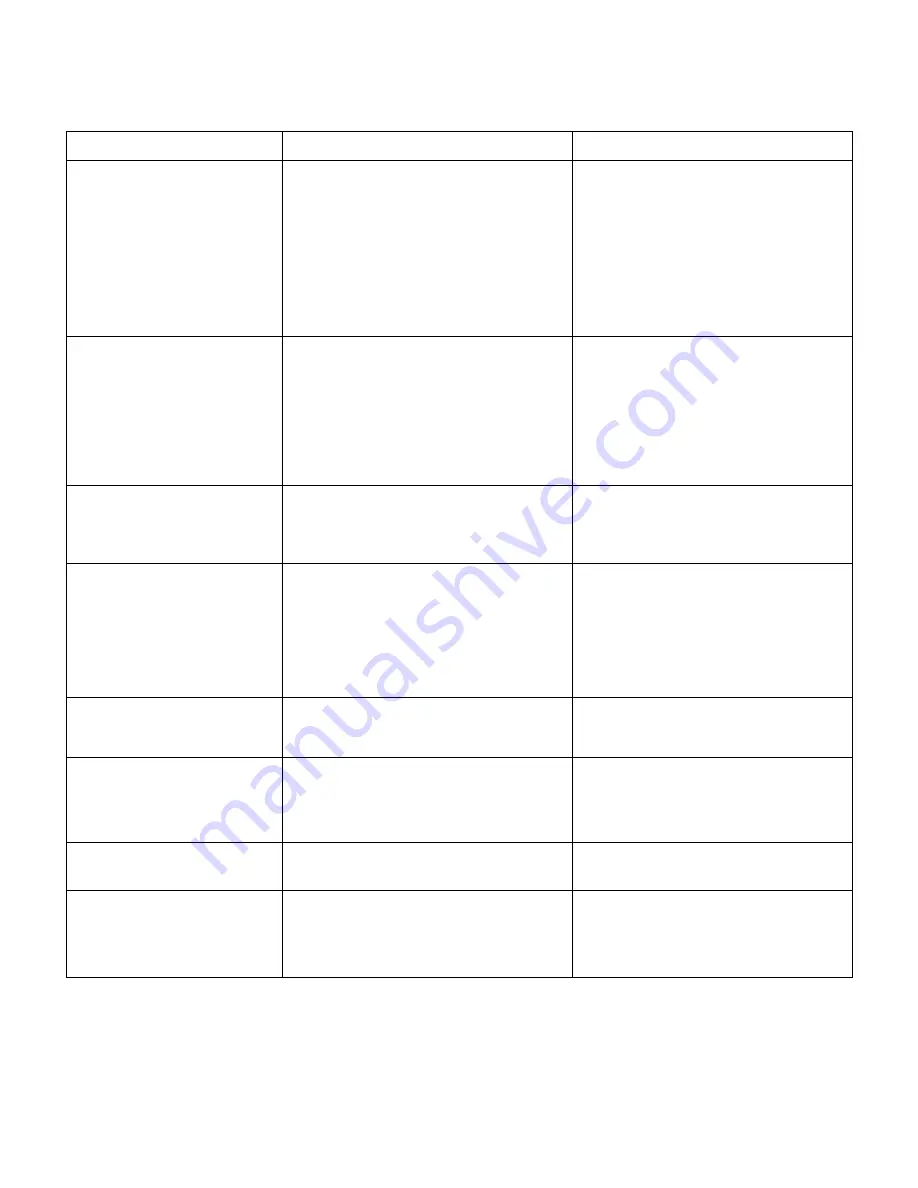

TROUBLE SHOOTING CHART

SYMPTOM

CAUSES

CHECK & CORRECTIVE MEASURE

Evaporator ices up.

Head pressure too high.

1. Restricted airflow.

2. Dirty air filter.

3. Short of refrigerant.

4. Low air volume.

5. Restricted distributor tube.

6. Restricted liquid line/low liquid line pressure.

1. Refrigerant overcharge.

2. Air in system.

3. Dirty condenser.

4. Malfunction of condenser fan (air-cooled).

5. Excessive air temperature entering condenser.

6. Restriction in discharge line.

1. Check for dirt or lint on coil.

2. Clean or replace. Advice customer on periodic

cleaning of filter.

3. Check system pressure. Take superheat read-

ing. Add refrigerant.

4. Check for dirty air filter or loose belt.

5. Check for warm distributor tube.

6. Check for restriction in lines/improve liquid line

pressure by proper charging or installing fan

cycle switch, etc.

1. Correct the refrigerant charge.

2. Recharge the system after a thorough triple

evacuation.

3. Clean.

4. Check and correct or replace.

5. Check for short circuiting of condenser dis-

charge air, correct it.

6. Correct it.

Head pressure too low.

1. Low ambient temperatures (air-cooled).

2. Refrigerant shortage.

3. Damaged valves in compressor.

1. Install fan cycling switch, if not provided. Check

the setting and operation, if provided.

2. Correct the refrigerant charge after leak testing.

3. Repair/replace the compressor.

1. Check the design.

2. Follow manufacturer's guide line and correct it.

3. Repair/replace compressor.

4. Check and adjust the superheat accordingly.

5. Check the expansion valve bulb is properly

tighten at correct location.

1. High load on evaporator. Load in excess of de-

sign conditions.

2. Unbalanced system. Oversized air handling unit

matched with under sized condensing unit.

3. Compressor discharge valve leaking.

4. Expansion valve widely open.

5. Improper bulb location or installation.

High suction pressure.

Run capacitor open, shorted or

blown.

1. Improper capacitor.

2. Excessively high line voltage (110% of rated

max.)

1. Determine correct size and replace.

2. Determine reason and correct.

Space temperature too high.

1. Control setting too high.

2. Expansion valve too small.

3. Cooling coils too small.

4. Inadequate air circulation.

1. Reset control.

2. Use larger valve.

3. Add surface or replace.

4. Improve air movement.

Liquid line frosted or sweating.

Unit noisy.

1. Restriction in dehydrator or strainer.

2. Liquid shut-off valve partially closed.

1. Loose parts or mountings.

2. Tubing rattle.

3. Bent fan blade causing vibration.

4. Fan motor bearings worn.

1. Replace part.

2. Open valve fully.

1. Find and tighten.

2. Tighten the pipe support.

3. Replace blade.

4. Replace motor.

12