3A

71A

73A

72A

73

B

71

B

72

B

FCS

COMPRESSOR CONNECTION WITH PART WIND START ONLY

WITH CIRCUIT BREAKER

WITHOUT CIRCUIT BREAKER

L3

L2

L1

HVTB

L3

L2

HVTB

L1

CB

L1A

71A

T1

A

CC

LUG

73A

72A

T3

A

T2

A

COMP

3A

FM1

L3A

L2A

CAP1

35A

36A

37A

CB1

L1A

L3A

L2A

L2B

L1B

L3B

CB2

12

FMC

FM2

2

CAP2

35B

36B

37B

FMC

T2A/72A

LOW AMBIENT OPTION CONNECTION

APPLICABLE FOR 230V - 1PH FAN MOTOR

CIRCUIT BREAKER OPTION

HVTB

L1

L2

L3

TO CC

T1A/71A

T3A/73A

TO CC

T2A/72A

AHU

TO

41A USE FOR OPTION-3-B ONLY

5

4

3

2

39A

38A

1

ATB

SR-2

40A

15

CB

16

24VAC

C-PUMP DOWN SOLENOID RELAY

17

YR

PDSR

C-COOLING RELAY

JP1

[UVM]

1

F2

*

[SSPS]

[AI]

FOR COMP.CONN.WITH PART WIND START-SEE ABOVE

JP4

PDSR-1

TRANS1

YR-1

LPS

2A

24A

4A

JP6

SR-1

25A

3A

26A

ATB1

SEE HPS OPTION BELOW

JP2

1A

[SD]

1B

F1

230VAC

SEE NOTE-8

L1

L2

C-PUMP DOWN SOLENOID

PDS

C-CONTROL RELAY

CR

CC

SR

C-CONTACTOR

C-SAFETY RELAY

ATB1

2

NTB